Back self-storage multi-stage solar still

A technology of solar distiller and solar heat collector, which is applied in seawater treatment, water/sewage treatment, general water supply conservation, etc., can solve the problems of low energy efficiency, high investment cost, and large heat capacity of seawater to be evaporated, and achieve structural Simple, compact overall design, good economy and practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below with reference to the accompanying drawings and embodiments.

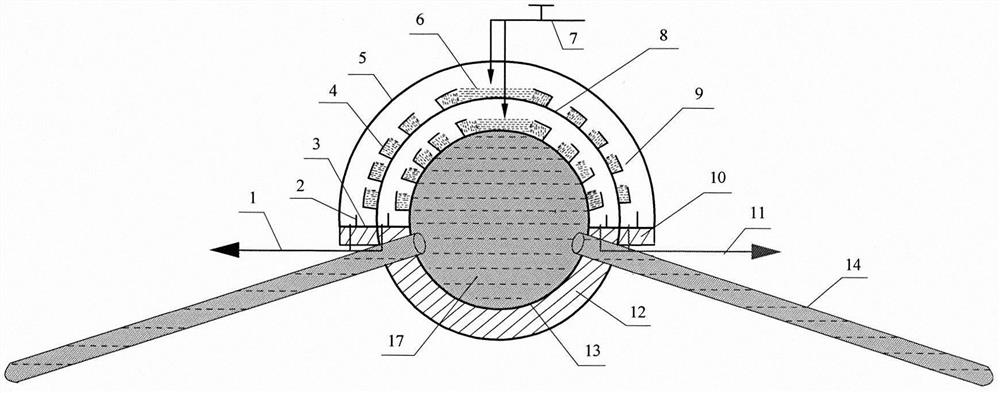

[0018] like figure 1 As shown, the present invention provides a back self-storage multi-stage solar distiller, which utilizes solar heat storage to heat seawater to generate fresh water. The multi-stage solar distiller adopts a coaxial arrangement, wherein the hot water storage barrel (13) is a horizontal cylindrical shape and is located in the center, and the evaporation and condensation walls (8) are semi-cylindrical and distributed on the outer peripheral side of the hot water storage barrel (13). . A vacuum tube solar heat collector (14) is arranged on the lower semi-cylindrical surface of the hot water storage tank (13). Sunlight irradiates on the vacuum tube collector (14), the heat storage fresh water (15) stores thermal energy, and heats the seawater (6) distributed in the salt water tank (4) outside the wall of the hot water storage barrel (1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com