Pressure control electromagnetic valve for automatic transmission

An automatic transmission and pressure control technology, which is applied in transmission control, valve details, multi-way valves, etc., can solve problems such as low response characteristics and high oil viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

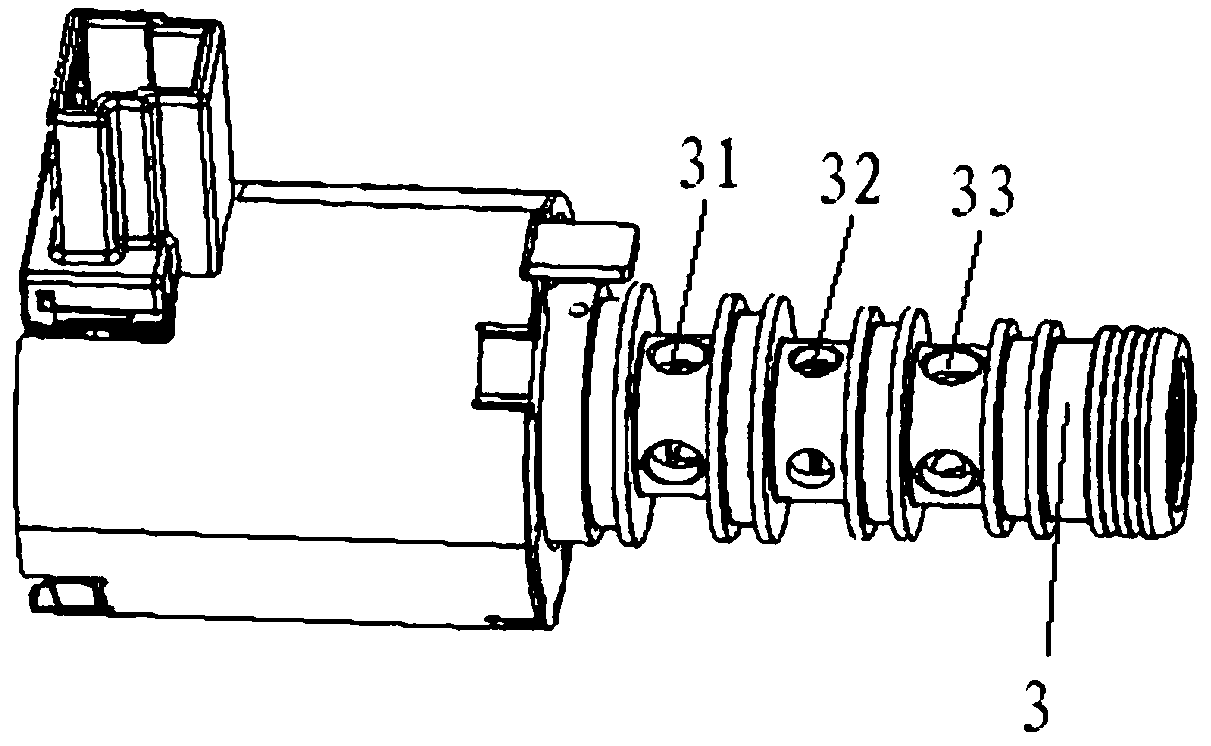

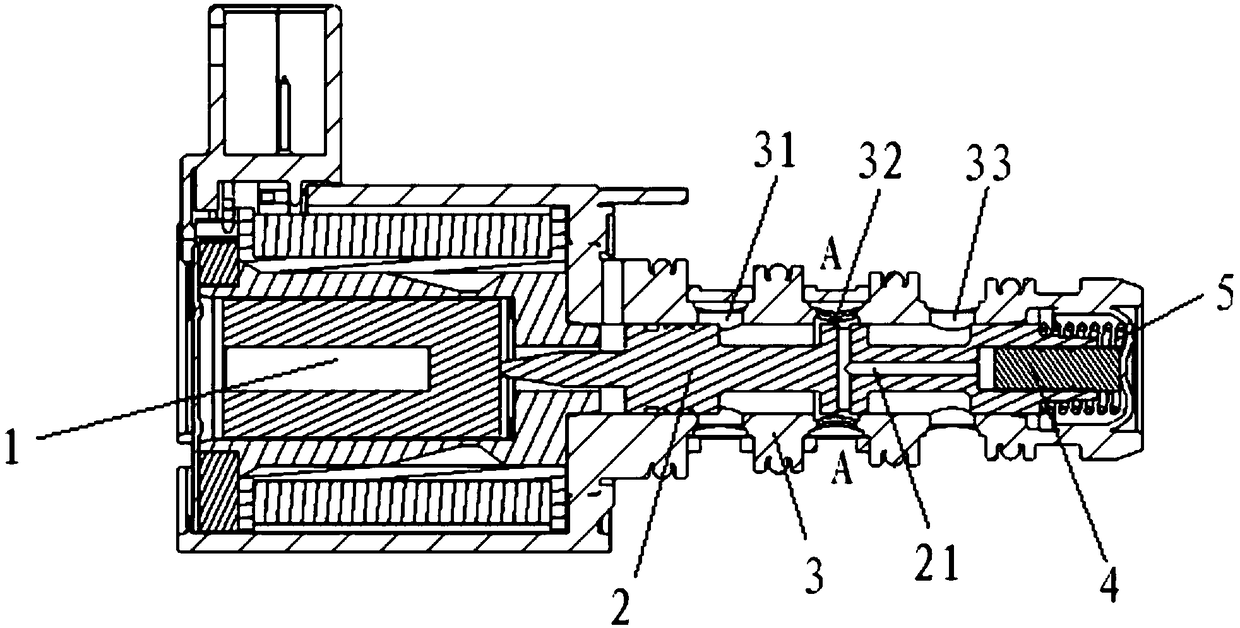

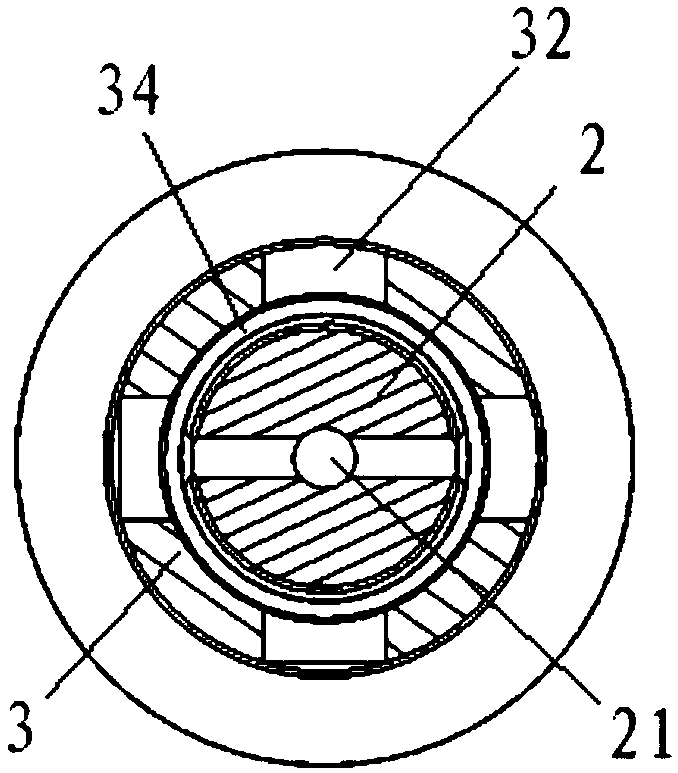

[0038] In order to enable those skilled in the art to better understand the solutions of the embodiments of the present invention, the embodiments of the present invention will be further described in detail below in conjunction with the drawings and implementations.

[0039] Due to the increase of the viscosity of the oil in the gearbox at low temperature, the response characteristics of the solenoid valve will be greatly reduced, which may cause problems such as slow response of the whole vehicle and shocks that are likely to cause customer complaints. The invention provides a pressure control electromagnetic valve used in an automatic gearbox. A plurality of oil supply ports, oil outlets and oil discharge ports are arranged on the valve sleeve to increase the circulation space of the working oil. It solves the problem that the existing electromagnetic valve has a high oil viscosity in the gearbox and easily has low response characteristics, can improve the response speed of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com