Method for detecting reaction performance of furnace slag

A technology of reaction performance and slag, which is applied in the field of metallurgy, can solve the problems of large influence of subjective factors and inaccurate detection results, and achieve the effects of easy operation, simplicity, accuracy and detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

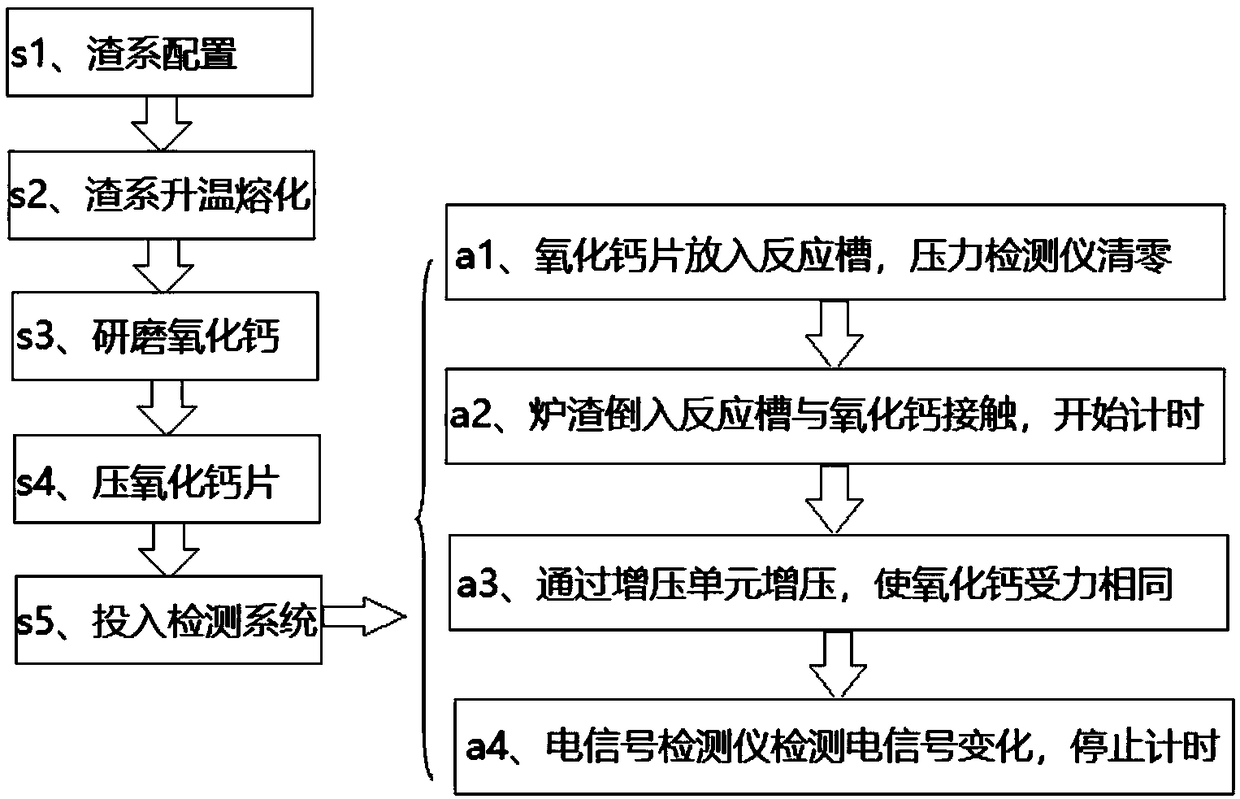

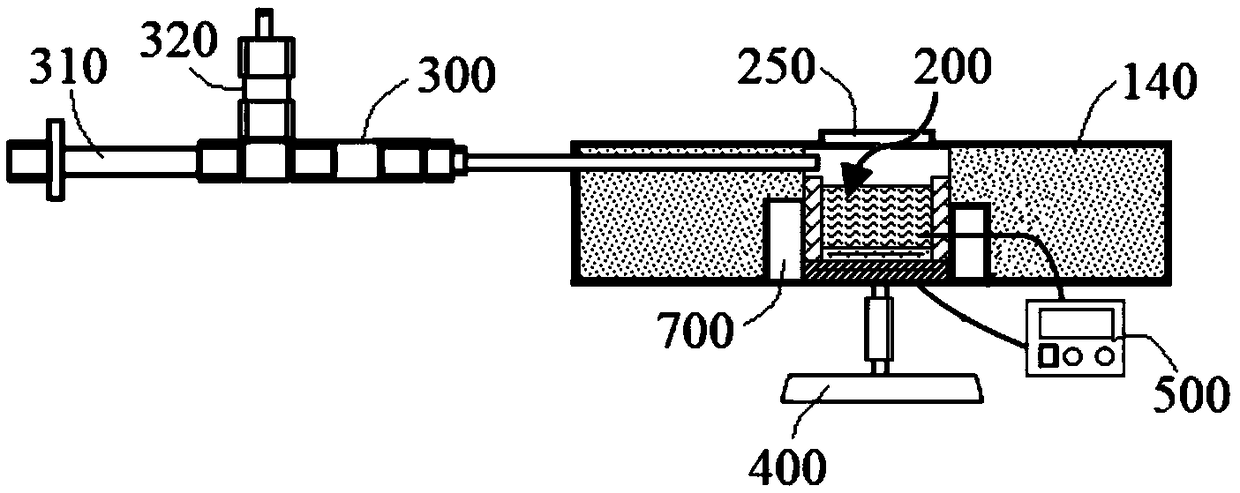

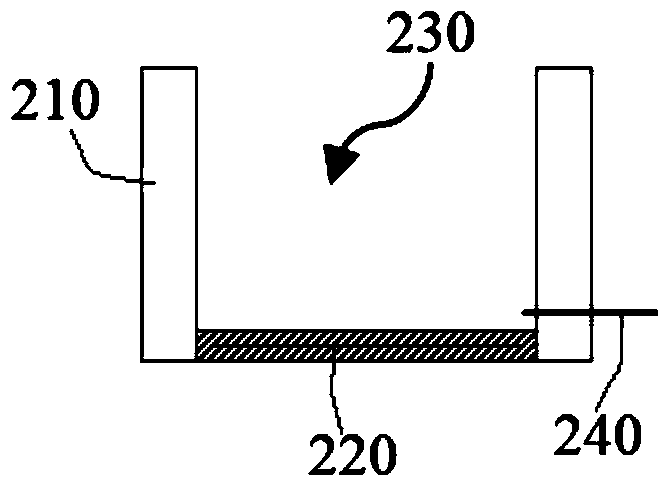

[0049] Such as Figure 1-Figure 4 As shown, a method for detecting the reaction performance of slag in this embodiment adopts a special detection system for the reaction performance of slag, and proceeds according to the following steps:

[0050] S1. Slag system configuration: the slag system is configured with pure chemical reagents CaO and SiO 2 , 3CaO·P 2 o 5 , FeC 2 o 4 as raw material;

[0051] S2, slag system heating treatment: Weigh the quantitatively prepared slag and put it into the heating furnace to heat, so that the slag sample is evenly melted; specifically, weigh the quantitative slag (such as 200g) and put it into the heating furnace, and the furnace temperature is set at 1200- 1400°C, the heating process is three-stage heating, firstly keep warm for 30-40min under the temperature conditions of 300-400°C and 700-800°C, respectively, to prevent the slag sample from being heated unevenly during the melting process of the slag sample due to excessive heating, ...

Embodiment 2

[0067] A method for detecting the reactivity of slag in this embodiment is basically the same as in Embodiment 1, except that it is different in the following steps:

[0068] S2. Slag system heating treatment: Weigh quantitative slag and put it into the heating furnace. The furnace temperature is set at 1400°C. The heating process is three-stage heating. First, keep the temperature at 300°C and 700°C for 30 minutes respectively, and wait for the temperature to rise. At 1400°C, keep warm for another 30 minutes to ensure sufficient reaction between the compounds and then carry out the detection operation;

[0069] S3. Grinding to prepare calcium oxide powder: crush and grind blocky calcium oxide into small particles of calcium oxide in a mortar, then use a 100-mesh round hole sieve to sieve, and put the sieved material into an agate mortar and continue fine grinding for 15 minutes Above, make it pass through a 200-mesh round hole sieve, and use it now to prevent water absorption...

Embodiment 3

[0073] A method for detecting the reactivity of slag in this embodiment is basically the same as in Embodiment 1, except that it is different in the following steps:

[0074] S2. Slag system heating treatment: Weigh quantitative slag and put it into the heating furnace. The furnace temperature is set at 1200°C. The heating process is three-stage heating. First, keep the temperature at 400°C and 800°C for 40 minutes respectively, and wait for the temperature to rise. Keep warm for another 40 minutes at 1200°C;

[0075] S3. Grinding and preparing calcium oxide powder: crush and grind blocky calcium oxide into small particles of calcium oxide in a mortar, then use a 150-mesh round hole sieve to sieve, and put the sieved material into an agate mortar and continue fine grinding for 15 minutes Above, make it pass through a 250-mesh round hole sieve, and use it now to prevent water absorption and deterioration;

[0076] S4. Compressing calcium oxide tablets: under a pressure of 12 M...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com