Cu-Ti3AlC2 composite material and preparation method thereof

A composite material and mixing technology, which is applied in the field of Cu-Ti3AlC2 composite material and its preparation, can solve the problems of insufficient hardness and poor strength, and achieve the goal of improving electrical conductivity and mechanical properties, improving bending strength, and increasing compactness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

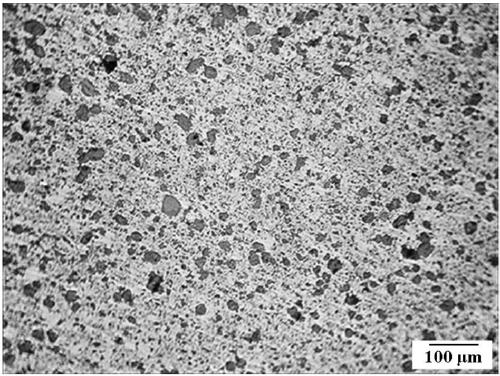

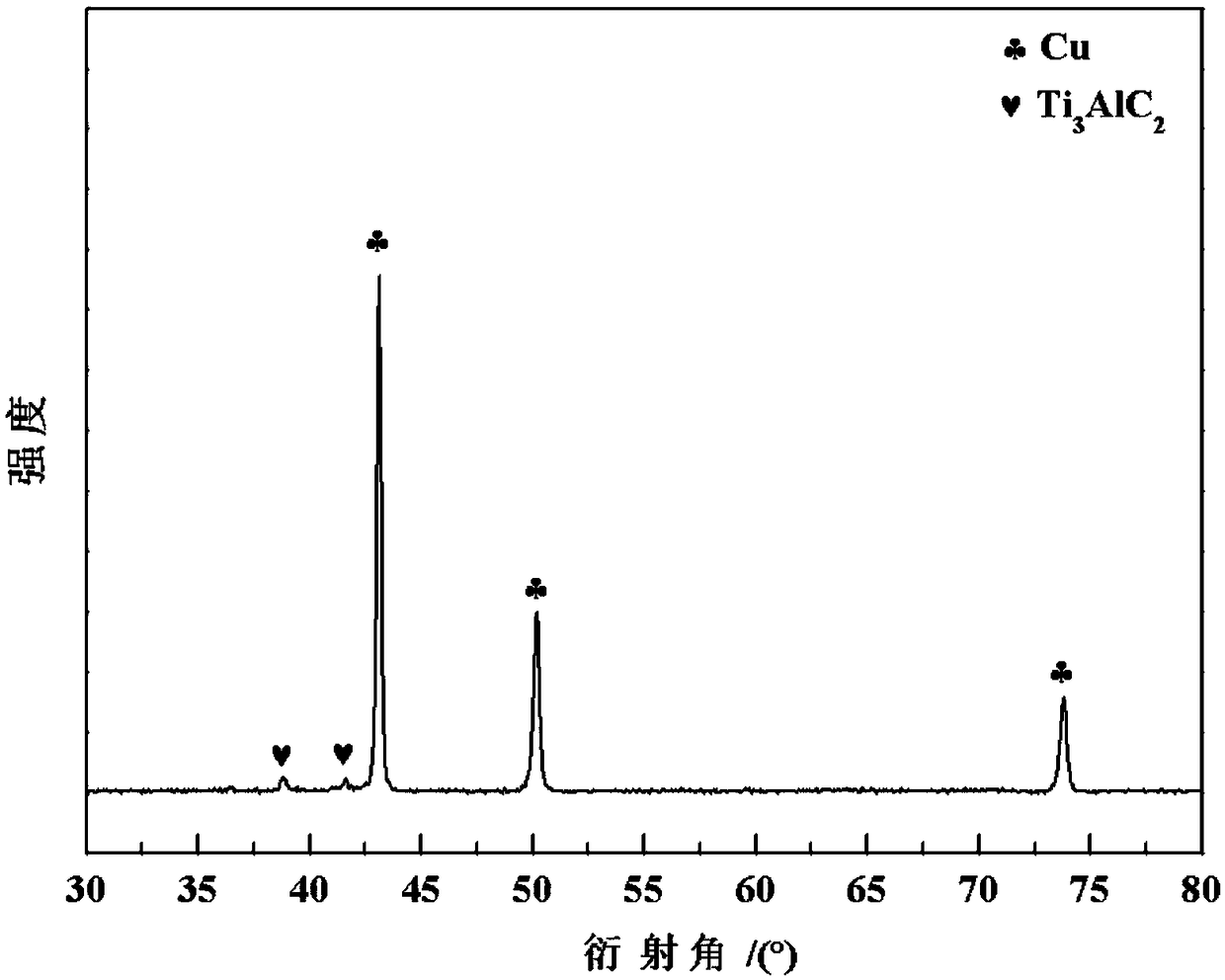

[0017] A kind of Cu-Ti 3 AlC 2 Composite material, with metal copper powder as the matrix phase and ceramic phase Ti 3 AlC 2 In order to strengthen the phase, the volume percentage of metallic copper powder in the composite material is 60%; the Cu-Ti 3 AlC 2 The composite material consists of metallic copper powder and Ti 3 AlC 2 The powder is prepared through the process steps of initial pressing-sintering-repressing.

[0018] The preparation method includes the following steps:

[0019] (1) Reduction of metal copper powder: pre-reducing the metal copper powder in a reducing atmosphere to obtain reduced copper powder;

[0020] (2)Ti 3 AlC 2 Obtained powder: Ti 3 AlC 2 Grind the particles to Ti with a particle size of 5~10μm 3 AlC 2 powder;

[0021] (3) Mixing: According to the volume percentage of metal copper powder in the composite material as 60%, the copper powder and Ti are reduced 3 AlC 2 The powder is evenly mixed to obtain a mixture;

[0022] (4) Powder pressing: adding the mix...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com