Grinding and processing equipment for graphene material

A grinding process, graphene technology, applied in cocoa, grain processing, chemical instruments and methods, etc., can solve problems such as loud noise, trouble, and inconvenient cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

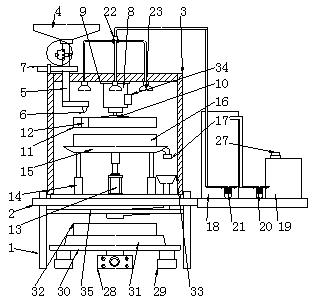

Embodiment Construction

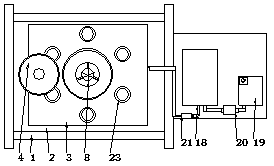

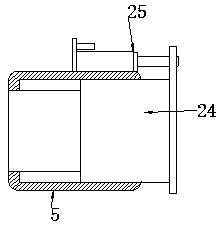

[0038] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-6Shown, a kind of graphene material grinding processing equipment comprises chassis 1, bottom plate 2 and shell 3, and described bottom plate 2 is fixed on the bottom frame 1, and described shell 3 is arranged on the bottom plate 2; Described shell 3 outer walls are provided with There is a feeding unit, and a grinding unit is provided inside the shell 3; a material collection unit is provided between the bottom frame 1, and a cleaning unit is provided on the bottom frame 1; the feeding unit is composed of a feeding mechanism and a flow rate The control mechanism is composed together; the feeding mechanism includes: a collecting cover 4, a feeding pipeline 5 and a feeding nozzle 6; the feeding pipeline 5 is arranged above the shell 3 through a stabilizer 7, and the collecting cover 4 is fixed on 5 ports of the feeding pipeline, the feeding nozzle 6 is connected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com