Graphene chemical-resistant and weather-resistant heat-conduction plastic and preparation method thereof

A heat-conducting plastic and chemical-resistant technology, applied in the field of materials, can solve the problems of poor chemical resistance, poor dimensional stability, and easy deformation of heat-conducting plastics, and achieve the effects of improved weather resistance and aging resistance, good dimensional stability, and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

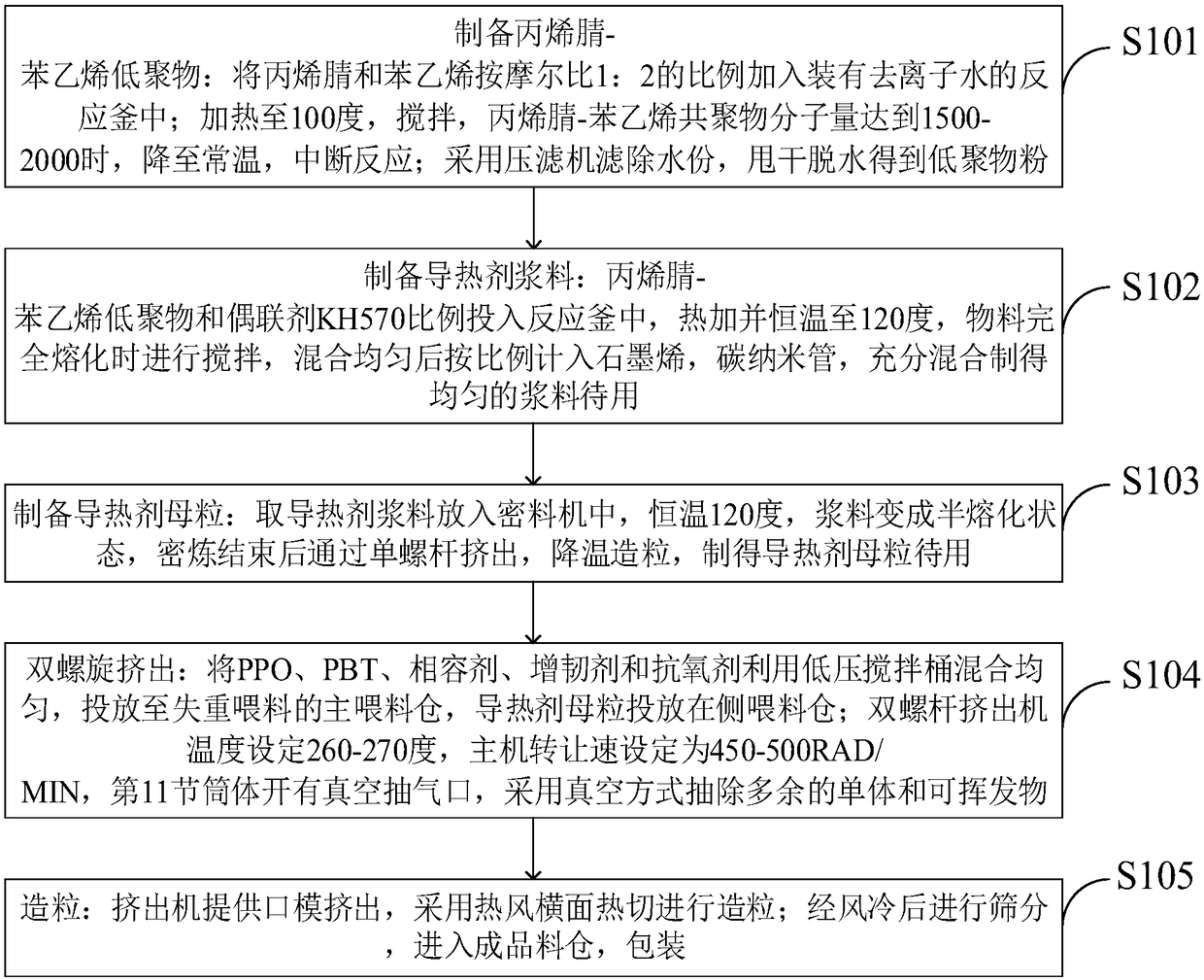

[0040] Such as figure 1 As shown, the preparation method of the graphene chemical-resistant weather-resistant thermally conductive plastic provided by the embodiment of the present invention comprises:

[0041] S101: Preparation of acrylonitrile-styrene oligomers: Add acrylonitrile and styrene in a molar ratio of 1:2 into a reactor filled with deionized water; heat to 100 degrees, stir, and acrylonitrile-styrene copolymerization When the molecular weight of the product reaches 1500-2000, it is lowered to normal temperature, and the reaction is interrupted; the water is filtered out by a filter press, and the oligomer powder is obtained by drying and dehydration;

[0042] S102: Preparation of thermal conductivity agent slurry: acrylonitrile-styrene oligomer and coupling agent KH570 are put into the reaction kettle in proportion, heated and kept at a constant temperature to 120 degrees Celsius, stirred when the material is completely melted, mixed evenly, and added to the graphi...

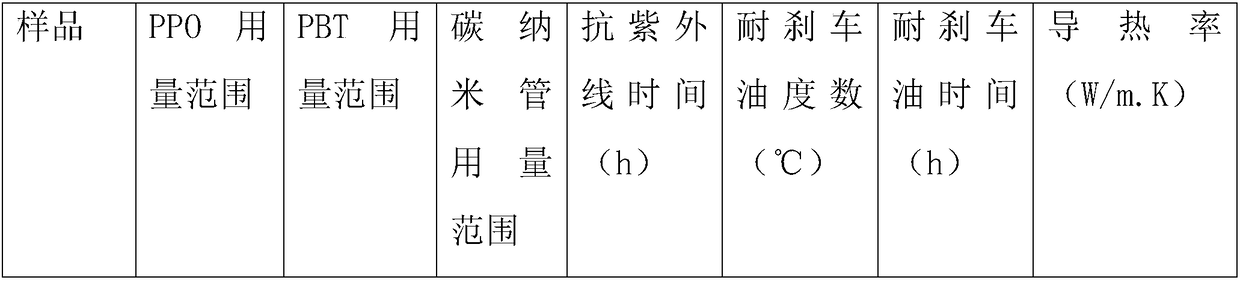

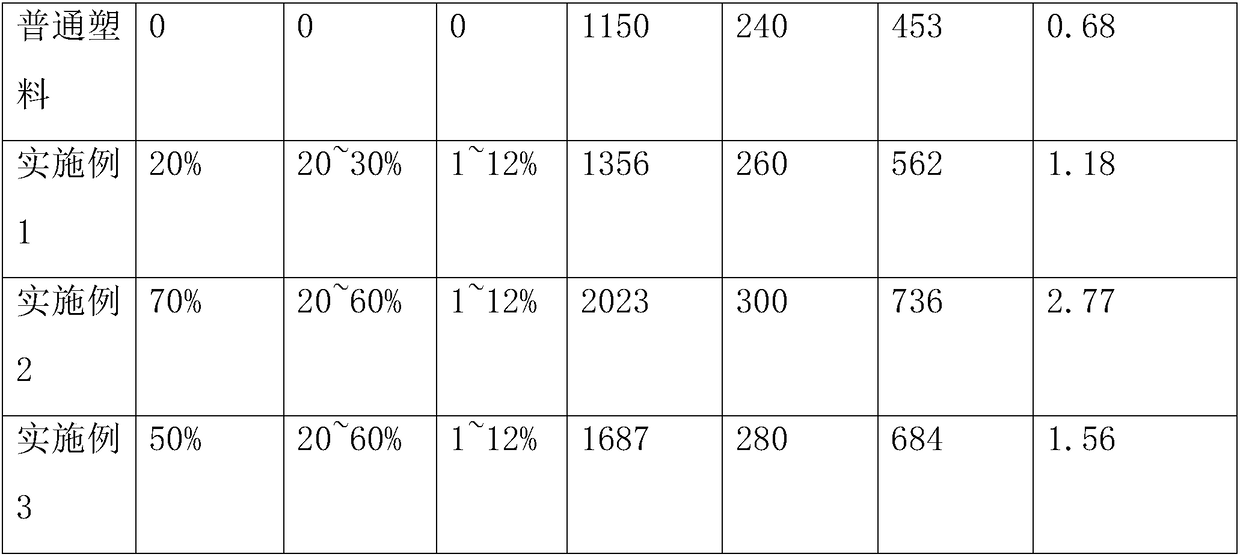

Embodiment 1

[0052] The graphene chemical-resistant, weather-resistant and thermally conductive plastic provided in the embodiments of the present invention is composed of phase A, phase B and phase C;

[0053] Phase A provided by the invention: PPO, is the basic plastic, and the dosage range is 20%.

[0054] Phase B provided by the present invention: consists of PBT, graphene, carbon nanotubes, compatibilizer KS-09 and toughening agent W5S; PBT is the basic plastic, and the preferred dosage range is 20-30%; Heat conduction agent, 3-10 layers, the dosage range is 1-12%, the preferred dosage range is 2-8%; carbon nanotubes are high-efficiency heat-conductive agents, the dosage range is 1-12%, the preferred dosage range is 2-8% ; Compatibilizer KS-09, the dosage range is 1-6%, the preferred dosage range is 2-4%; toughening agent W5S, the dosage range is 3-15%, the preferred dosage range is 5-12%;

[0055] Phase C provided by the present invention: composed of acrylonitrile-styrene oligomer,...

Embodiment 2

[0057] The graphene chemical-resistant, weather-resistant and thermally conductive plastic provided in the embodiments of the present invention is composed of phase A, phase B and phase C;

[0058] Phase A provided by the present invention: PPO, is the basic plastic, and the dosage range is 70%.

[0059] Phase B provided by the present invention: consists of PBT, graphene, carbon nanotubes, compatibilizer KS-09 and toughening agent W5S; PBT is the basic plastic, and the dosage range is 20-60%, and the preferred dosage range is 20-60%. 30%; graphene is a high-efficiency heat-conducting agent, with 3-10 layers, the dosage range is 1-12%, and the preferred dosage range is 2-8%; carbon nanotubes are high-efficiency heat-conducting agents, the dosage range is 1-12%, The preferred dosage range is 2-8%; the compatibilizer KS-09, the dosage range is 1-6%, the preferred dosage range is 2-4%; the toughening agent W5S, the dosage range is 3-15%, the preferred dosage range is 5~12%;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com