Excavator movable arm hydraulic control system and lifting control method

A technology of hydraulic control system and mobile arm, which is applied to mechanically driven excavators/dredgers, earth movers/shovels, construction, etc., and can solve the problem of reduced digging force of the stick, slow digging efficiency, and lower stroke of the boom Long-term problems, to achieve the effect of reducing fuel consumption and improving operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific implementation will be described below in conjunction with the accompanying drawings.

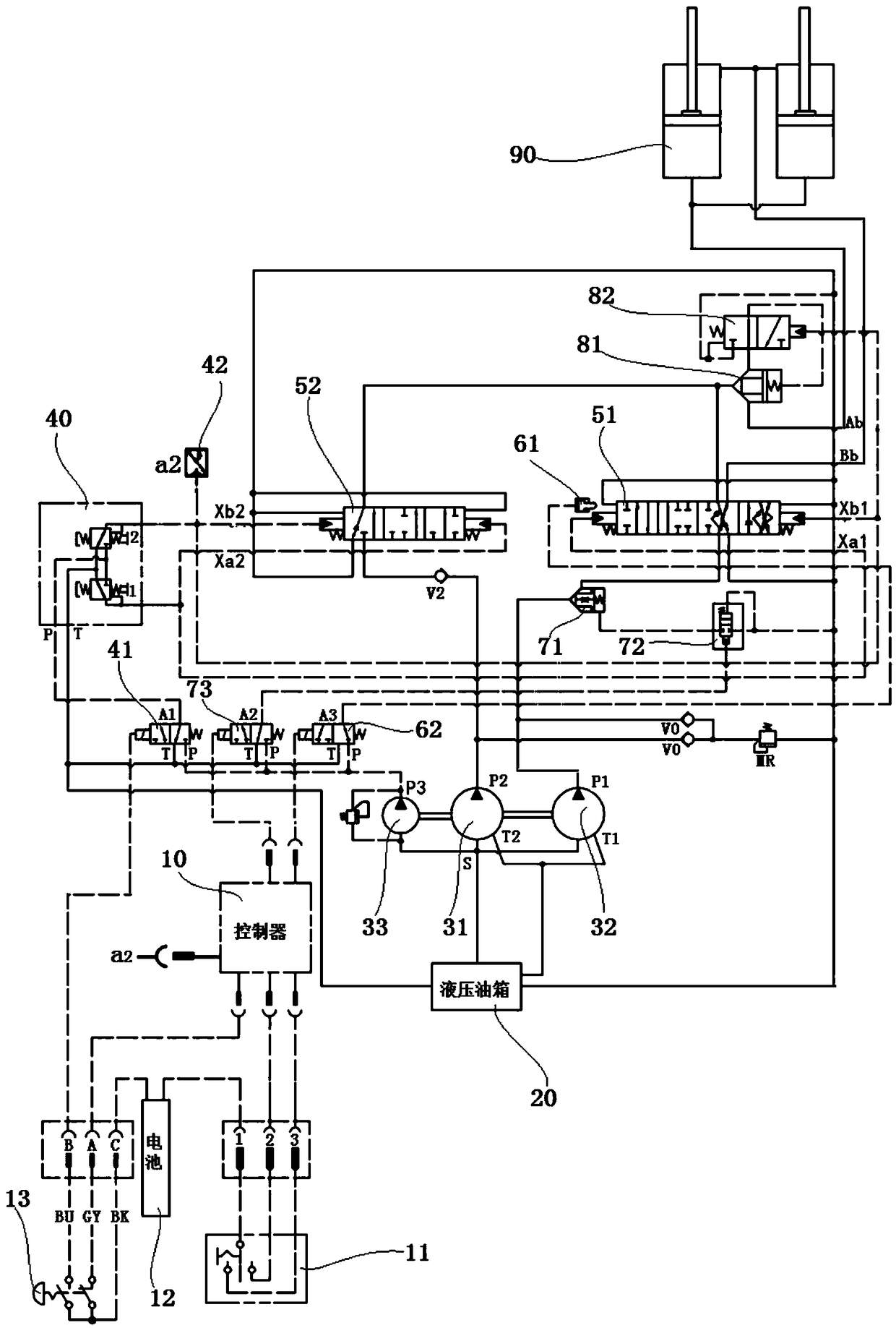

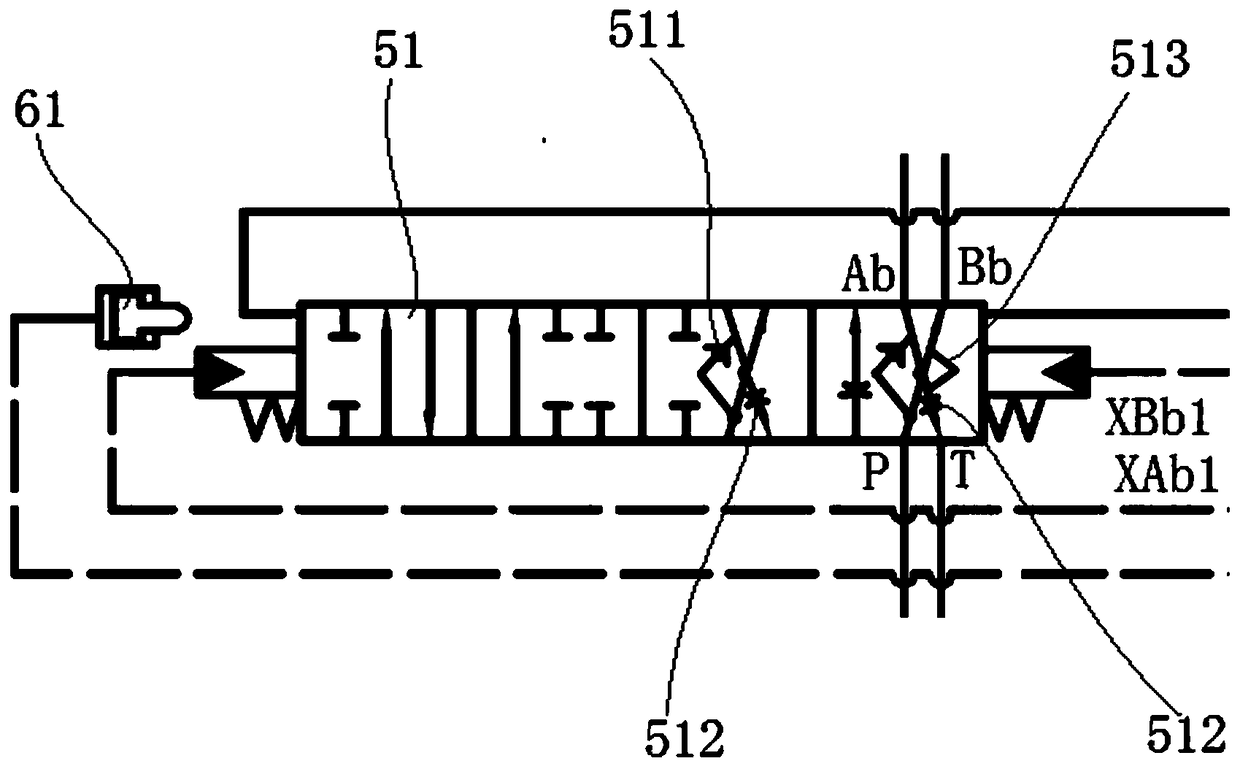

[0029] Such as figure 1 As shown, the excavator arm hydraulic control system in this embodiment includes a lift confluence valve 52 and a control main valve 51 for controlling the boom cylinder 90, and a liquid control terminal connected with the lift confluence valve 52 and the control main valve 51 The connected pilot control device, the hydraulic oil tank 20 connected to the oil tank circuit, the left pump 31 , the right pump 32 and the pilot pump 33 connected to the oil inlet S and the hydraulic oil tank 20 .

[0030] The pump port P2 of the left pump 31 is connected to the working oil inlet port of the lift confluence valve 52 through the one-way valve V2, and the connection port of the large cavity of the boom cylinder of the lift confluence valve 52 is connected to the large cavity of the boom cylinder of the control main valve 51 The ports are connected to the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com