Grinding and screening device for soil heavy metal detection

A screening device and heavy metal technology, applied in the direction of measuring devices, preparation of test samples, analysis of materials, etc., can solve the problems of long time, low efficiency, and affecting the health of experimenters, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

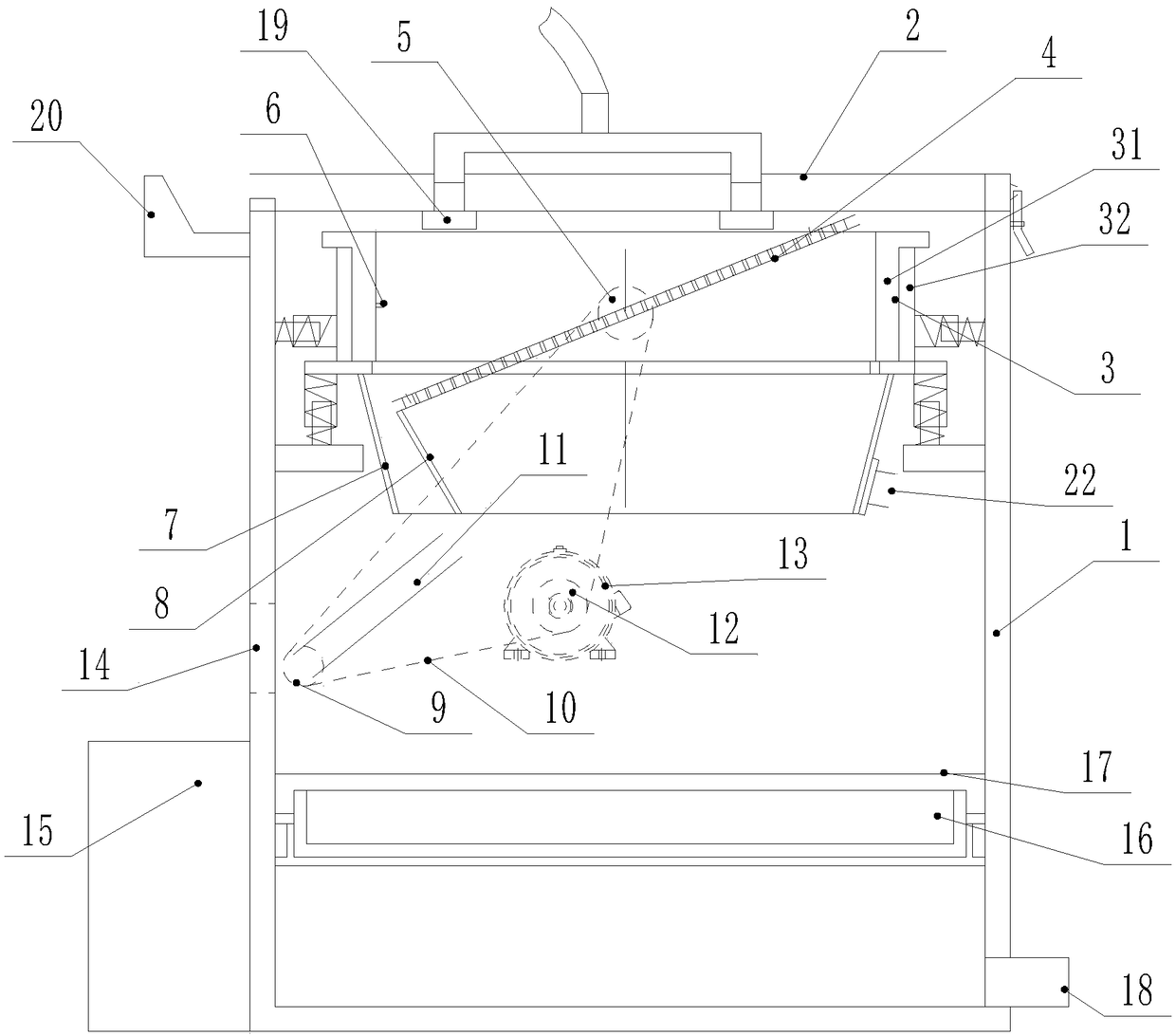

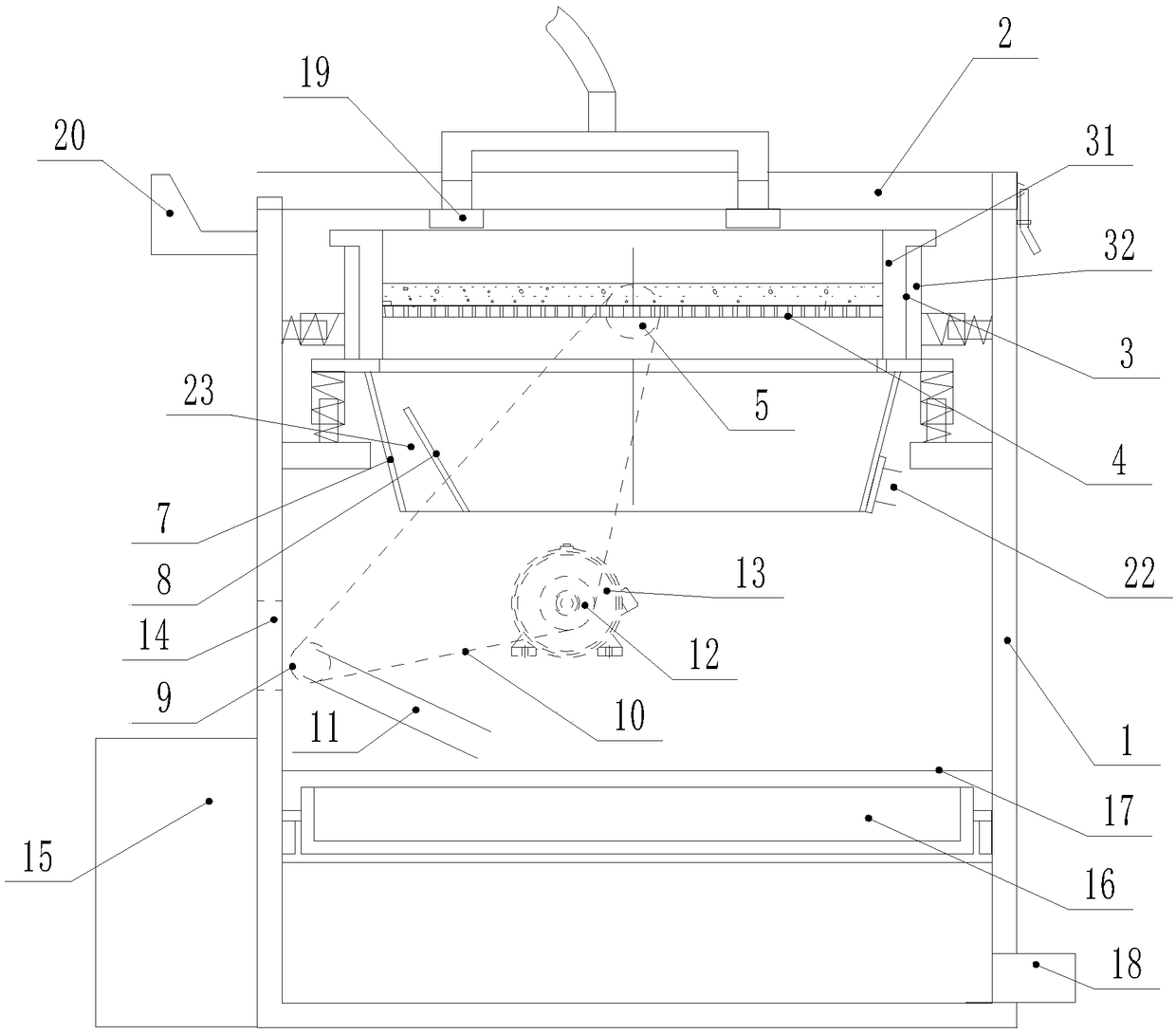

[0024] Such as Figure 1 to Figure 2 As shown, the grinding and screening device for soil heavy metal detection includes a casing, and a grinding filter screen 3 with grinding balls is installed in the casing, and the grinding filter screen 3 is driven to vibrate by a vibration motor 22. In this embodiment , the lower end of the grinding filter screen 3 is fixed with a guide hopper, and the vibrating motor 22 is fixed on the outside of the guide hopper 7 and then drives to vibrate. A first central axis is provided, and the bottom plate 4 is installed in the grinding filter screen 3 by swinging through the first central axis. A guide hopper 7 is provided under the casing, and a guide hopper 7 located on the bottom of the casing is slidably installed. For the collection box 16 below, the side wall of the casing is equipped with a discharge door 17 corresponding to the collection box 16, and a guide plate 12 is installed in the casing through the deflection of the second central ...

Embodiment 2

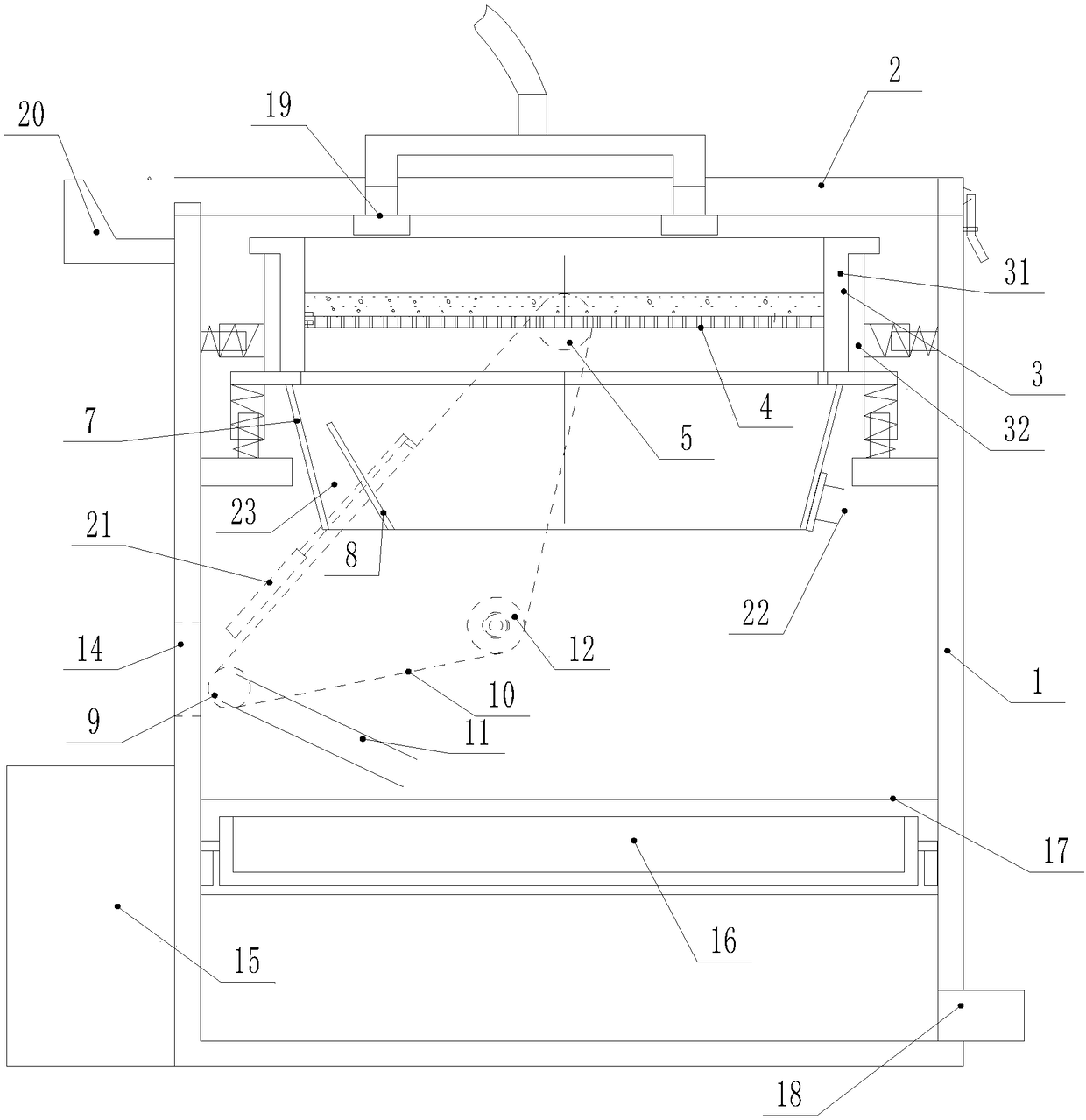

[0030] The structure of this embodiment is the same as that of Embodiment 1, except that the power unit includes a cylinder 21, and the cylinder body of the cylinder 21 is fixed outside the casing, and the piston rod of the cylinder 21 is connected to one of the straight lines of the drive chain 10 through the connecting block. segment connection, the telescoping direction of the piston rod is parallel to the straight segment. The connecting block is directly connected to one of the chain links of the driving chain 10, and then the piston rod is fixed to the connecting block again. The expansion and contraction of the piston rod of the cylinder 21 can push or pull the driving chain 10 to run, thereby driving the positive and negative deflection of the bottom plate 4.

[0031] The actuators such as the cylinder 21, the motor 13, and the sprocket drive mentioned in this embodiment are all current conventional technologies. In April 2008, the fifth edition of the Mechanical Design...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com