Device for removing bamboo green on surface of bamboo tube

A bamboo tube and bamboo green technology, which is applied in the field of tools and equipment for removing bamboo green on the surface of bamboo tubes, can solve the problems of low processing efficiency and high labor intensity of operators, and achieve the effect of good surface quality, simple structure and small impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

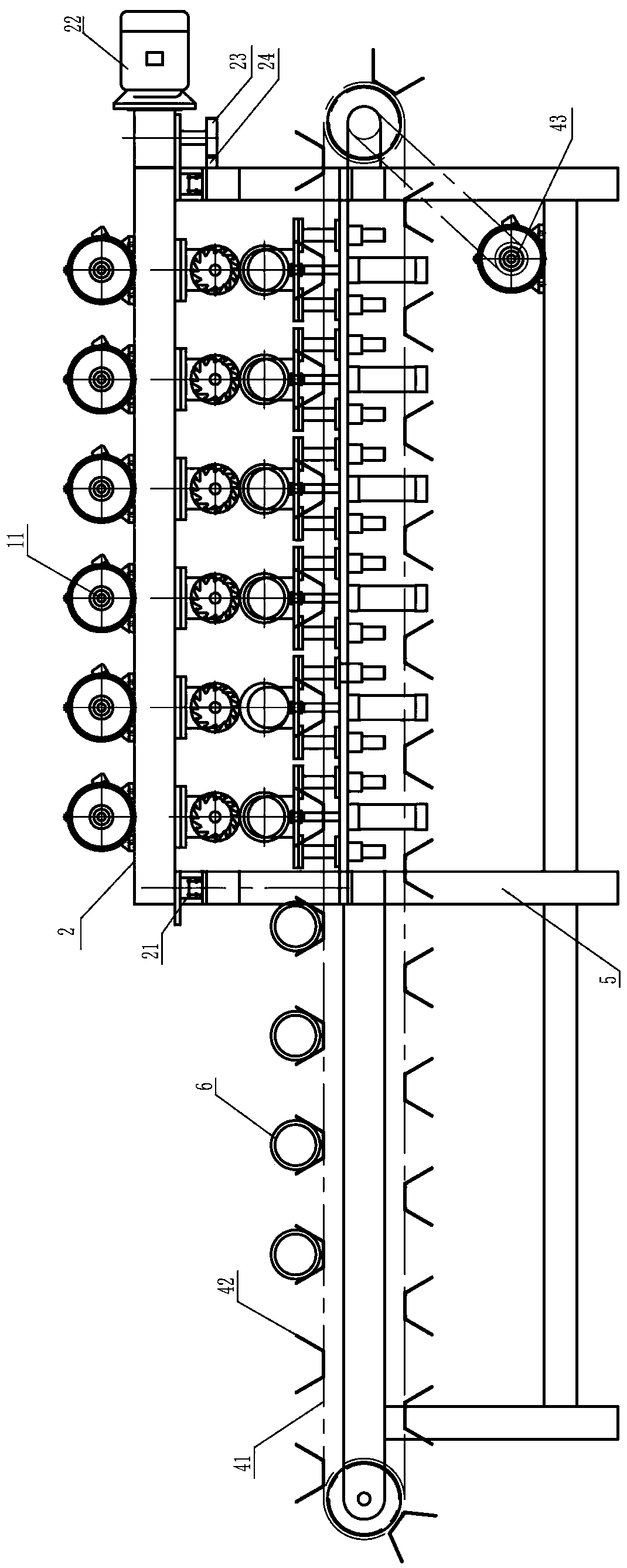

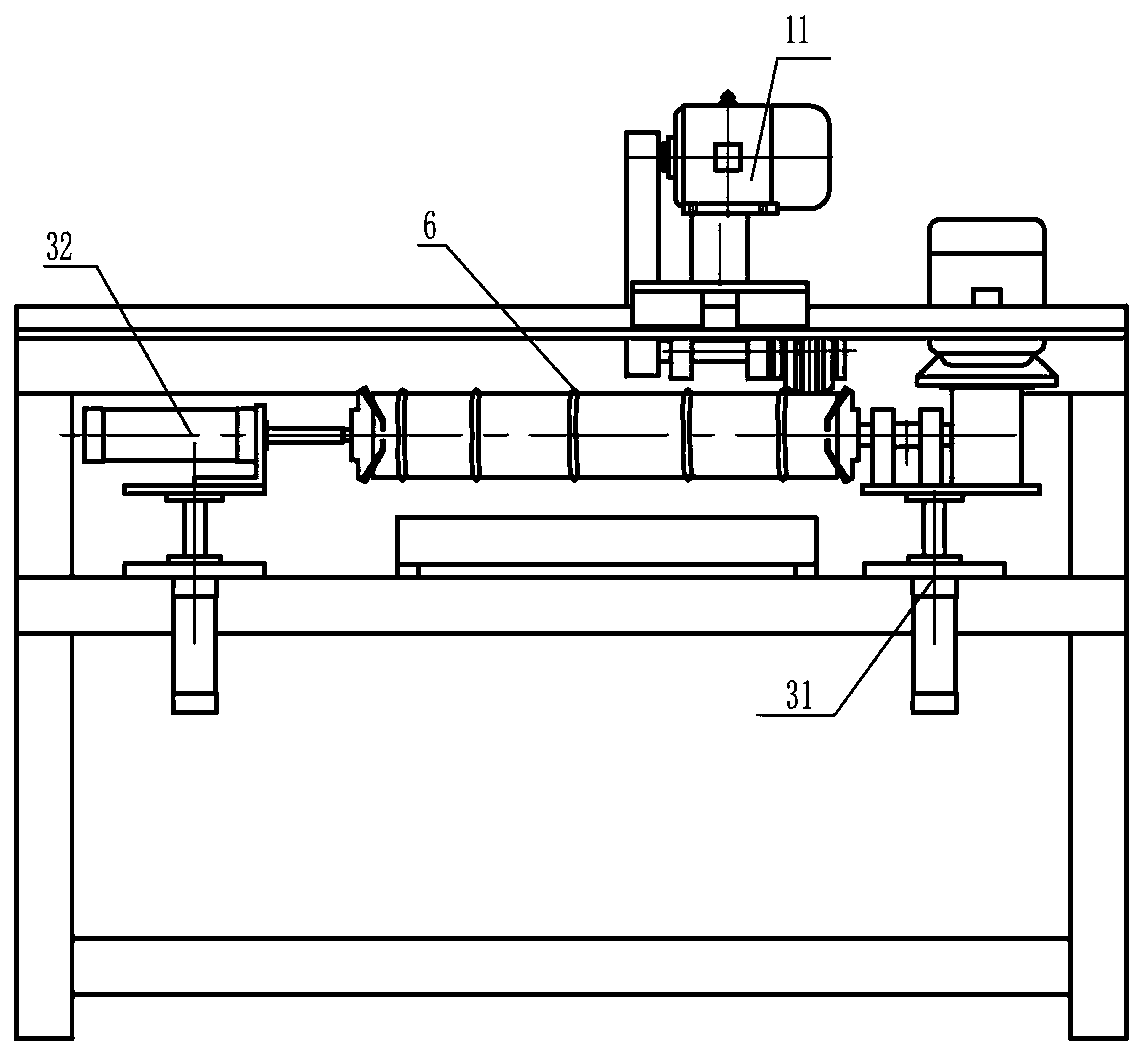

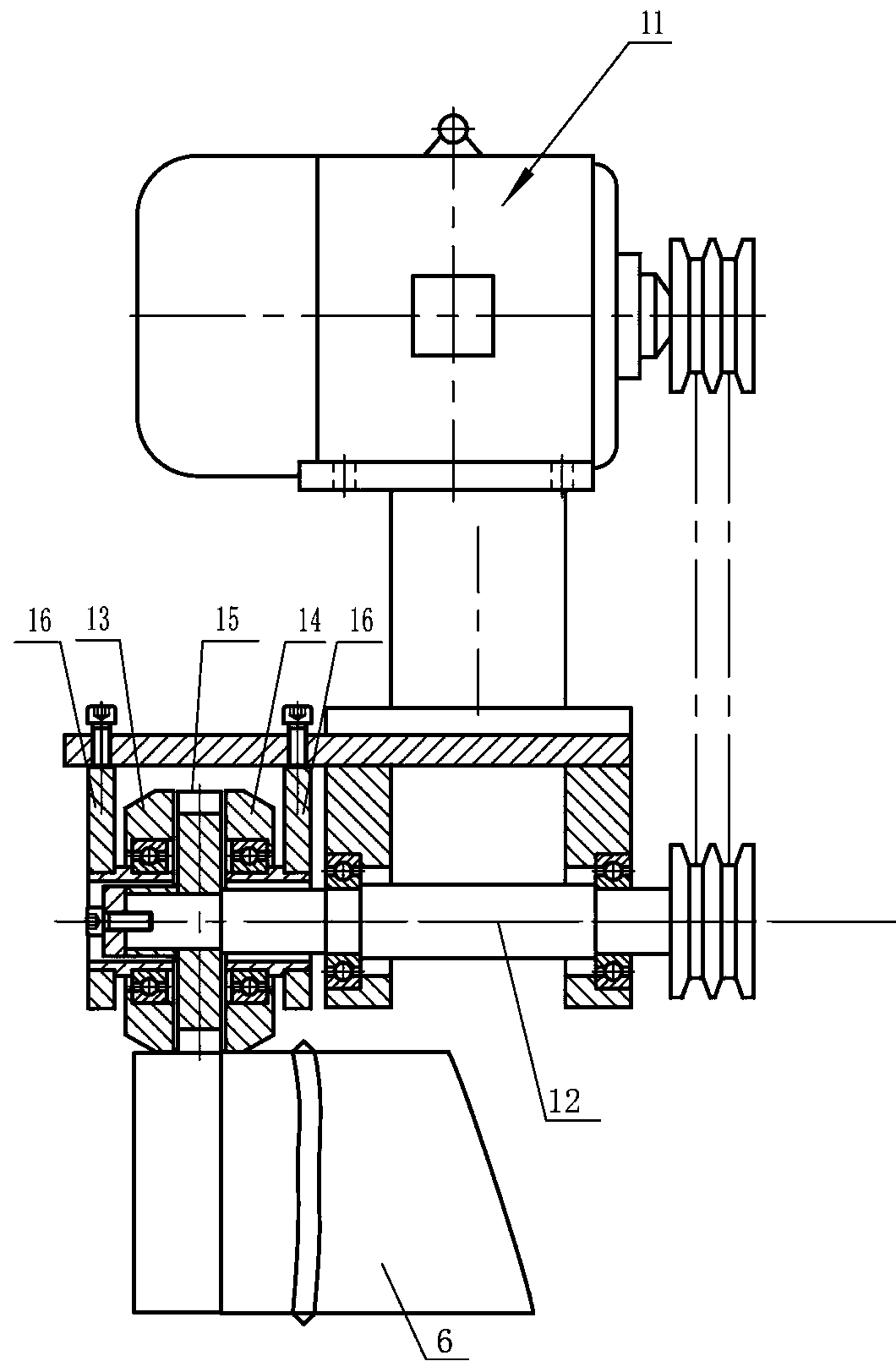

[0041] The principle and structural composition of the blue removal equipment according to the present invention will be further described below in conjunction with the accompanying drawings by way of example.

[0042] refer to figure 1 , 2 , this example shows a six-axis bamboo tube degreening equipment, the front, back, left, and right sides of the equipment are respectively figure 1 shown on the right, figure 1 shown on the left, figure 2 shown on the left, figure 2 shown on the right. When the equipment is running, the bamboo tube is removed from the figure 1 The left side shown conveys to the right side. In this document, the front-to-back direction of the device is taken as portrait, and the left-to-right direction is taken as landscape.

[0043] The frame 5 is a frame structure, and the clamping position and the processing position are designed in the front half of the frame, and the loading position is designed in the rear half of the frame. The front half in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com