Gypsum based vitrified brick binder and preparation method thereof

The technology of base vitrified brick and adhesive is applied in the field of vitrified brick adhesive, which can solve the problems of weak mechanical anchoring, insufficient filling of pores on the back of the adhesive and vitrified brick, and decreased bonding strength, etc. Achieve the effect of expanding resource utilization, good construction performance and excellent adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

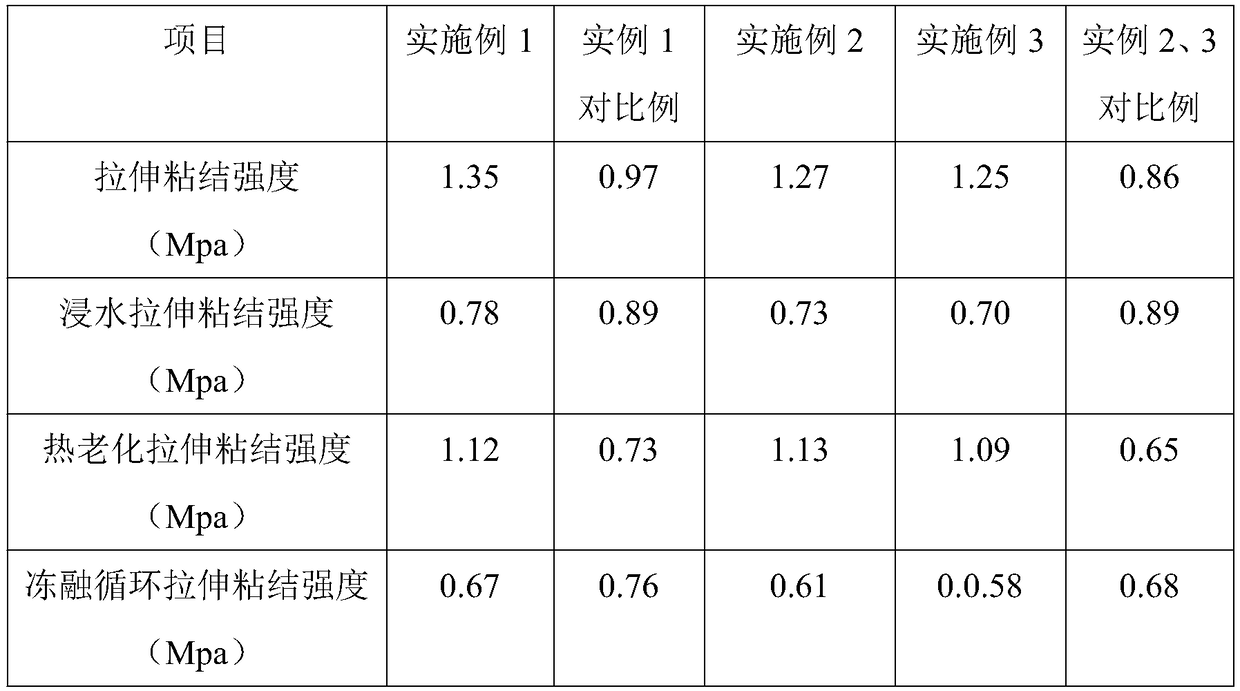

Examples

Embodiment 1

[0030] A gypsum-based vitrified tile adhesive, which is composed of the following raw materials: α gypsum: 400 parts, 70-120 mesh grade sand: 600 parts, water retaining agent: 3 parts, redispersible latex powder: 12 parts, retarding Agent: 0.2 parts, 5 parts of wood fiber, 5 parts of water repellent, 1 part of starch ether, calculated in parts by weight.

[0031] Among them, the graded sand is dried and washed river sand; the water retaining agent is 60000Mpas hydroxypropyl methylcellulose ether. The redispersible latex powder is vinyl chloride / ethylene / vinyl laurate lipid latex powder; the retarder is amino acid gypsum retarder; the water repellent is silicone powder water repellent.

[0032] A preparation method of a gypsum-based vitrified tile adhesive can be prepared by fully mixing the above raw materials in parts by weight.

[0033] A method of using a gypsum-based vitrified brick adhesive (thin paste method): first, weigh 1000 parts of the above-mentioned adhesive and ...

Embodiment 2

[0035] A gypsum-based vitrified tile adhesive, which is composed of the following raw materials: α gypsum: 400 parts, 40-70 mesh grade sand: 600 parts, water retaining agent: 1.5 parts, redispersible latex powder: 18 parts, retarding Agent: 0.2 parts, 5 parts of wood fiber, 5 parts of water repellent, 0.8 parts of starch ether.

[0036] Among them, the graded sand is dried and washed river sand; the water retaining agent is 60000Mpas hydroxypropyl methylcellulose ether. The redispersible latex powder is vinyl chloride / ethylene / vinyl laurate lipid latex powder; the retarder is an amino acid gypsum retarder; and the water-repellent is a silicone powder water-repellent.

[0037] A preparation method of a gypsum-based vitrified tile adhesive can be prepared by fully mixing the above raw materials in parts by weight.

[0038] A method for using a gypsum-based vitrified adhesive (thick pasting method): Weigh 1000 parts of adhesive and 220 parts of water according to parts by weight...

Embodiment 3

[0040] A gypsum-based vitrified tile adhesive, which is composed of the following raw materials: α gypsum: 380 parts, 40-70 mesh grade sand: 620 parts, water retaining agent: 1.5 parts, redispersible latex powder: 15 parts, retarding Agent: 0.15 parts, 6 parts of wood fiber, 6 parts of water-repellent agent, 0.8 part of starch ether.

[0041] Among them, the graded sand is dried and washed river sand; the water retention agent is 60000Mpas hydroxypropyl methylcellulose ether; the redispersible latex powder is vinyl chloride / ethylene / vinyl laurate lipid latex powder; the retarder is amino acid Gypsum retarder; the water repellent is organic silicon powder water repellent.

[0042] A preparation method of a gypsum-based vitrified tile adhesive can be prepared by fully mixing the above raw materials in parts by weight.

[0043] A method of using a gypsum-based vitrified adhesive (thick paste method): weigh 1000 parts of adhesive and 220 parts of water according to parts by weigh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com