Blowtorch and mandrel manufacturing method

A blowtorch and mandrel technology, applied in the direction of manufacturing tools, glass manufacturing equipment, glass deposition furnace, etc., can solve the problems affecting the transmission speed and quality, the deviation of optical parameters exceeds the standard, and affect the optical performance of single-mode optical fiber, etc., so as to improve the deposition rate , Improve the effect of refractive index distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Before describing the present invention, it should be noted that the present invention is not limited to the specific embodiments described below. Those skilled in the art can understand that without departing from the spirit of the claims of the present invention, changes and modifications can be made to the specific embodiments described below.

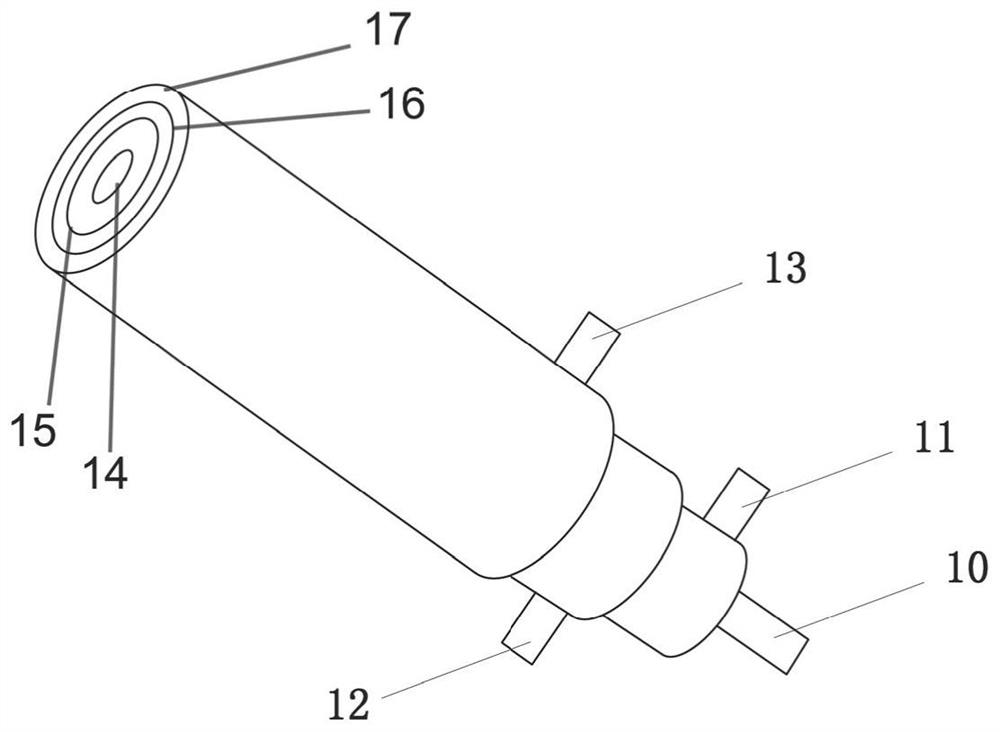

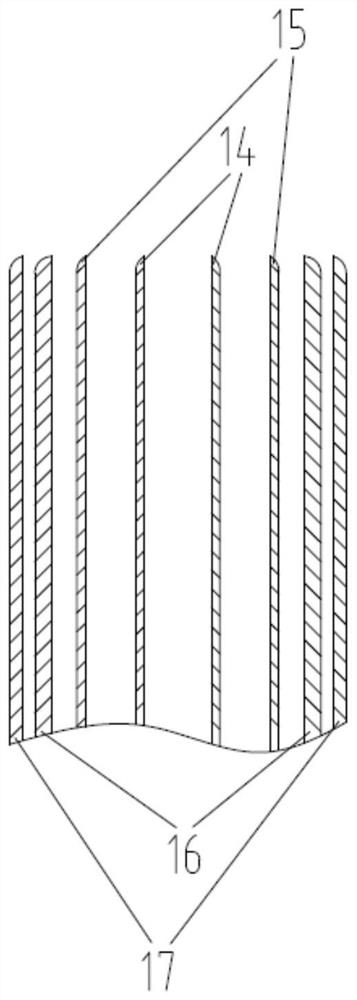

[0045] figure 1 and figure 2 It is a schematic diagram and a cross-sectional view of a traditional four-layer blowtorch in the VAD mandrel deposition process, respectively. exist figure 1 and figure 2 Among them, a conventional four-layer blowtorch is formed by a central tube 14 and three outer tubes 15, 16, 17 surrounding the central tube, which are arranged sequentially from the inside to the outside. The central tube 14 and the three outer tubes 15, 16, 17 are all provided with feeding ports, namely including the first feeding port 10, the second feeding port 11, the third feeding port 12 and the fourth feeding port ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com