High-carbon chromium bearing steel continuous casting blank heating control method based on temperature time control

A high-carbon chromium bearing steel, heating control technology, applied in the direction of heat treatment process control, heat treatment furnace, manufacturing tools, etc., can solve the problems of excessive decarburization, uneven diffusion of bearing steel, inability to know the temperature of bearing steel, etc. The effect of improving heating quality and rolling production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

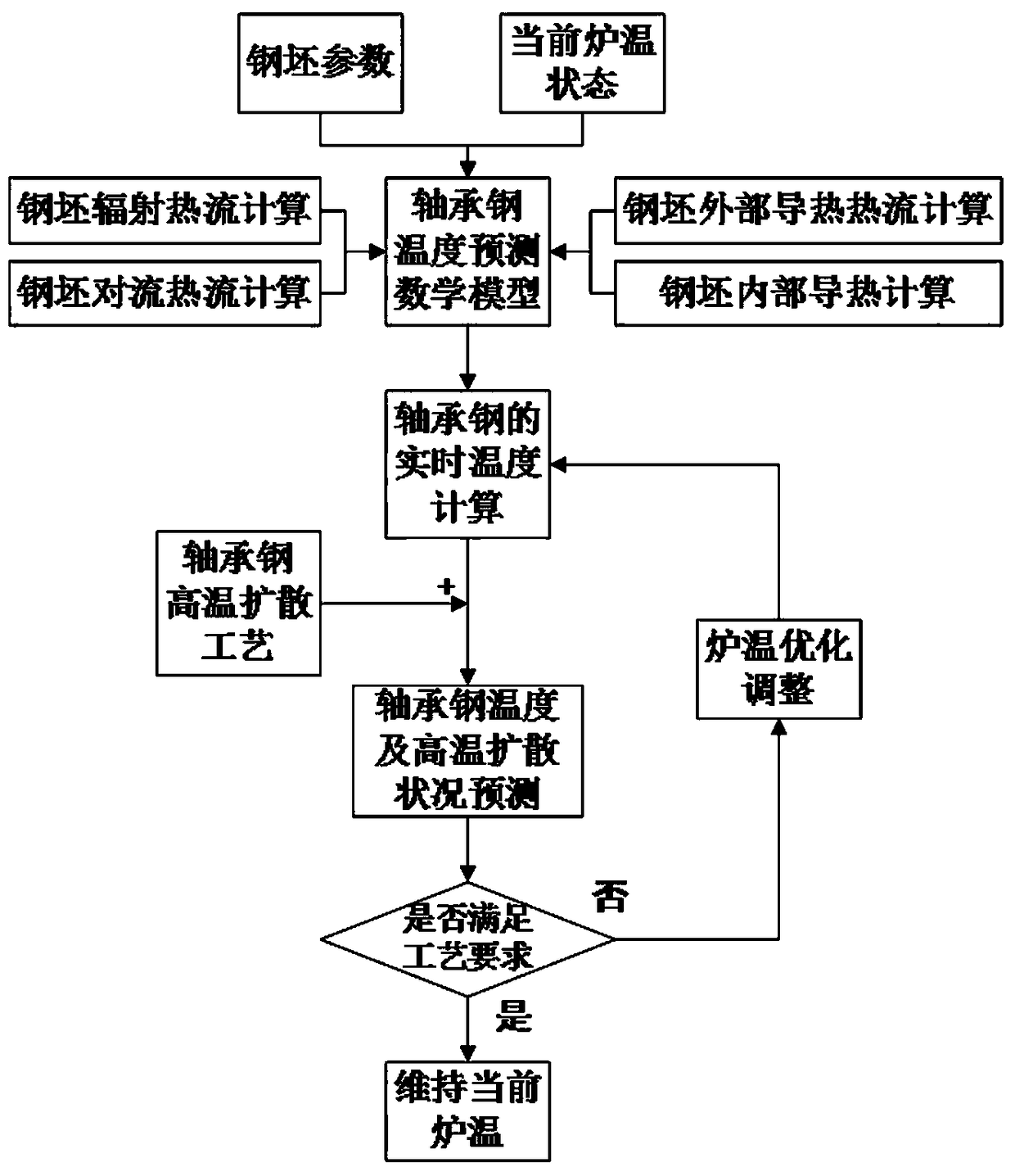

Method used

Image

Examples

Embodiment 1

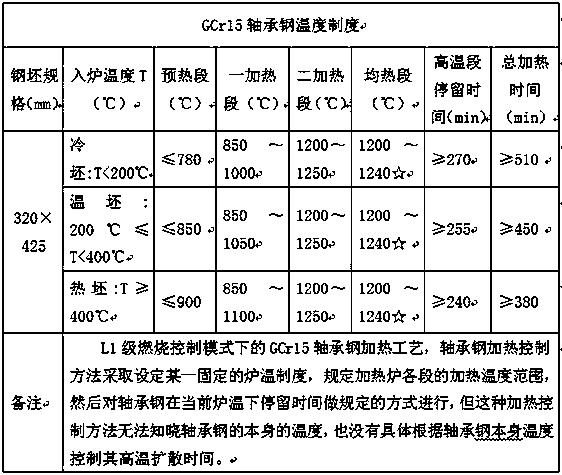

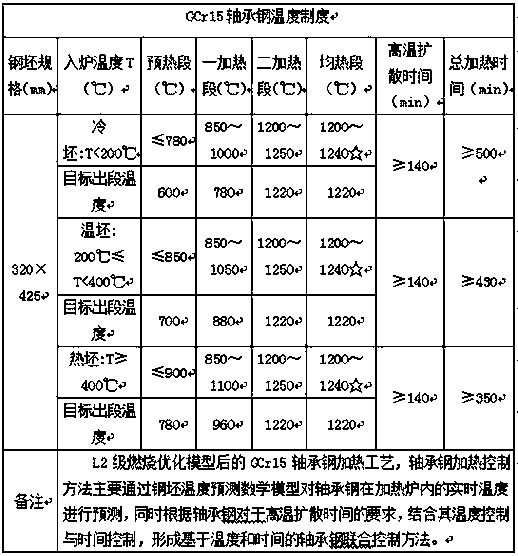

[0040] Let’s make another explanation based on the adjustment and optimization of the heating process before and after the adoption of the L2 combustion optimization model in a certain factory.

[0041] The GCr15 bearing steel heating temperature system under the L1 combustion control mode before the L2 combustion optimization model is adopted (see Table 1), and the GCr15 bearing steel heating temperature system after the L2 combustion optimization model is adopted (see Table 2):

[0042] Table 1

[0043]

[0044] Table 2

[0045]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com