A polycrystalline diamond composite pick synthetic block and a method for synthesizing the same

A technology of polycrystalline diamond and composite picks, applied in the field of superhard material manufacturing, can solve the problems of low performance, unstable quality, and can not meet the synthesis needs of polycrystalline diamond composite picks, and achieves the effect of solving low performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

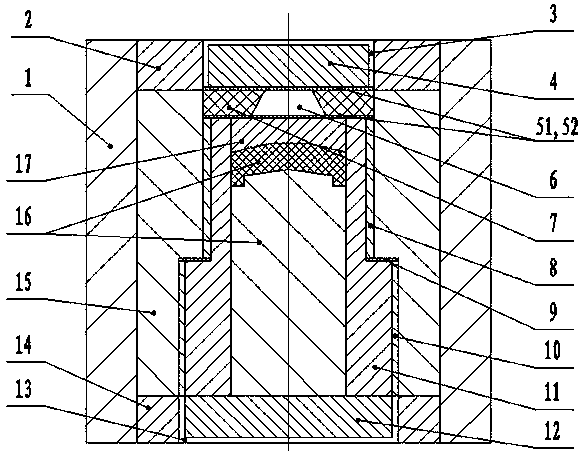

[0031] Such as figure 1 As shown, a polycrystalline diamond composite pick synthesis block includes a synthesis cavity for high temperature and high pressure sintering polycrystalline diamond composite pick blank 16, and the side walls of the synthesis cavity are sequentially provided with isolation layers from the inside to the outside 11. Heating layer, thermal insulation layer 15 and cylindrical shell, the top of the synthesis cavity is provided with a conductive layer and a conductive pressure transmission layer I sequentially from the inside and outside, and the bottom of the synthesis cavity is provided with a conductive pressure transmission layer II; Polycrystalline diamond composite pick blank 16 and isolation cap 17 are provided in the synthesis cavity, and the isolation cap is located on the top of polycrystalline diamond composite pick blank, and the heating layer is composed of heating tube 18, connecting gasket 9 and Composed of heating pipe II 10, the outer diam...

Embodiment 2

[0038] A kind of method utilizing synthetic block described in embodiment 1 to synthesize polycrystalline diamond composite pick, comprises the following steps:

[0039] 1) Put the pyrophyllite block 1, pyrophyllite ring I2 and pyrophyllite ring II14 in a vacuum sintering furnace, and vacuumize until the pressure in the furnace reaches 3×10 -3 Below Pa, heat to 380°C for 20h, and set aside;

[0040] 2) Place the polycrystalline diamond composite pick blank 16 in a vacuum sintering furnace, and roughly evacuate until the pressure in the furnace reaches 6×10 -2 Below Pa, heat to 180°C for 1 hour, then continue vacuuming and heat to 900°C until the pressure inside the furnace is stable at 3×10 -3 Below Pa, then stop vacuuming and fill the vacuum heating furnace with a mixed gas with a pressure of 150Mbar at 900°C to reduce the composite sheet blank for 5 hours, and then vacuumize to the furnace pressure of 3×10 -3 Below Pa; where:

[0041] The mixed gas is carbon dioxide and h...

Embodiment 3

[0046] A kind of method utilizing synthetic block described in embodiment 1 to synthesize polycrystalline diamond composite pick, comprises the following steps:

[0047] 1) Put the pyrophyllite block 1, pyrophyllite ring I2 and pyrophyllite ring II14 in a vacuum sintering furnace, and vacuumize until the pressure in the furnace reaches 3×10 -3 Below Pa, heat to 350°C for 25 hours, and set aside;

[0048] 2) Place the polycrystalline diamond composite pick blank 16 in a vacuum sintering furnace, and roughly evacuate until the pressure in the furnace reaches 6×10 -2 Below Pa, heat to 150°C for 1 hour, then continue vacuuming and heat to 950°C until the pressure inside the furnace is stable at 3×10 -3 Below Pa, then stop vacuuming and fill the vacuum heating furnace with a mixed gas with a pressure of 100Mbar at 950°C to reduce the composite sheet blank for 6 hours, and then vacuumize to the furnace pressure of 3×10 -3 Below Pa; where:

[0049] The mixed gas is carbon dioxide ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| percent by volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com