A method for simultaneous catalytic oxidation of refractory pollutants in secondary effluent and degradation of excess sludge

A technology of excess sludge and secondary effluent, applied in chemical instruments and methods, water/sludge/sewage treatment, water/sewage treatment, etc., can solve the problems of high cost of excess sludge treatment and low utilization rate of resources.

Active Publication Date: 2022-06-03

HARBIN INST OF TECH

View PDF3 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] The present invention aims to solve the existing technical problems of high treatment cost of refractory pollutants or excess sludge in water and low resource utilization rate, and provides a method for synchronous catalytic oxidation of refractory pollutants and excess sludge in secondary effluent water The method uses the electricity generation and anodic degradation of the bioelectrochemical system and the high efficiency of the electro-Fenton catalytic oxidation technology to simultaneously degrade the remaining sludge and the refractory pollutants in the secondary effluent in one system

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

specific Embodiment approach 1

specific Embodiment approach 2

specific Embodiment approach 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

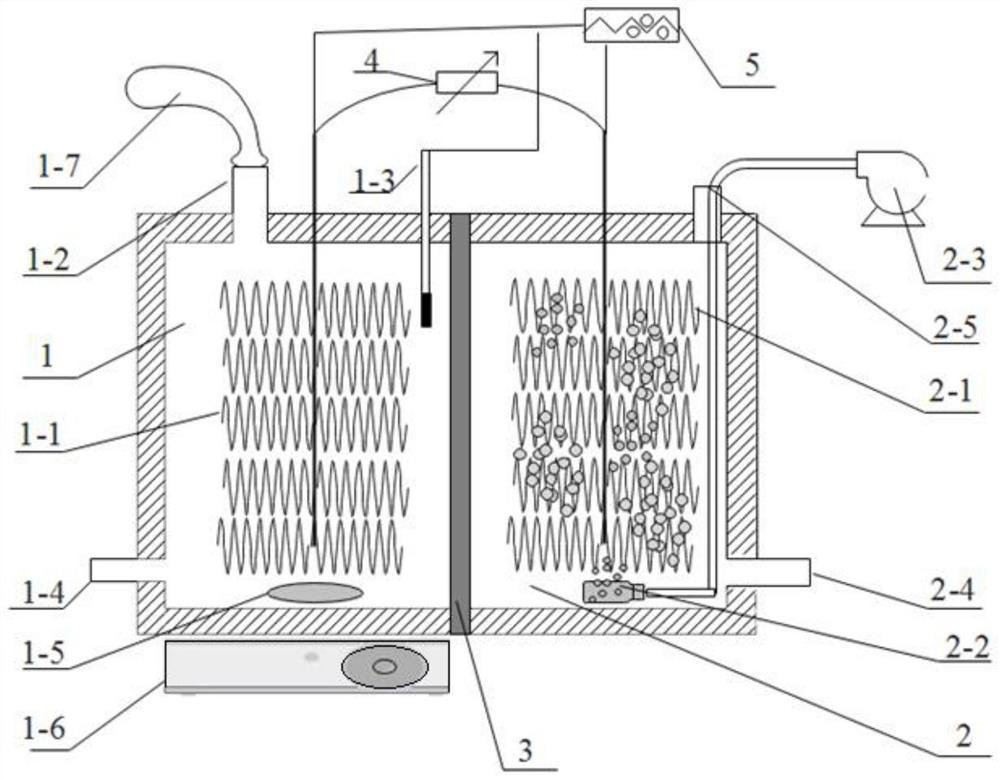

Login to View More Abstract

A method for simultaneously catalytically oxidizing refractory pollutants in secondary effluent and degrading excess sludge. It relates to a method for catalytic oxidation treatment of secondary tail water and degradation of excess sludge. It is to solve the existing problems of high cost of refractory pollutants and excess sludge in water, and low utilization rate of resources. This method: 1. Set up a bioelectrochemical coupling electric Fenton reaction system; 2. Add the nutrient solution and the electron acceptor solution to the anode chamber and the cathode chamber respectively, and inoculate the remaining sludge into the anode chamber, and use iron oxide The carbon brush is used as a composite cathode; cultivate until the output voltage is stable and greater than 0.65V, and the start-up is successful; 3. Add the remaining sludge to be treated and the secondary effluent containing refractory pollutants into the anode chamber and the cathode chamber respectively for synchronous processing; The treatment rate of refractory pollutants can reach 62%-99%, and the degradation rate of organic matter in excess sludge is 40%-65%. It can be used for simultaneous treatment of secondary effluent and excess sludge.

Description

A simultaneous catalytic oxidation of refractory pollutants in secondary effluent and degradation of excess sludge Methods technical field The invention belongs to bioelectrochemical technical field and advanced oxidation technical field, be specifically related to a kind of realization containing difficult A method for degrading the secondary effluent of the degraded pollutants and simultaneously realizing the degradation and recycling of excess sludge. Background technique As a kind of energy resource, biomass has been paid more and more attention. Contains a huge energy form, the chemical oxygen demand of 1kg biomass is equivalent to 4kW·h of energy. Microbial electrochemical systems are beneficial Using microorganisms as catalysts to convert chemical energy in biomass into electrical energy is an effective way to recover energy and resources. The emerging technology of the source has attracted widespread attention all over the world. The substrates in the MES ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C02F9/14C02F1/467C02F3/00C02F3/28

CPCC02F1/4672C02F3/005C02F3/2853C02F3/2866Y02A50/20

Inventor 赵庆良王维业王琨姜珺秋丁晶史珂

Owner HARBIN INST OF TECH

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com