Quick and automatic chalk film-pasting robot assembly line

A robot and assembly line technology, applied in the direction of external support, transport packaging, tubular objects, etc., can solve the problems of affecting the surrounding environment, shedding chalk dust, impact, etc., to achieve high feeding efficiency and reduce labor costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

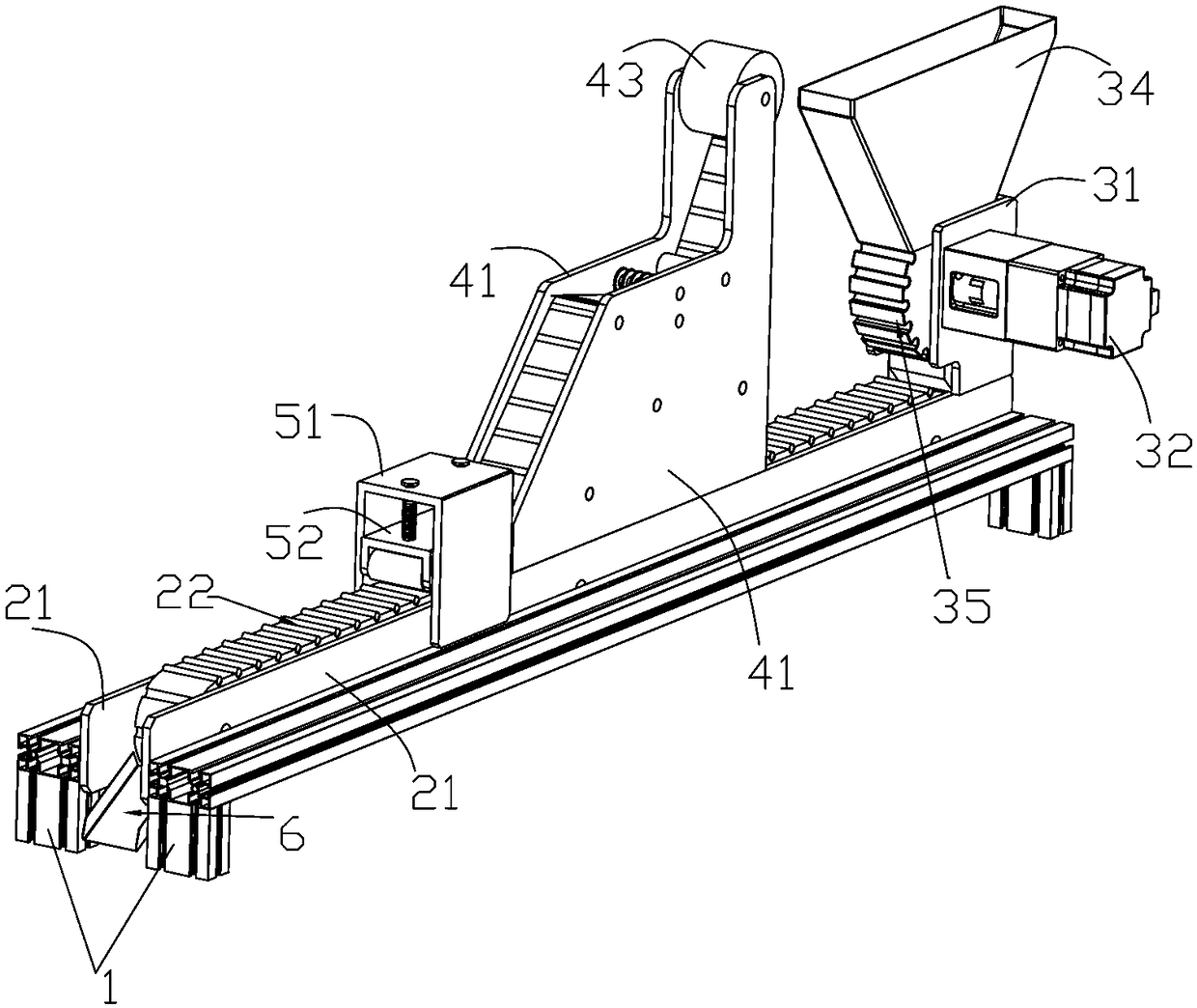

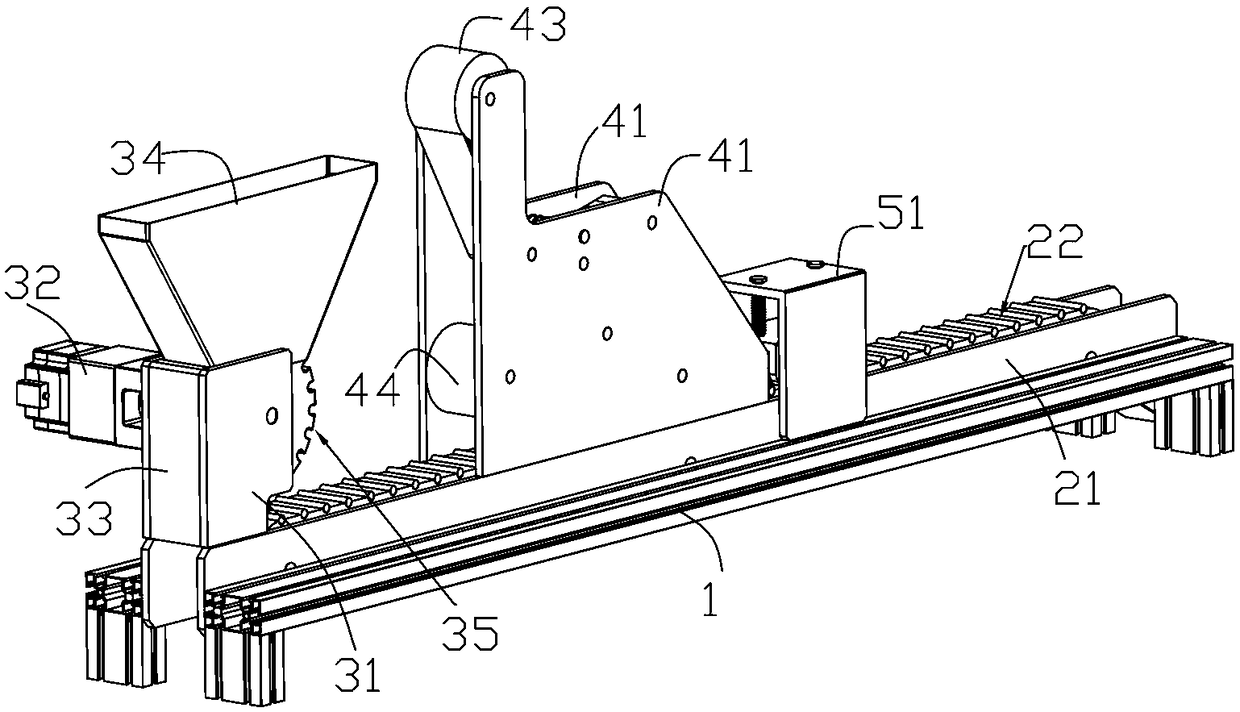

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, and the implementation scope of the present invention is not limited thereto.

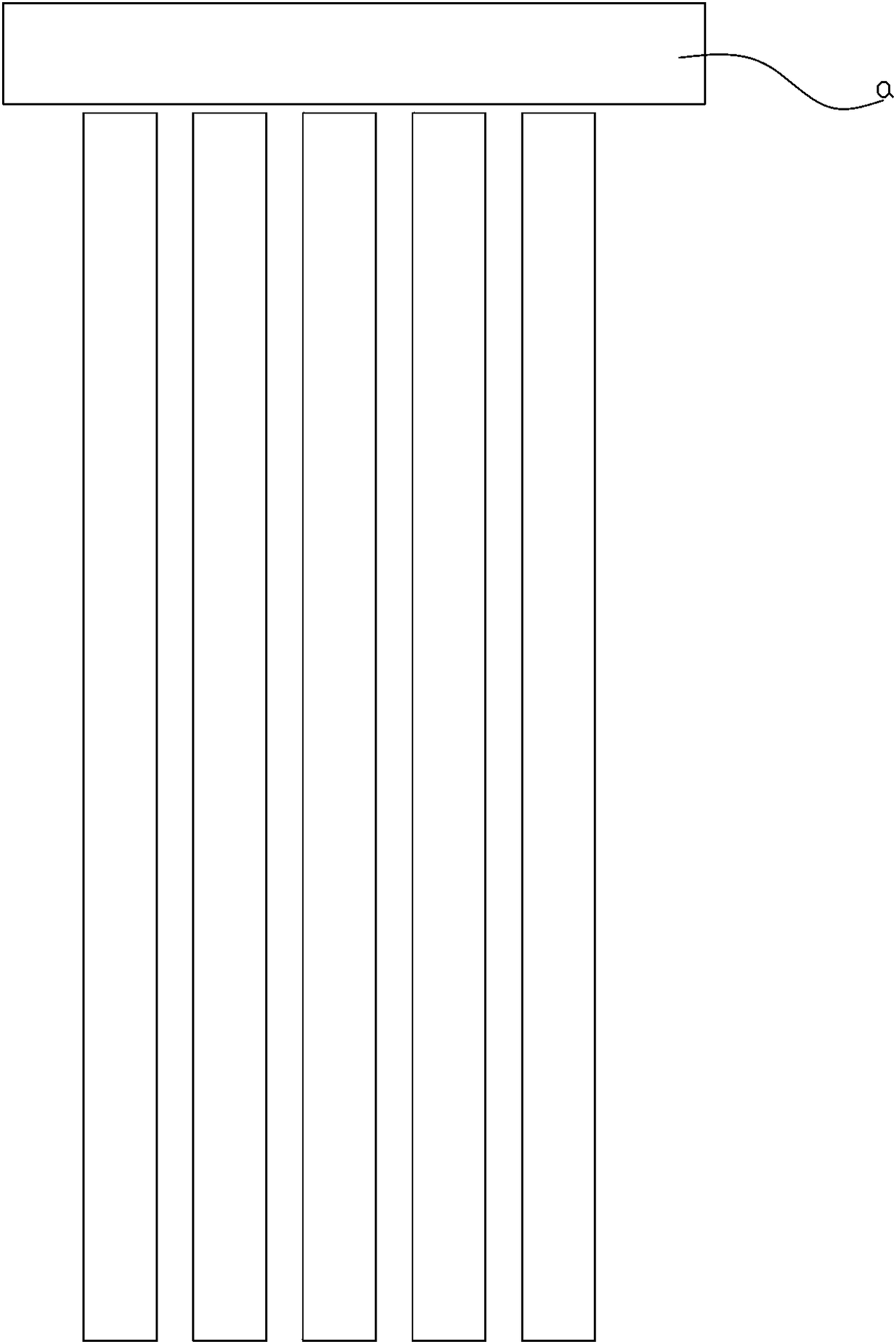

[0030] Such as Figure 1 to Figure 13 As shown, a fast chalk automatic film-attaching robot assembly line described in this embodiment includes a plurality of film-attaching mechanisms arranged side by side, and a conveyor belt is provided on one side of the multiple film-attaching mechanisms.

[0031] The film pasting mechanism includes two racks 1 arranged at intervals, a chalk feeding mechanism, a chalk distributing mechanism, a sticker conveying mechanism and a pressing mechanism, the sticker conveying mechanism is located between the chalk distributing mechanism and the compacting mechanism, and the pressing The tightening mechanism is set close to the sticker conveying mechanism;

[0032] Described chalk feeding mechanism comprises two feeding connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com