Metal surface local region precise corrosion method

A local area, local corrosion technology, applied in the field of detection, can solve problems such as unpublished, and achieve the effect of precise control of corrosion depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

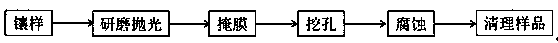

[0091] Such as figure 1 As shown in the process flow, a method for precise etching of a local area of a metal surface includes the following steps:

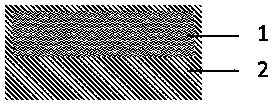

[0092] 1) Mount the metal zirconium sample, the zirconium size is 5mm*5mm*1mm, the mounting material is epoxy resin, the overall diameter after mounting is 15mm, and the thickness is 5mm, such as figure 2 ;

[0093] 2) Grinding and polishing the mounted sample 5mm*5mm as the surface to be corroded, exposing the zirconium smooth surface; grinding and polishing using 500#, 800#, 1200#, 2400# different particle sizes of sandpaper from coarse to fine, Polish with a polishing cloth to reveal a zirconium finish such as image 3 ;

[0094] 3) Mask the exposed zirconium smooth surface. Specifically, use 502 glue for masking. The thickness of the mask is about 1mm. The mask completely covers the exposed smooth surface. There are no air bubbles or pores between the membranes, such as Figure 4 , the specific masking method is: appl...

Embodiment 2

[0099] Such as figure 1 As shown in the process flow, a method for precise etching of a local area of a metal surface includes the following steps:

[0100] 1) Mount the metal zirconium sample, the zirconium size is 5mm*5mm*1mm, the mounting material is epoxy resin, the overall diameter after mounting is 15mm, and the thickness is 5mm, such as figure 2 ;

[0101] 2) Grinding and polishing the mounted sample 5mm*5mm as the surface to be corroded, exposing the zirconium smooth surface; grinding and polishing using 500#, 800#, 1200#, 2400# different particle sizes of sandpaper from coarse to fine, Polish with a polishing cloth to reveal a zirconium finish such as image 3 ;

[0102] 3) Mask the exposed zirconium smooth surface. Specifically, paraffin wax is used for masking. The thickness of the mask is about 1mm. The mask completely covers the exposed smooth surface. The zirconium smooth surface is in good contact with the mask, and the smooth surface and the mask There a...

Embodiment 3

[0107] Such as figure 1 As shown in the process flow, a method for precise etching of a local area of a metal surface includes the following steps:

[0108] 1) Mount the metal zirconium sample, the zirconium size is 5mm*5mm*1mm, the mounting material is epoxy resin, the overall diameter after mounting is 15mm, and the thickness is 5mm, such as figure 2 ;

[0109] 2) Grinding and polishing the mounted sample 5mm*5mm as the surface to be corroded, exposing the zirconium smooth surface; grinding and polishing using 500#, 800#, 1200#, 2400# different particle sizes of sandpaper from coarse to fine, Polish with a polishing cloth to reveal a zirconium finish such as image 3 ;

[0110] 3) Mask the exposed zirconium smooth surface. Specifically, hot melt adhesive is used for masking. The thickness of the mask is about 1mm. The mask completely covers the exposed smooth surface. The zirconium smooth surface is in good contact with the mask, and the smooth surface No air bubbles ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com