Preparation method and application of Cu-MOF/carbon dot nanosheet array catalyst

A nanosheet array and catalyst technology, applied in the field of composite materials and catalysis technology, can solve the problems of low reserves, high price, poor stability, etc., and achieve the effects of simple preparation process, many active sites, and easy industrialization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Example 1 A preparation method of Cu-MOF / carbon dot nanosheet array catalyst

[0028] 0.160 g of Cu (NO 3 ) 2 3H 2 O dissolved in 2 mL DMA, 2 mL DMSO, 80 μL H 2 In the mixed solvent that O forms, obtain the copper nitrate solution of clarification;

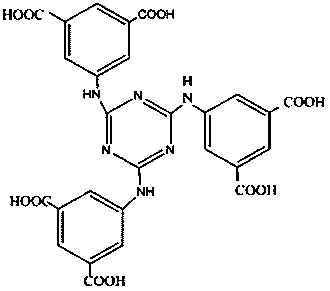

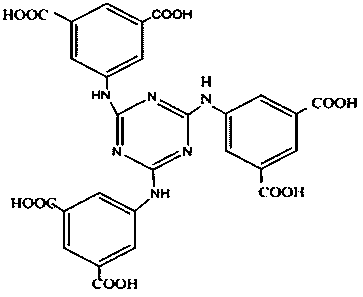

[0029] 0.025 g H 6 L ligand, 0.26g sorbitol and copper nitrate solution are blended, add 0.8 mL HBF 4 , sonicated for 1 min to obtain a clear electrodeposition solution;

[0030] Using a 1.0 cm × 1.0 cm activated copper grid CuF as the working electrode, a platinum sheet as the auxiliary electrode, and a calomel electrode as the reference electrode, in a three-electrode system, a constant potential electrodeposition process was used to prepare Cu-MOF / sorbitol A composite material with nanosheet arrays supported on a copper grid; after washing it with water, it was activated in a 250 W microwave oven for 3 min to prepare an activated Cu-MOF / carbon dot / CuF nanosheet array composite material, namely Cu-MOF / carbon dot nan...

Embodiment 2

[0031] Example 2 A preparation method of Cu-MOF / carbon dot nanosheet array catalyst

[0032] 0.165 g of Cu (NO 3 ) 2 3H 2 O dissolved in 2.5 mL DMA, 2.5 mL DMSO, 100 μL H 2 In the mixed solvent that O forms, obtain the copper nitrate solution of clarification;

[0033] 0.030 g H 6 L ligand, 0.35 g sorbitol and copper nitrate solution were blended, and 0.9 mL HBF was added 4 , sonicated for 2 min to obtain a clear electrodeposition solution;

[0034]Using a 1.0 cm × 1.0 cm activated copper grid CuF as the working electrode, a platinum sheet as the auxiliary electrode, and a calomel electrode as the reference electrode, in a three-electrode system, a constant potential electrodeposition process was used to prepare Cu-MOF / sorbitol A composite material with nanosheet arrays supported on a copper grid; after washing it with water, it was activated in a 250 W microwave oven for 3 min to prepare an activated Cu-MOF / carbon dot / CuF nanosheet array composite material, namely Cu-MO...

Embodiment 3

[0035] Example 3 A preparation method of Cu-MOF / carbon dot nanosheet array catalyst

[0036] 0.170 g of Cu (NO 3 ) 2 3H 2 O dissolved in 3 mL DMA, 3 mL DMSO, 120 μL H 2 In the mixed solvent that O forms, obtain the copper nitrate solution of clarification;

[0037] 0.035 g H 6 L ligand, 0.30g sorbitol and copper nitrate solution were blended, and 1.0 mL HBF was added 4 , ultrasonic 3min, to obtain a clear electrodeposition solution;

[0038] Using a 1.0 cm × 1.0 cm activated copper grid CuF as the working electrode, a platinum sheet as the auxiliary electrode, and a calomel electrode as the reference electrode, in a three-electrode system, a constant potential electrodeposition process was used to prepare Cu-MOF / sorbitol A composite material with nanosheet arrays supported on a copper grid; after washing it with water, it was activated in a 250 W microwave oven for 3 min to prepare an activated Cu-MOF / carbon dot / CuF nanosheet array composite material, namely Cu-MOF / carbo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com