Device and method for producing high purity oxygen by pressure swing adsorption

A pressure swing adsorption, high-purity technology, applied in chemical instruments and methods, oxygen preparation, separation methods, etc., can solve the problems of no industrial application, low adsorption selectivity, and low separation efficiency, so as to save energy and improve oxygen Purity, the effect of improving purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] In order to improve the total recovery rate of oxygen and the purity of product oxygen, the present invention improves the existing two-stage series pressure swing adsorption oxygen production technology, and proposes a device and method for preparing high-purity oxygen by pressure swing adsorption.

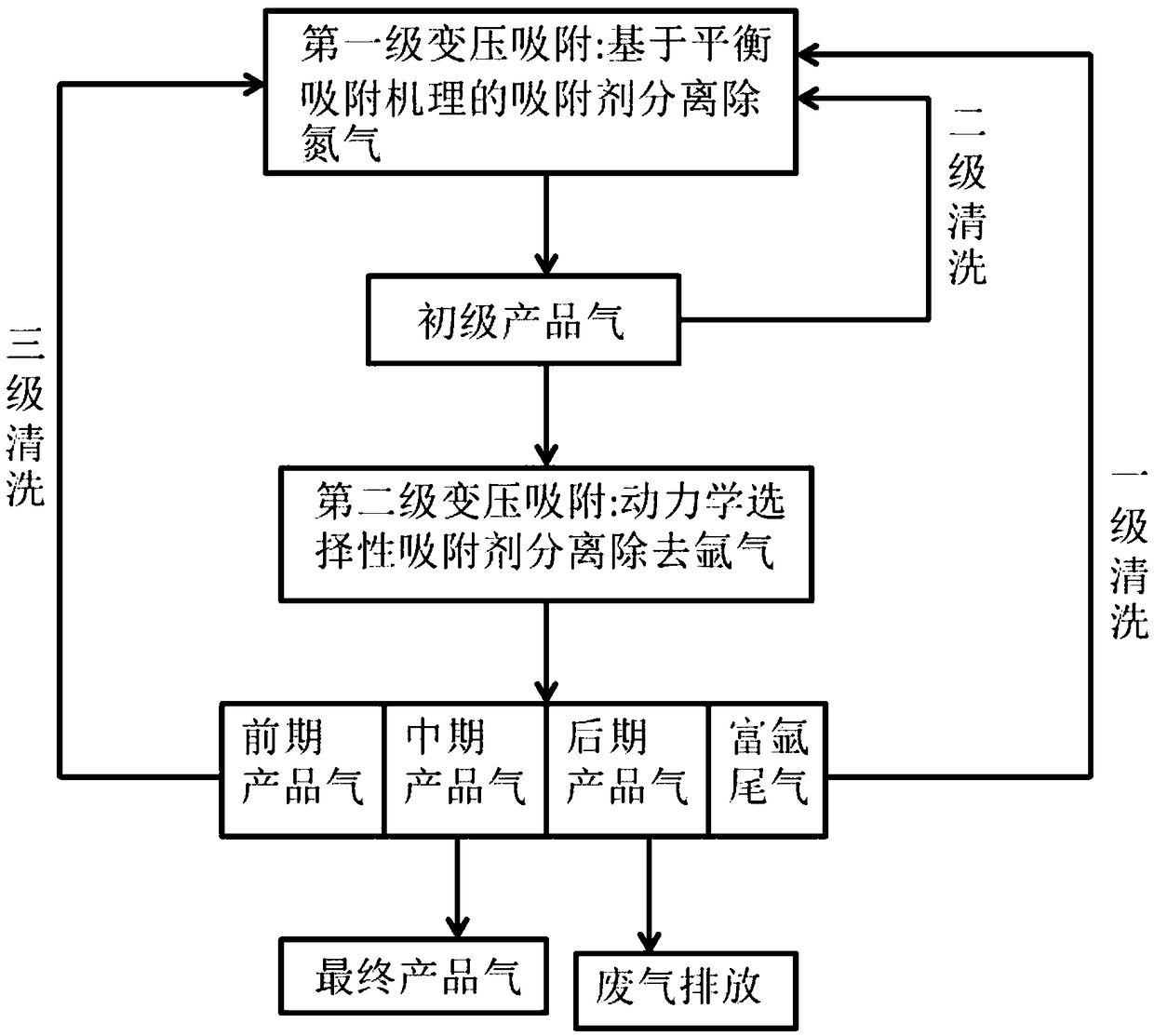

[0033] Such as figure 1 As shown, a method for preparing high-purity oxygen by pressure swing adsorption includes a two-stage pressure swing adsorption system. The first stage pressure swing adsorption system is based on the adsorbent of the equilibrium adsorption mechanism to separate nitrogen from the pretreated compressed air. Adsorbents based on the equilibrium adsorption mechanism of the primary pressure swing adsorption system include, but are not limited to, combinations of two or more of 5A, 10X, 13X and LiLSX zeolite molecular sieve adsorbents. The nitrogen in the air is selectively adsorbed by the adsorbent bed to produce the primary product gas containing oxygen...

Embodiment 2

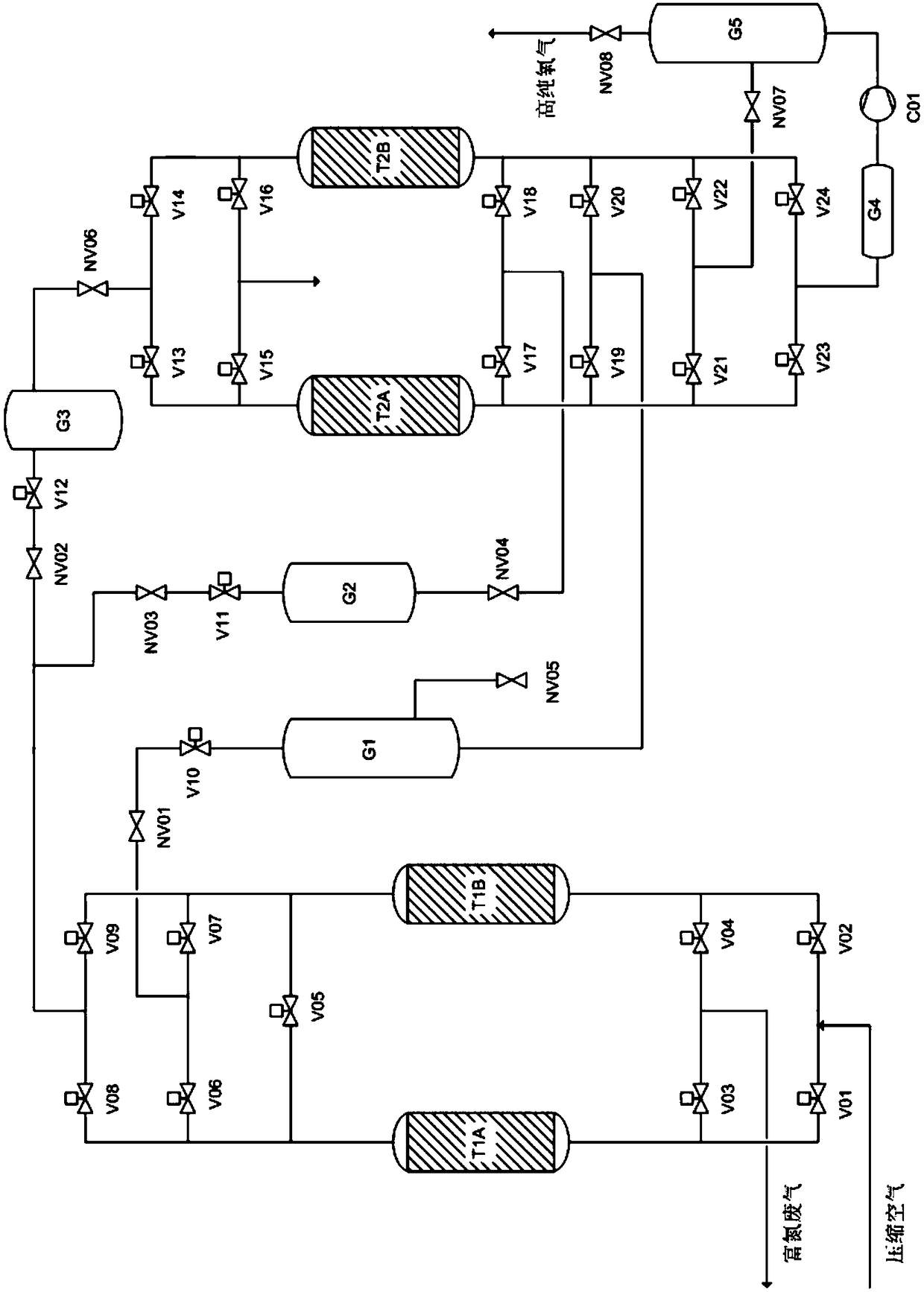

[0060] Such as figure 2 As shown, the two adsorption towers T1A and T1B of the first-stage pressure swing adsorption system are filled with the same zeolite molecular sieve adsorbent of a certain domestic brand, each 300kg, and the two adsorption towers T2A and T2B of the second-stage pressure swing adsorption system are respectively filled with The same carbon molecular sieve adsorbent of a certain domestic brand is 40kg each. The air compressor compresses the air to a gauge pressure of 0.5MPa. The two-stage pressure swing adsorption system operates according to the cycle steps described in Table 1 and Table 2 respectively. The first and sixth stages of the pressure swing adsorption cycle of the second stage pressure swing adsorption system The initial gas production stage of step (see Table 2) flows into the gas storage tank G2 and the collection time is 2 seconds, and the argon-rich tail gas in steps 3 and 8 (see Table 2) The collection time is 8 seconds. The output of t...

Embodiment 3

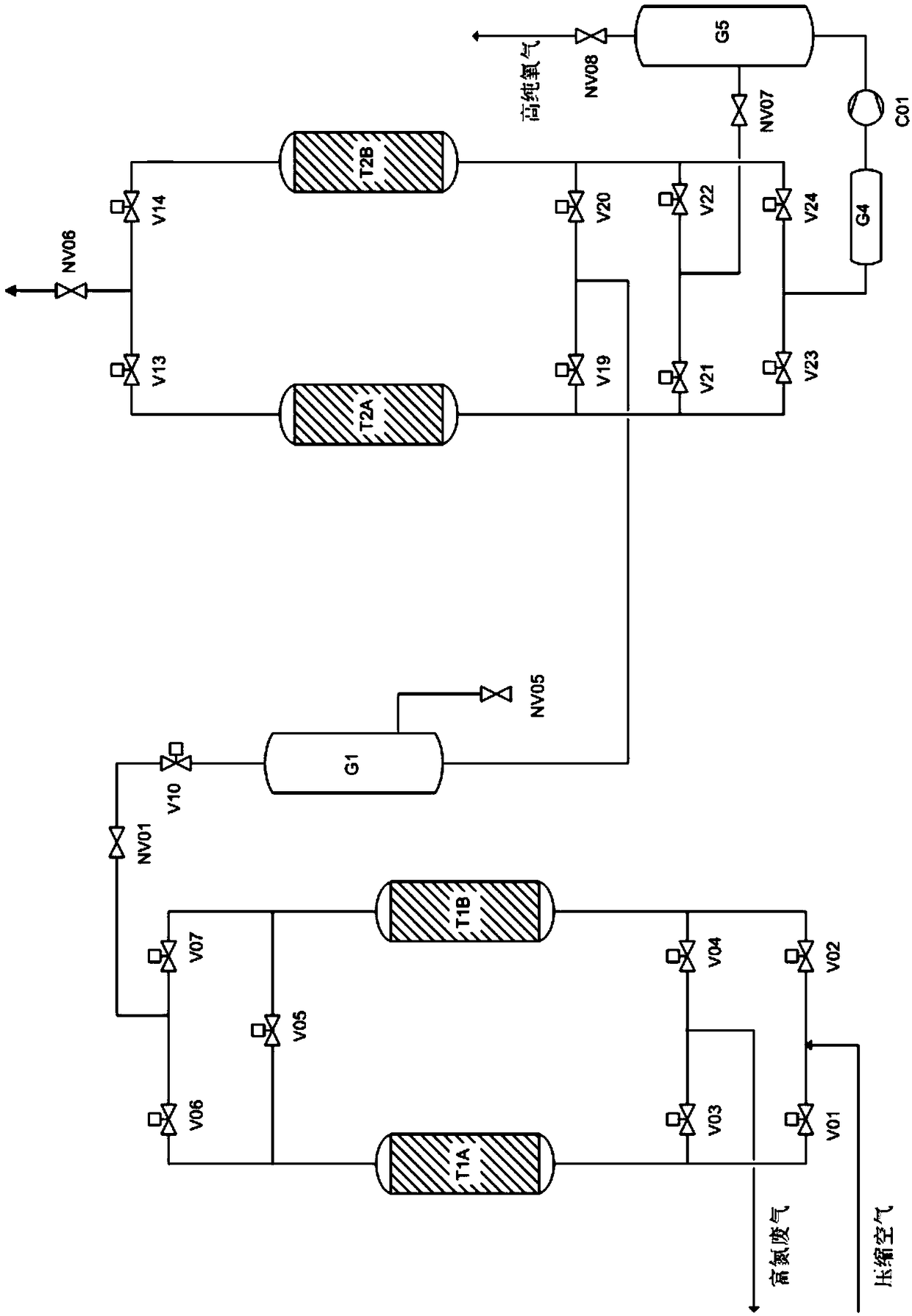

[0062]Compared with Example 2, the steps and operating methods in this example, except the initial gas production stage of steps 1 and 6 (see Table 2) in the pressure swing adsorption cycle of the second stage pressure swing adsorption system, flow into the gas storage tank G2 collection time is shortened to 1 second, and the argon-rich tail gas collection time of the 3rd and 8th step (see Table 2) in the pressure swing adsorption cycle of the second-stage pressure swing adsorption system is all outside 6 seconds, and all the other steps are the same as in Example 2 same. The output of the primary product gas produced by the first stage pressure swing adsorption system is 16.4m3 / h, the oxygen purity is 94.3%, the oxygen recovery rate of the first stage pressure swing adsorption system is 40.1%, and the final stage of the second stage pressure swing adsorption system is The output of product gas is 11.3m3 / h, the oxygen purity is 99.0%, the oxygen recovery rate of the second-sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com