Preparation method of adsorption material based on modified konjac glucomannan

A konjac glucomannan and adsorption material technology, applied in the field of preparation of glucomannan derivatives, can solve the problems of small ion adsorption selectivity, weak coordination ability, high viscosity, etc., and achieve many adsorption sites and production And the effect of low cost and enhanced complexing ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

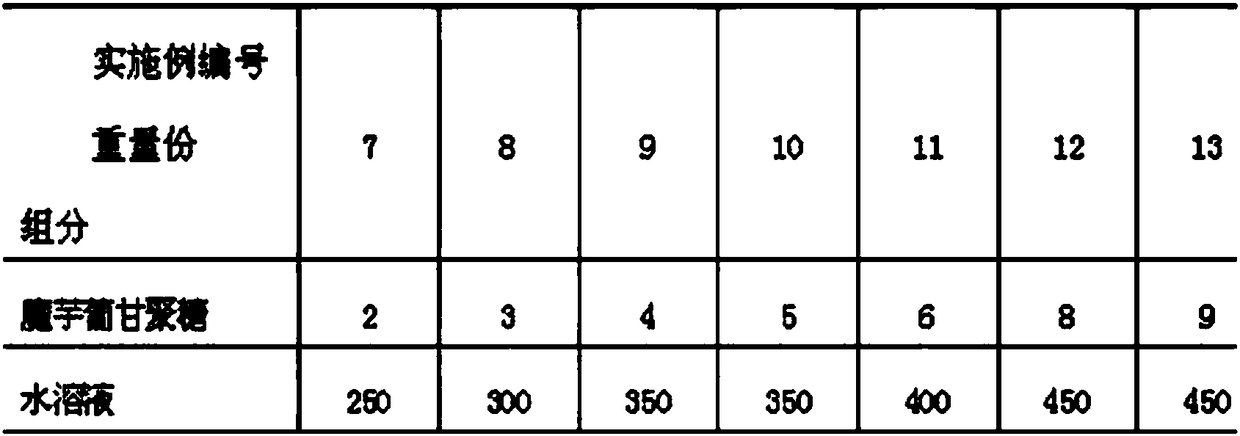

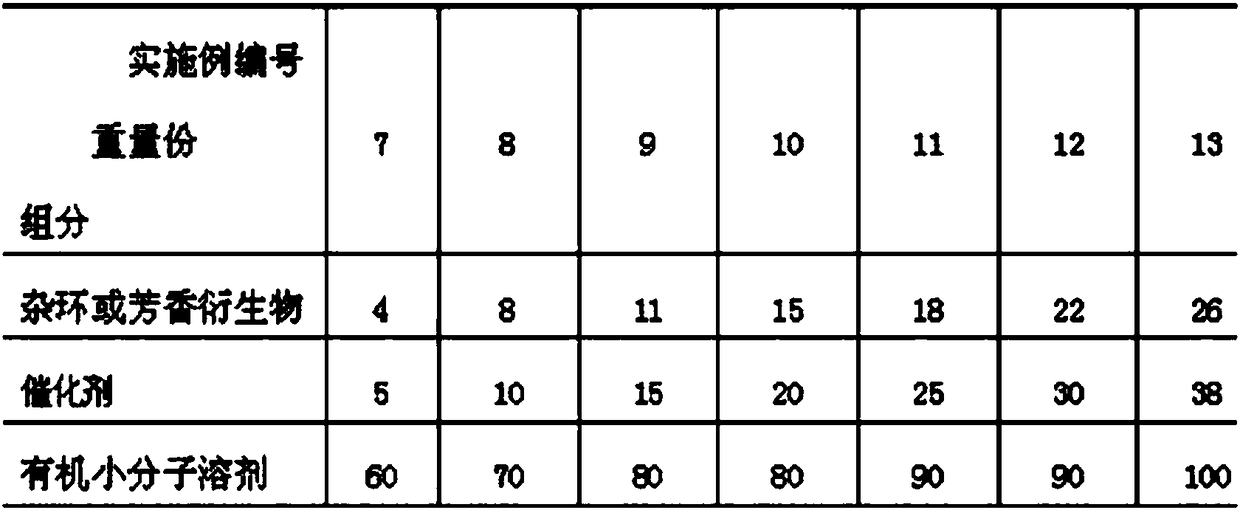

Examples

Embodiment 1

[0026] A preparation method of an adsorption material based on modified konjac glucomannan, comprising the following steps:

[0027] 5 parts of konjac fine powder were swelled in 50% acetic acid aqueous solution at 40°C for 12 hours, then vacuum filtered, then washed off residual moisture with anhydrous acetic acid (washed at least three times), and added to 100 parts of phthalic anhydride dissolved in 15 parts In the acetic acid solution, when the reaction temperature was adjusted to 100°C, 20 parts of anhydrous pyridine was quickly added as a catalyst. After reacting for 5 hours, the product was precipitated with 50% ethanol aqueous solution, vacuum filtered after complete precipitation, and the remaining water was washed with ethanol (at least three times). The final product was obtained after the product was dried in a blast oven at 50° C. for 20 hours.

Embodiment 2

[0029] A preparation method of an adsorption material based on modified konjac glucomannan, comprising the following steps:

[0030]5 parts of konjac fine powder were swelled in 50% ethanol aqueous solution at 25°C for 24 hours, then vacuum filtered, then washed off residual moisture with absolute ethanol (washed at least three times), and added to 100 parts of phthalic anhydride dissolved in 15 parts In the ethanol solution of , when the reaction temperature was adjusted to 100°C, 20 parts of anhydrous pyridine was quickly added as a catalyst. After reacting for 8 hours, the product was precipitated with 50% ethanol aqueous solution, vacuum filtered after complete precipitation, and the remaining water was washed with ethanol (at least three times). The final product was obtained after the product was dried in a blast oven at 50° C. for 20 hours.

Embodiment 3

[0032] A preparation method of an adsorption material based on modified konjac glucomannan, comprising the following steps:

[0033] 5 parts of konjac fine powder were swelled in 50% triethylamine aqueous solution at 50°C for 4 hours, then vacuum filtered, and then washed off residual moisture with anhydrous acetic acid (washed at least three times), and added to the solution containing 15 parts of o-nitrate In 100 parts of acetic acid solution of base phthalic anhydride, when the reaction temperature was adjusted to 100°C, 20 parts of 0.1 sulfuric acid (the solvent was anhydrous acetic acid) was quickly added as a catalyst. After reacting for 8 hours, the product was precipitated with 50% ethanol aqueous solution, vacuum filtered after complete precipitation, and the remaining water was washed with ethanol (at least three times). The final product was obtained after the product was dried in a blast oven at 50° C. for 20 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com