Tool for cutting dry ice and cutterhead provided with same

A tool and cutter head technology, applied in the field of dry ice processing, can solve the problems of bending stress at the cutting edge, high risk of tool chipping, and low cutting edge strength, and achieve the effects of reducing risks, reducing costs, and extending service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to further explain the technical solution of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

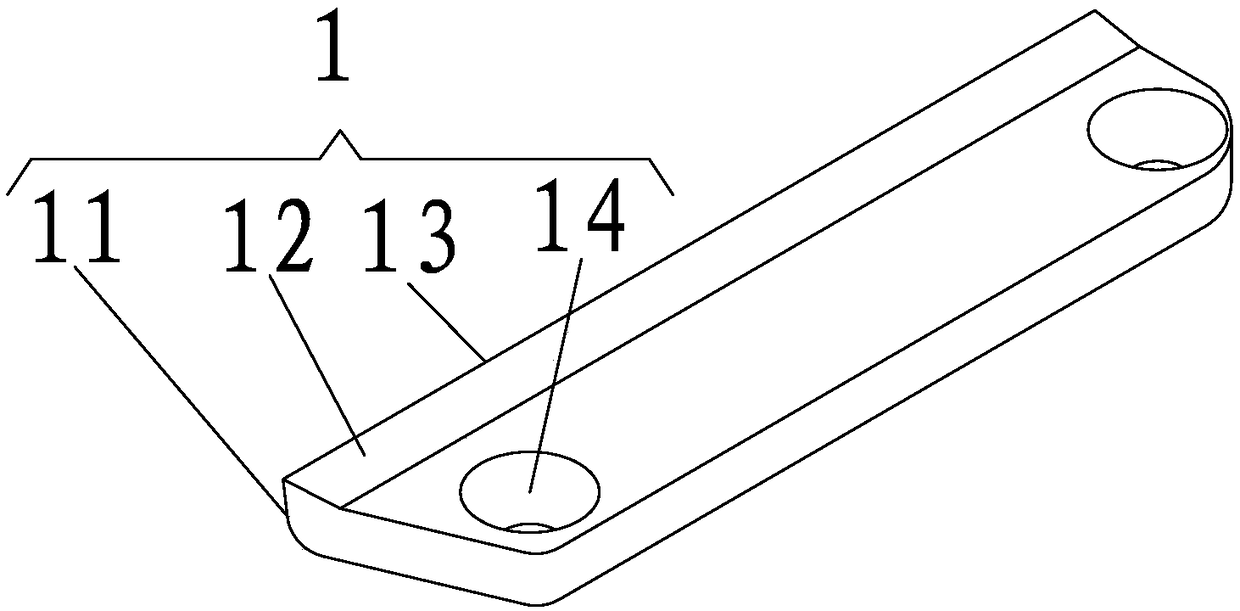

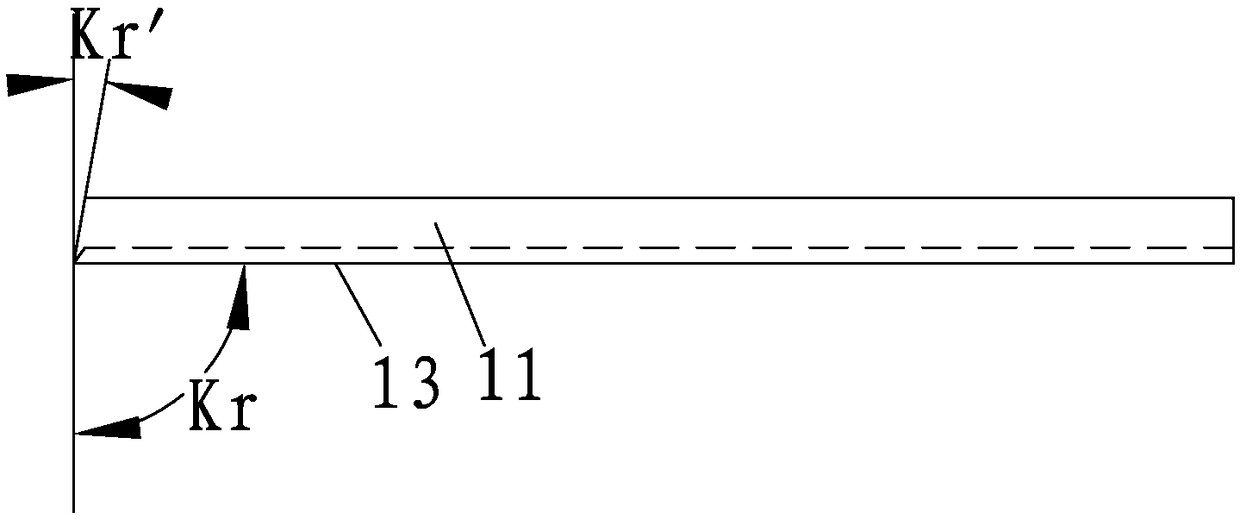

[0045] The present invention is a cutter for cutting dry ice, such as Figures 1 to 6 As shown, a tool body 1 is included, and a rake face 11 , a flank face 12 , and a cutting edge 13 are formed on the tool body 1 .

[0046] The rake face 11 is the conventionally defined rake face 11: the surface on the tool where chips flow out;

[0047] Relief face 12 is conventionally defined flank 12: the face of the tool opposite the transition surface of the workpiece;

[0048] The cutting edge 13 is a conventionally defined cutting edge 13: the intersection line formed by the front and the back, which undertakes the main cutting task in cutting.

[0049] The geometric parameters of the tool include the conventionally defined rake angle γo, relief angle αo, blade inclination ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com