Plant factory vegetable planting system and equipment

A planting system and plant technology, applied in botany equipment and methods, plant cultivation, gardening tools/equipment, etc., can solve the problems of large space occupation, no reduction of carbon dioxide, and inability to control, so as to reduce the occupied space and reduce the supply , the effect of reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in combination with the accompanying drawings and specific embodiments.

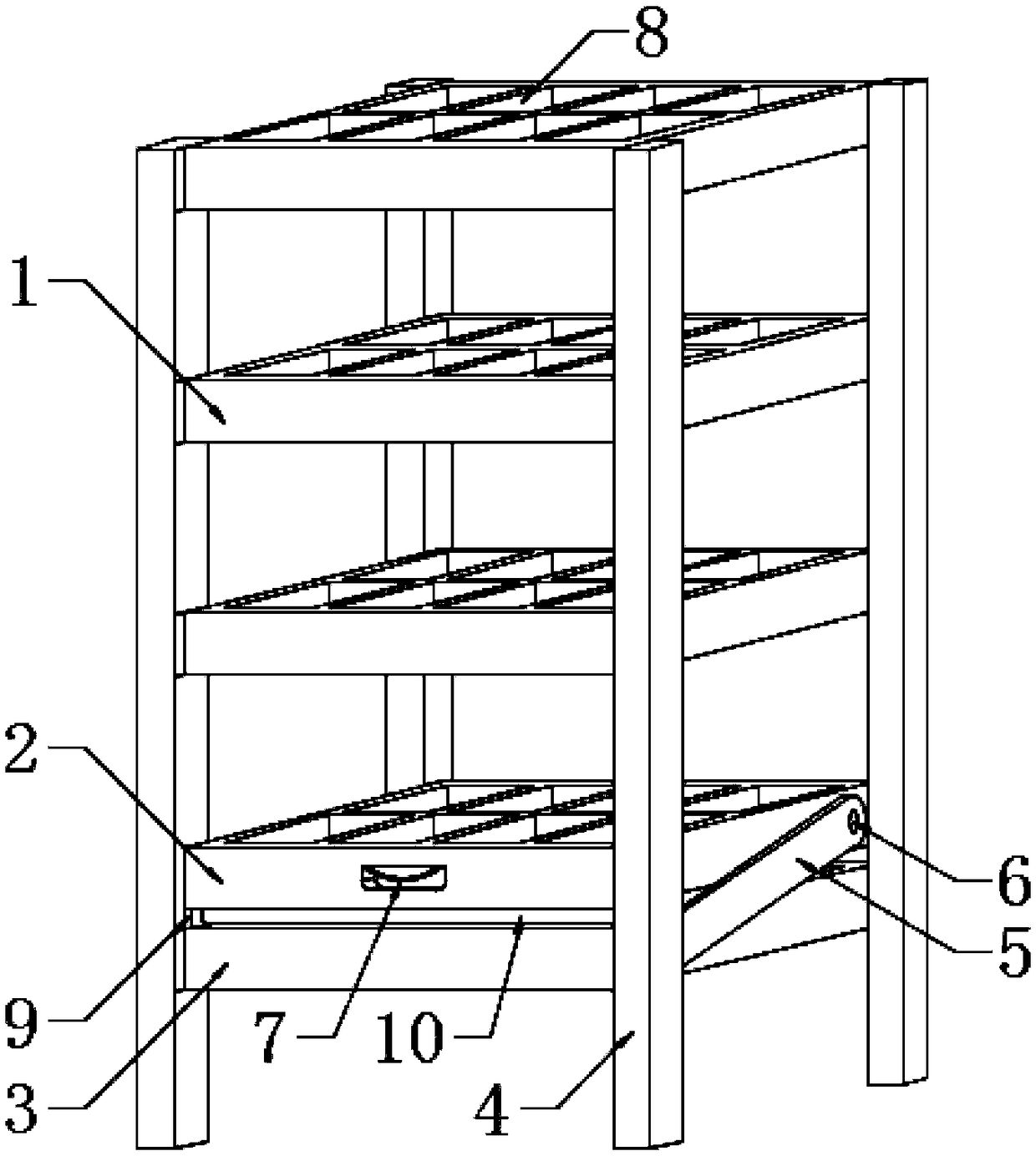

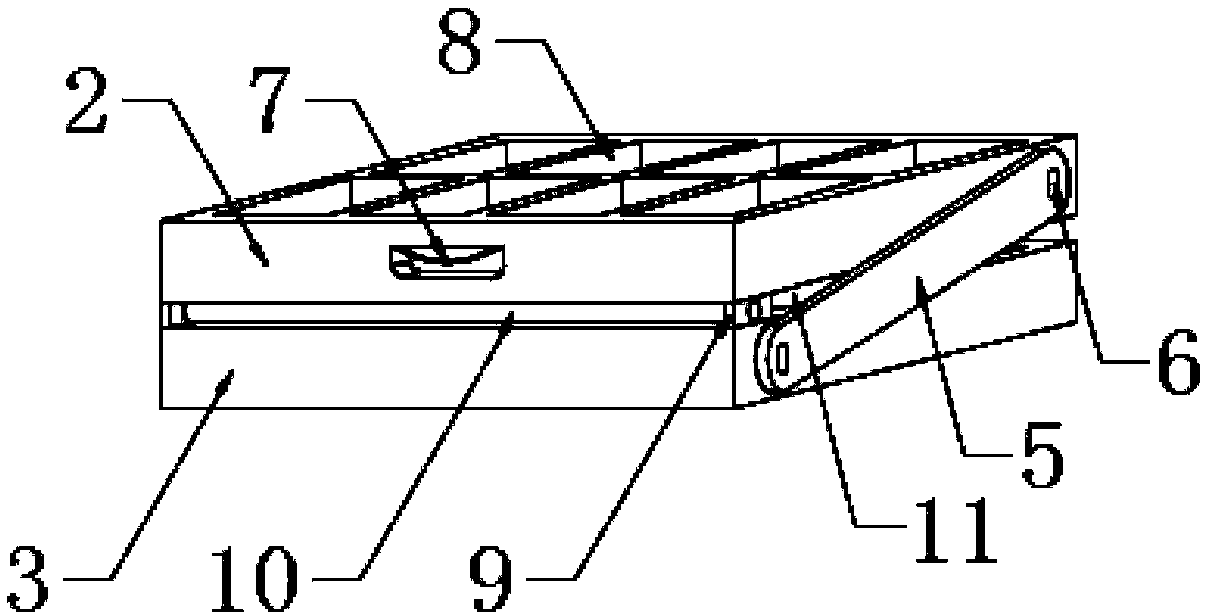

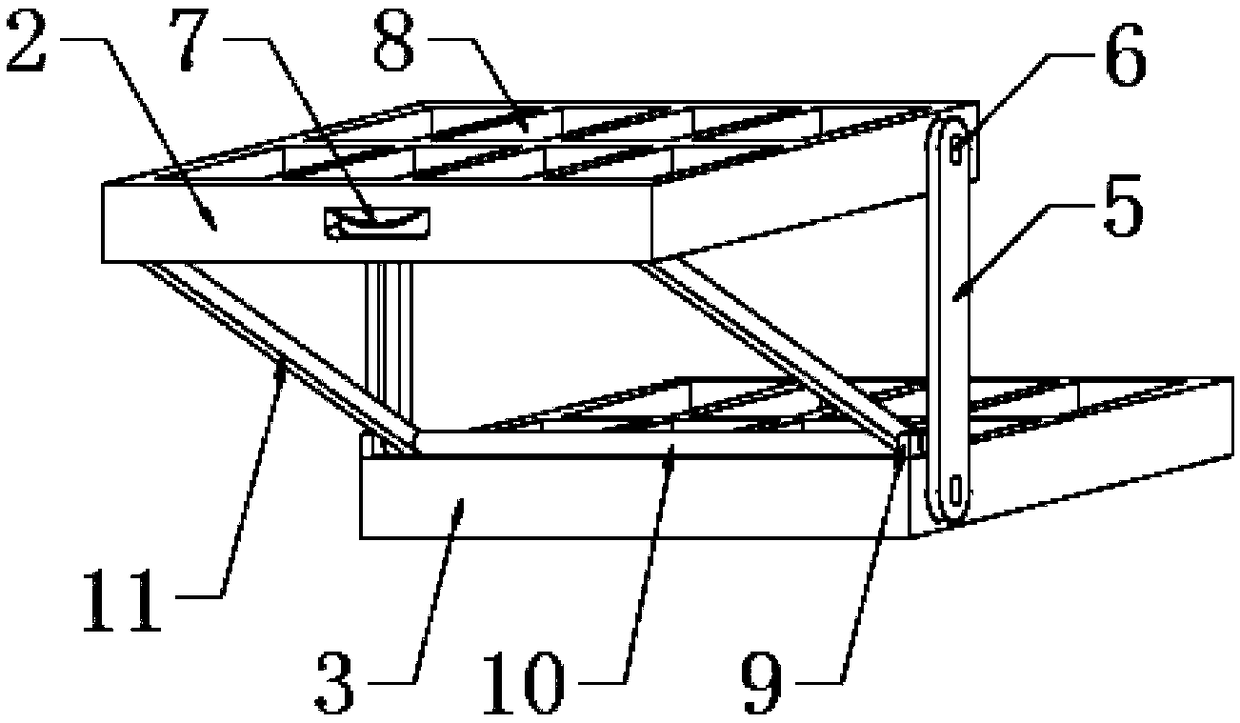

[0032] see Figure 1-7 , the present invention provides a technical solution: plant factory vegetable planting system and equipment, including plant factory 23, four plant growth racks, water circulation system, plant lighting system, temperature and humidity control system, gas circulation system, nutrient solution supply system, liquid crystal Display module 34 and key input module 35;

[0033]The plant growth frame includes four support columns 4, and three layers of evenly distributed first planting frames 1 are installed between the support columns 4, and the first planting frame 1 is welded to the support columns 4, and the first planting frame 1 is welded to the support columns 4. The bottom of the frame 1 is equipped with a second planting frame 2, the bottom of the second planting frame 2 is equipped with a third planting frame 3, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com