Phosphorus-free rust-proof metal cleaning agent and preparation method thereof

A metal cleaning agent and cleaning aid technology, applied in the field of industrial cleaning, can solve problems such as low cleaning effect, endangering the environment, people's health, and rust on the metal surface, and achieve excellent decontamination ability, low price, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

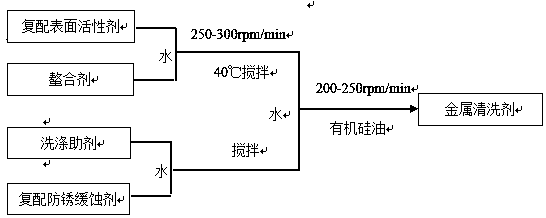

Image

Examples

Embodiment 1

[0018] 15 parts of nonionic surfactant fatty alcohol polyoxyethylene ether, 10 parts of coconut oil fatty acid diethanolamide, 9 parts of anionic surfactant sodium dodecylbenzenesulfonate, 5 parts of sodium citrate, 5 parts of sodium silicate, 10 parts of sodium metasilicate, 3 parts of antirust and corrosion inhibitor, 1 part of silicone oil, 90 parts of water.

Embodiment 2

[0020] 13 parts of nonionic surfactant fatty alcohol polyoxyethylene ether, 12 parts of coconut oil fatty acid diethanolamide, 10 parts of anionic surfactant sodium dodecylbenzenesulfonate, 6 parts of sodium citrate, 4 parts of sodium silicate, 9 parts of sodium metasilicate, 4 parts of antirust and corrosion inhibitor, 2 parts of silicone oil, 100 parts of water.

Embodiment 3

[0022] 14 parts of nonionic surfactant fatty alcohol polyoxyethylene ether, 11 parts of coconut oil fatty acid diethanolamide, 8 parts of anionic surfactant sodium dodecylbenzenesulfonate, 6 parts of sodium citrate, 4 parts of sodium silicate, 8 parts of sodium metasilicate, 4 parts of antirust and corrosion inhibitor, 1 part of silicone oil, 100 parts of water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com