Cross-linked elastomer cable material for high-voltage cables in vehicle, cable and preparation method thereof

A cross-linked elastomer and cable material technology, applied in the direction of circuits, insulators, electrical components, etc., can solve the problems of easy cracking of cables, achieve improved crack resistance, improve bending performance and crack resistance, and good heat resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] The present invention also provides a preparation method of the above cable, the preparation method comprising the following steps:

[0047] 1) Take SEBS, EPDM, HDPE, EVM, POE, POP and PE-g-MAH in the formula amount and add them to the mixer for mixing, and then plasticize and granulate the obtained mixture;

[0048] 2) The material obtained in step 1) is added to the remaining components of the formulation amount, mixed, and then kneaded, plasticized and granulated in a two-stage extruder; this two-stage extruder includes a twin-screw extruder and a single screw extruder;

[0049] 3) Place the material obtained in step 2) on the production line of the wire and cable extruder, extrude it in the extruder, coat it on the conductor core, and then perform irradiation processing. After irradiation, the thermal elongation is controlled at 15%~ 30% to form the final finished cable.

[0050] Preferably, in step 1, a twin-screw granulator is used for plasticizing and granulati...

Embodiment 1~8

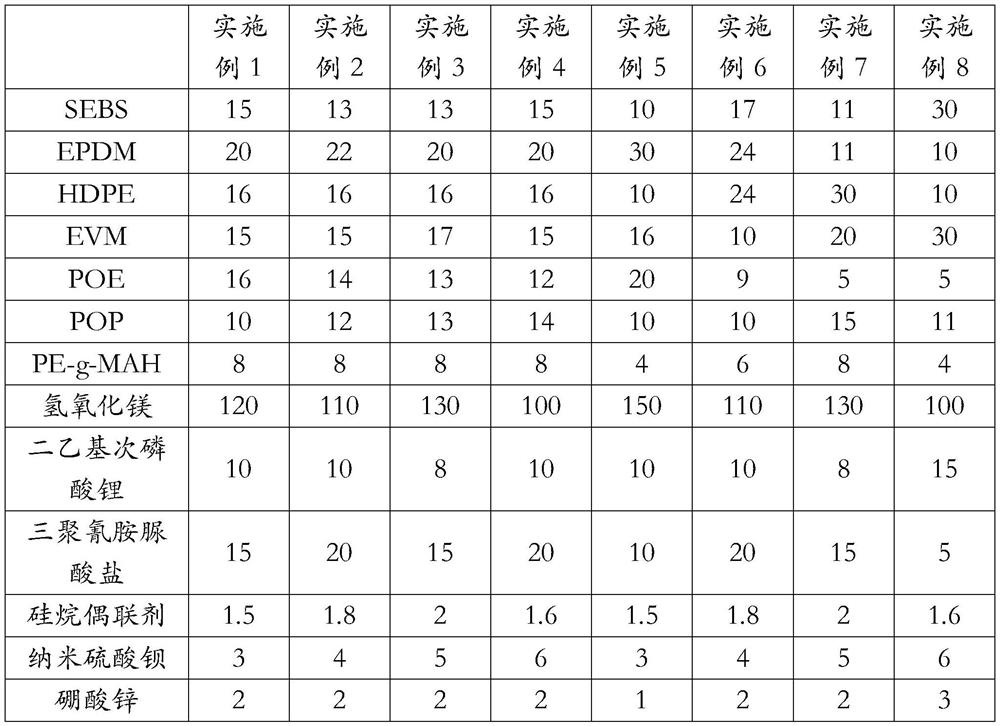

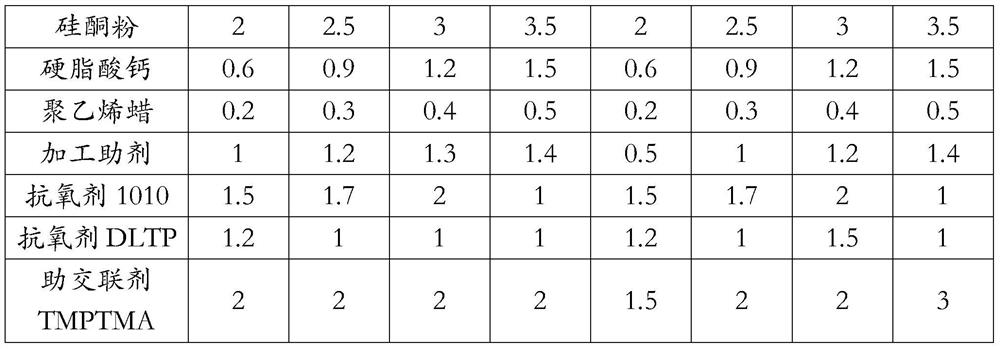

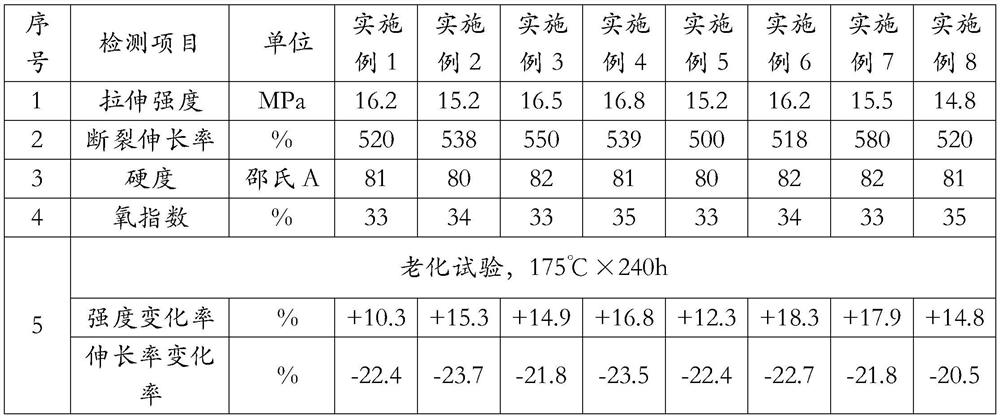

[0056] A cross-linked elastomer cable material for high-voltage cables in vehicles is used to prepare wires and cables for electric vehicles, and its formula is shown in Table 1 (the units of each component are parts by weight).

[0057] The formula of cable material in table 1 embodiment 1~8

[0058]

[0059]

[0060] In each of the above embodiments, the nano-barium sulfate is the precipitated barium sulfate Blanc Fixed F from Sahaliben, Germany, and the particle size distribution is about 15nm; the styrene content is 35% in the SEBS, and the molecular weight is 150,000 to 200,000; The ethylene content in EPDM is 70%, the Mooney viscosity (ML 1+4, 125°C) is 20MU; the melt index of the HDPE is 0.08-2g / 10min; the EVM is LANXESS EVM 500HV, and the VA content is 50% , Mooney viscosity (ML 1+4, 100°C) is 27; the POP is ExxonMobil Vistama xxTM special elastomer 6102, the ethylene content is 16%, and the melt index is 3g / 10min@230°C; the PE - The grafting rate of g-MAH is 0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com