Flowing electrode electro-adsorption water purification method with low wastewater rate and water purifier

A flow electrode and electro-adsorption technology, applied in the field of water treatment, can solve the problems of troublesome system operation, uncontinuous desalination process, low mineral ion content, etc., and achieve the effect of high recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Tap water first needs to be coarsely filtered through PP cotton and activated carbon to remove particulate matter, residual chlorine, and heavy metals to obtain pretreated tap water. The mobile electrode slurry is formed by mixing 200 mesh activated carbon powder and acetylene black in tap water, m (activated carbon): m (acetylene black) = 70%: 30%, and the solid-liquid ratio of the mobile electrode slurry is m (solid): m(water)=2:8, the volume of the flowing electrode slurry in the experiment is 600mL.

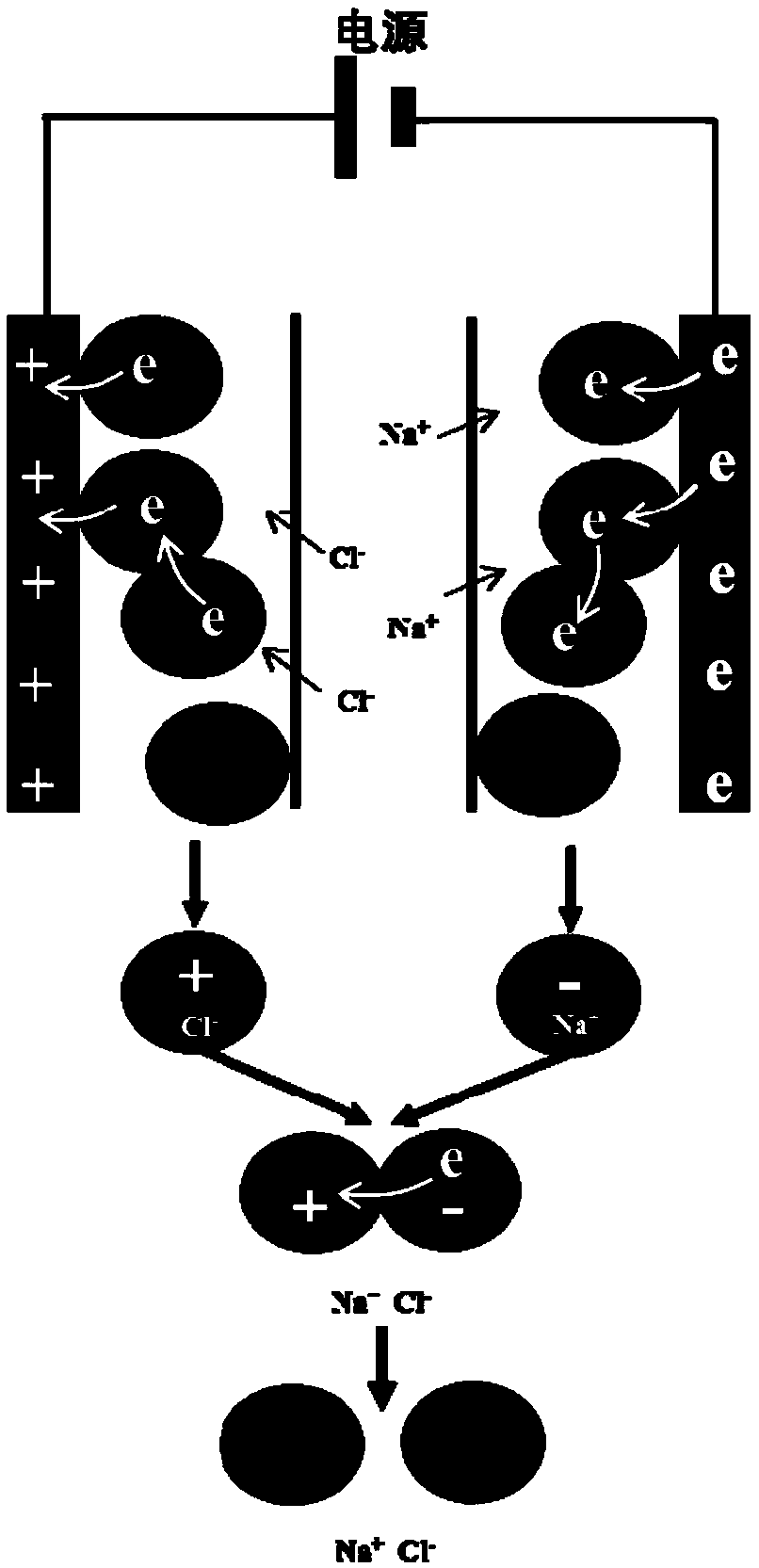

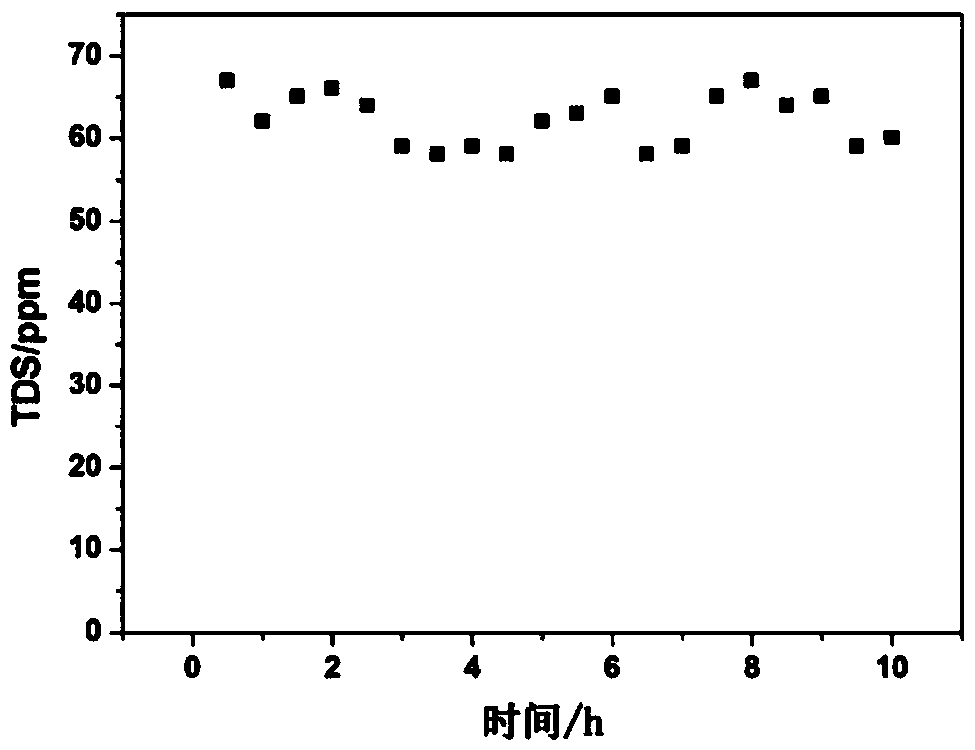

[0050] according to figure 2 The working principle of the middle flow electrode electrosorption type water purifier is tested: the number of membrane pairs of anion and cation selective exchange membranes in the flow electrode electrosorption module is 20 pairs, and the number of membrane pairs of anion and cation selective exchange membranes in the electrodialysis desorption module is Quantity is 4 pairs. The pretreated tap water enters the flow electrode electroso...

Embodiment 2

[0056] Tap water first needs to be coarsely filtered through PP cotton and activated carbon to remove particulate matter, residual chlorine, and heavy metals to obtain pretreated tap water. The mobile electrode slurry is formed by mixing 230 mesh activated carbon powder and acetylene black in tap water, m (activated carbon): m (acetylene black) = 65%: 35%, and the solid-liquid ratio of the mobile electrode slurry is m (solid): m(water)=3:7, the volume of the flowing electrode slurry in the experiment is 600mL.

[0057] according to figure 2 The working principle of the middle flow electrode electrosorption type water purifier is tested: the number of membrane pairs of anion and cation selective exchange membranes in the flow electrode electrosorption module is 30 pairs, and the number of membrane pairs of anion and cation selective exchange membranes in the electrodialysis desorption module is Quantity is 6 pairs. The pretreated tap water enters the flow electrode electroso...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com