Precise detergent dosage control method and washing machine

A control method and detergent technology, applied in the field of methods and washing machines, can solve the problems of increased rinse times, detergent residue, foam increase, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

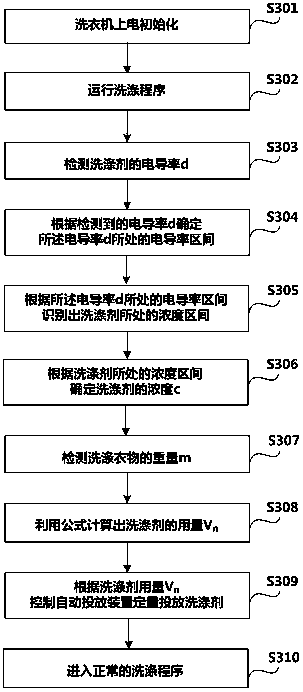

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1. In this embodiment, a conductivity detection method is used to obtain the concentration of detergent.

[0035] The concentration of detergent is reflected by the content of its active substances. Currently, there are two main methods for detecting the content of such active substances: optical sensor detection method and chemical reagent detection method. Among them, the optical sensor detection method has a high sensor cost and a complicated structure. If it is applied to a washing machine, it will not only complicate the hardware structure design of the washing machine, but also significantly increase the cost of the washing machine. However, the chemical reagent detection method requires offline detection, consumes reagents, and cannot achieve concentration distinction online, so it is not suitable for application in washing machine products.

[0036] In order to meet the application requirements of the washing machine, this embodiment uses the conducti...

Embodiment 2

[0100] In the second embodiment, the detergent concentration is obtained by manually inputting the detergent concentration parameter.

[0101] see Figure 5 , Image 6 In this embodiment, a detergent box 22, an automatic feeding device 25, a weight detection device 27, a man-machine interface 29 and a control module 28 are provided in the washing machine. Wherein, the detergent box 22 is used for storing a certain capacity of detergent 23, and its storage capacity can meet the demand of detergent dosage for multiple washing procedures. An automatic dispensing device 25 is installed on the detergent box 22 for quantitatively extracting and dispensing the detergent 23 stored in the detergent box 22 . Similarly, the automatic delivery device 25 can also be designed in various ways such as Venturi tube negative pressure quantitative extraction mode, quantitative pump automatic extraction mode, and the like. The detergent 23 quantitatively extracted by the automatic dispensing d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com