6063 aluminum alloy material for solar energy aluminum frame production

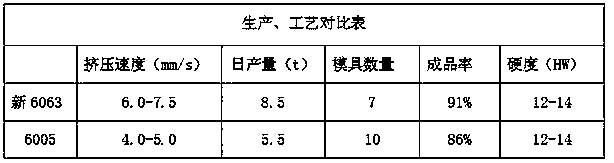

A technology of aluminum alloy material and aluminum frame, applied in the field of 6063 aluminum alloy material, can solve the problems of slow extrusion and discharge rate of 6005 alloy, reduce production efficiency, increase production cost, etc., to improve labor efficiency, save production cost, The effect of optimizing profile properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

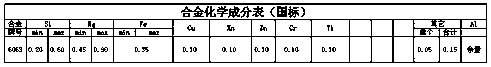

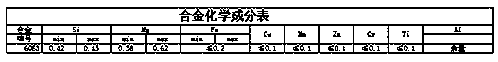

[0019] A 6063 aluminum alloy material for the production of solar aluminum frames, the composition and weight percentage of the 6063 aluminum alloy are: Si: 0.42%-0.45%, Mg: 0.58%-0.62%, Fe: 0-0.20%, Cu : 0-0.10%, Mn: 0-0.10%, Zn: 0-0.10%, Cr: 0-0.10%, Ti: 0-0.10%, Al: balance, the sum of the percentages of each component is 100%.

[0020] The present invention mainly reduces the range of alloys of Mg and Si, and at the same time adjusts the ratio of Mg and Si.

[0021] In the Mg2Si compound, the mass ratio of magnesium to silicon is 1.38:1.

[0022] Alloy production process optimization of the present invention is as follows:

[0023] S1. Ingredients: carry out alloy proportioning according to the above ingredients;

[0024] S2. Smelting and pouring: casting the aluminum alloy with the above alloy ratio;

[0025] S3. Extrusion molding: set the proper temperature of the mold heating furnace to ensure that the extrusion outlet temperature is within the range of 520-540°C;

...

Embodiment 2

[0033] A 6063 aluminum alloy material used for the production of solar aluminum frames, the composition and weight percentage of the 6063 aluminum alloy are: Si: 0.42%-0.45%, Mg: 0.58%-0.62%, Fe: 0.10%-0.20%, Cu: 0-0.05%, Mn: 0-0.10%, Zn: 0-0.10%, Cr: 0-0.05%, Ti: 0-0.10%, Al: balance, the sum of the percentages of each component is 100%.

[0034] In the Mg2Si compound, the mass ratio of magnesium to silicon is 1.38:1

[0035] The production process of the present embodiment is the same as that of the first embodiment

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com