Mutant strain for high yield of gamma-aminobutyric acid and biological agent of mutant strain

A technology for mutagenizing strains and aminobutyric acid, applied in the directions of microorganism-based methods, microorganisms, microorganisms, etc., can solve the problems of increasing product production costs, detrimental to body health, and affecting food flavor and taste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0085] Embodiment 1, experimental material

[0086] Starting strain:

[0087] 1. Lactobacillus plantarum is the frozen strain Lp20160820 of our company.

[0088] 2. Lactobacillus rhamnosus: selected from the mutagenic strain Lactobacillus rhamnosus KJY11, the preservation number is CGMCC No.15421, and the preservation date is March 07, 2018.

[0089] 3. Lactobacillus zea: selected from the mutagenic strain Lactobacillus zea KJY13, the preservation number is CGMCC No.15423, and the preservation date is March 07, 2018.

[0090] 4. Lactobacillus casei: selected from the mutagenized strain Lactobacillus casei (Lactobacillus casei strain) KJY14, the preservation number is CGMCC No.15424, and the preservation date is March 07, 2018.

[0091] 5. Leuconostoc mesenteroides strain: selected from the mutagenic strain Leuconostoc mesenteroidesstrain KJY15, the preservation number is CGMCC No.15425, and the preservation date is March 07, 2018.

[0092] 6. MRS liquid medium: peptone 10g / ...

Embodiment 2

[0097] Embodiment 2, microwave mutagenesis Lactobacillus plantarum

[0098] The frozen Lactobacillus plantarum strains were respectively activated twice in the MRS liquid medium, and then spread on the MRS solid medium by the concentration gradient method. Anaerobic culture was carried out at 37°C for 20-30 hours, and a single colony with obvious calcium dissolution circle was selected for streak purification after plate counting. The final single colonies obtained were purified for 3 generations.

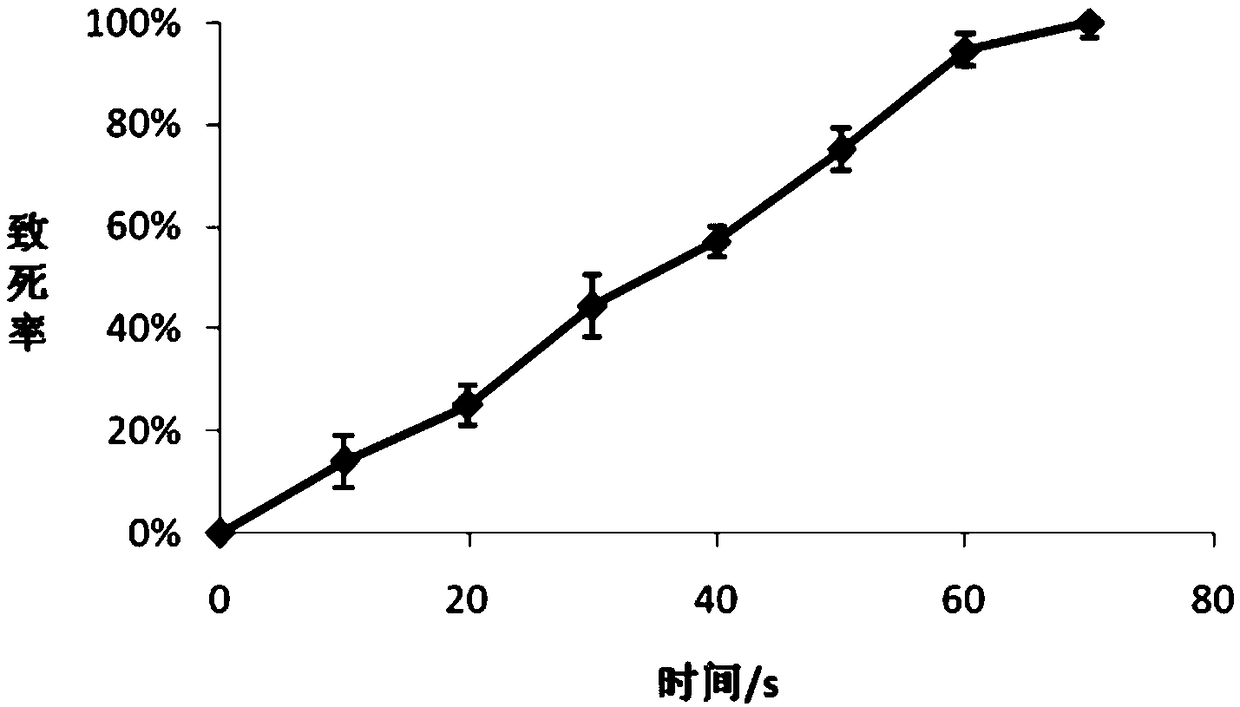

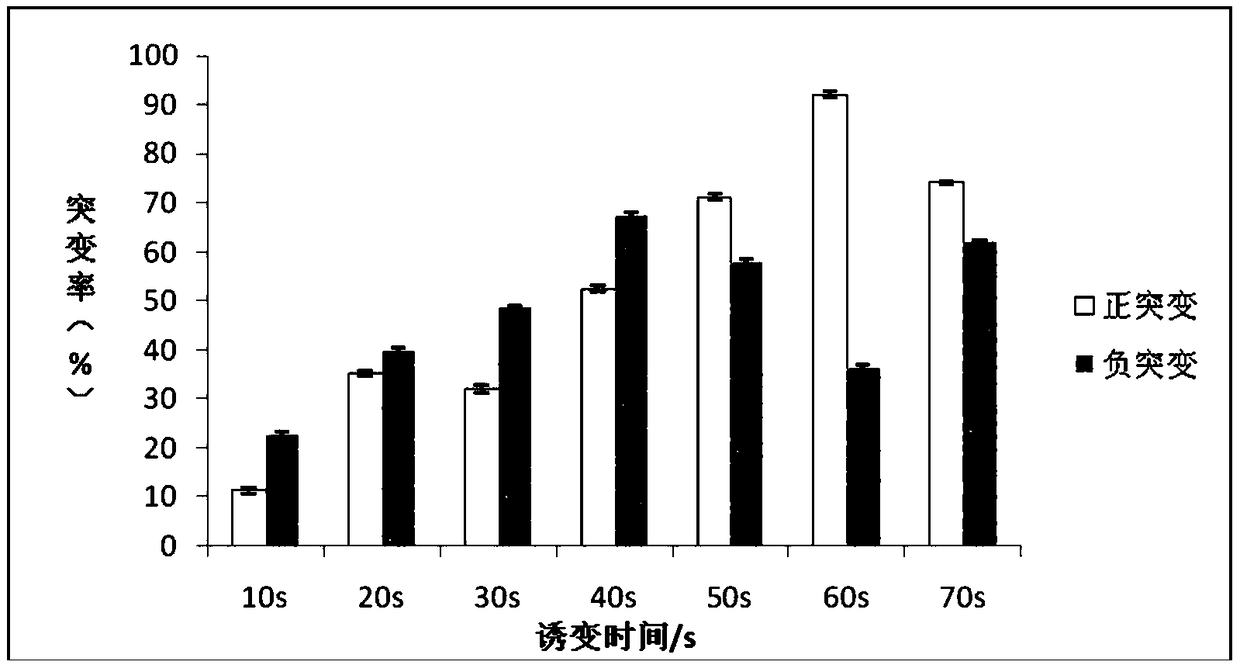

[0099] Collect strains and dilute to 10 7 / ml of bacterial suspension, placed in a microwave oven with a power of 500W, and the irradiation time was 10, 20, 30, 40, 50, 60, 70, 80, 90s, respectively. Take it out every 10s and use an ice bath for 10s to eliminate the thermal effect of the microwave. After refrigerated at 4°C for 12h in the dark, spread on the MRS solid medium plate, incubate at 37°C for 24h, count the colonies, and calculate the lethality.

[0100] Using 500 powe...

Embodiment 3

[0107] Embodiment 3, nitrosoguanidine mutagenesis

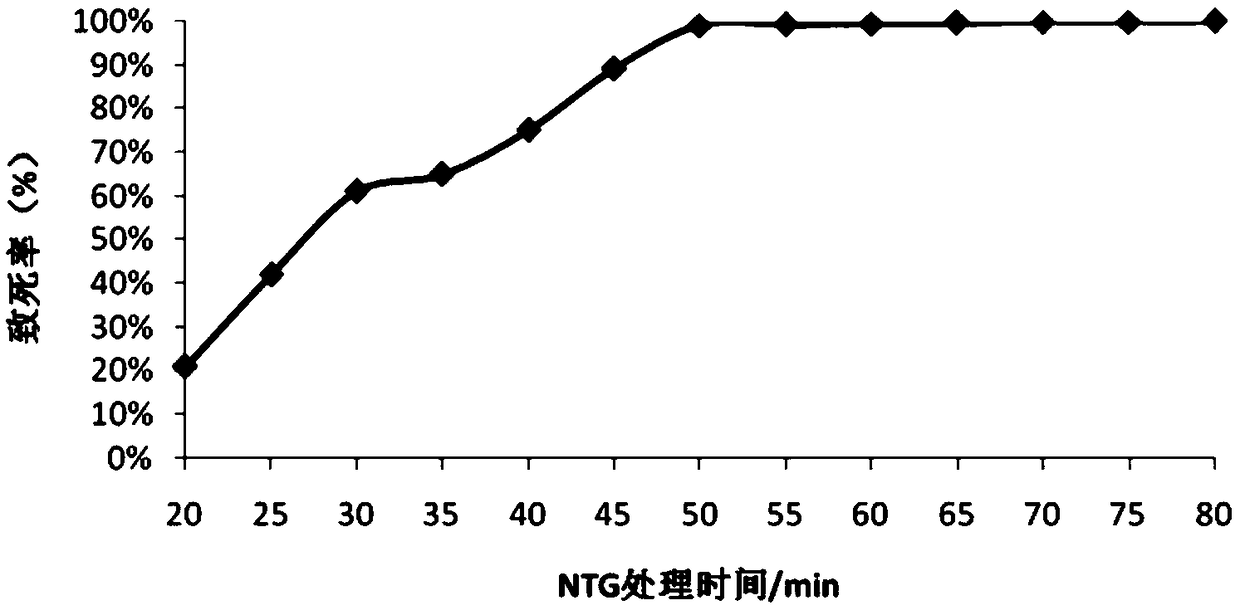

[0108] Nitrosoguanidine (NTG): Take 0.1g of nitrosoguanidine and add 10mL of acetone as co-solvent, after complete dissolution, take 1mL of nitrosoguanidine acetone solution and add 9mL of sodium phosphate buffer (pH7.4, 0.02mol / L) to prepare Prepare a nitrosoguanidine stock solution with an NTG concentration of 1 mg / mL.

[0109] The cultivated Lactobacillus plantarum was collected and diluted to 10 8 / ml of bacterial suspension. Then take 8 mL of bacterial suspension, add 2 mL of nitrosoguanidine stock solution, and the final concentration of NTG is 200 μg / mL, and set the non-mutated stock solution as a control.

[0110] Put the above-mentioned bacterial solution in a conical flask, incubate on a shaking table at 37°C in the dark for 10, 15, 20, 25, 30, 35, 40, 45, and 50 min, then add physiological saline to terminate the reaction; After the bacterial solution was ice-bathed for 2-3 hours to induce the positive mutation,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com