Intelligent molding machine for pneumatic box and molding technology thereof

A forming machine and box technology, which is applied in box making operations, decorative art, container manufacturing machinery, etc., can solve the problems that the brush roller cannot be fine-tuned and takes a long time, so as to save manual operation, reduce preparation hours, and avoid The effect of interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below in conjunction with accompanying drawing and embodiment of description, specific embodiment of the present invention is described in further detail:

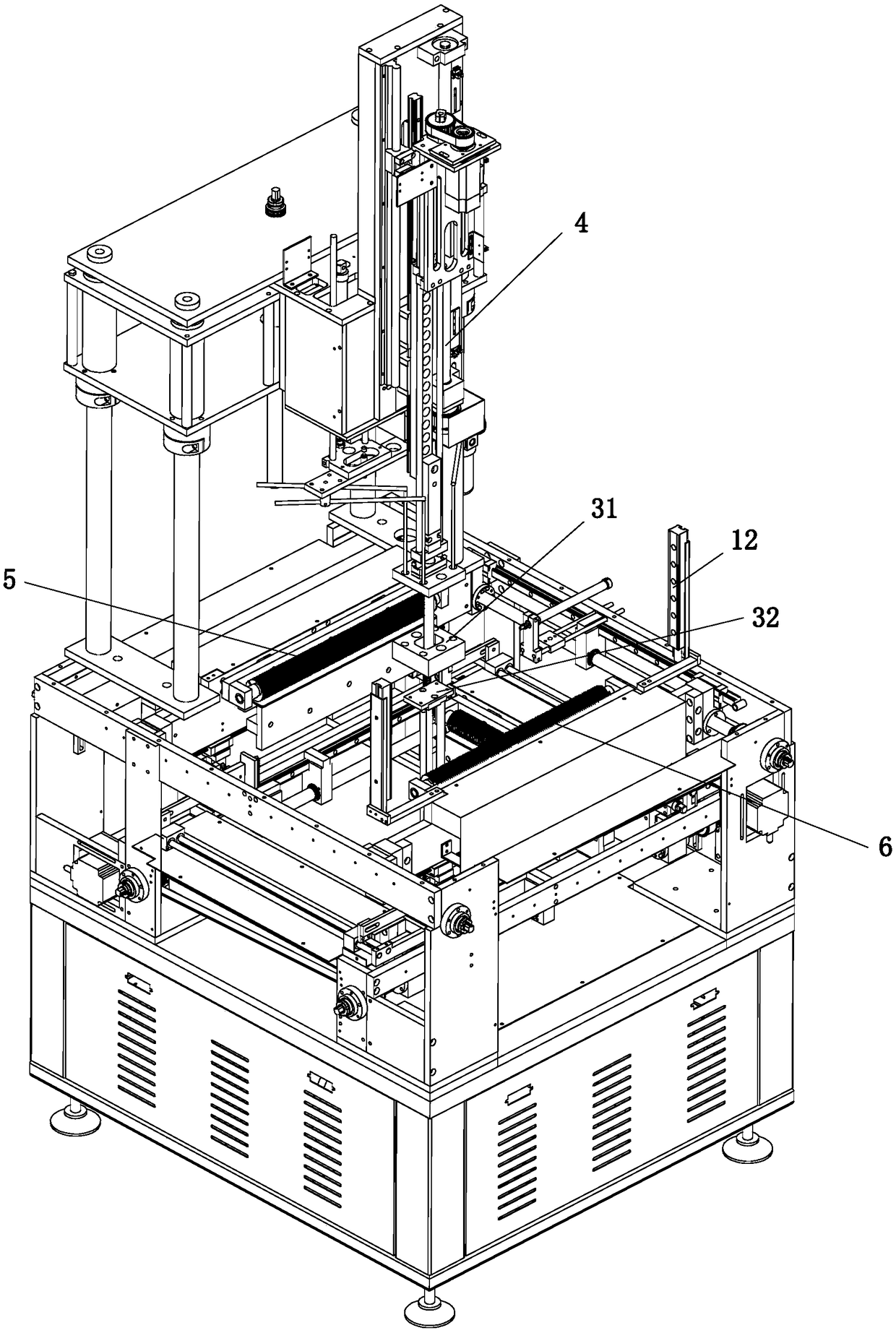

[0033] refer to Figure 1 to Figure 9 The shown intelligent pneumatic box forming machine includes a pressing mechanism 1 for positioning the tissue, a folding device 2 for folding the tissue and a control device. The pressing mechanism 1 includes a box mold 3 and a In order to drive the lifting mechanism 4 of the box mold 3 to lift, the folding device 2 includes a first folding mechanism for folding the long side of the facial tissue, and a first folding mechanism for folding the short side of the facial tissue. The second folding mechanism and ear folding mechanism, the box mold 3 is arranged in the center of the folding device 2, the lifting mechanism 4 is arranged directly above the box mold 3, and the first folding mechanism includes useful The first folding assembly 5, the second folding assembly 6 and the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com