A method for preparing hexavalent chromium ion adsorbent using calla lily as raw material

A technology of calla lilies and raw materials, applied in chemical instruments and methods, adsorbed water/sewage treatment, other chemical processes, etc., can solve the problem of low adsorption capacity of hexavalent chromium ions, etc., and achieve low production cost, few treatment steps, and high efficiency. remove effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

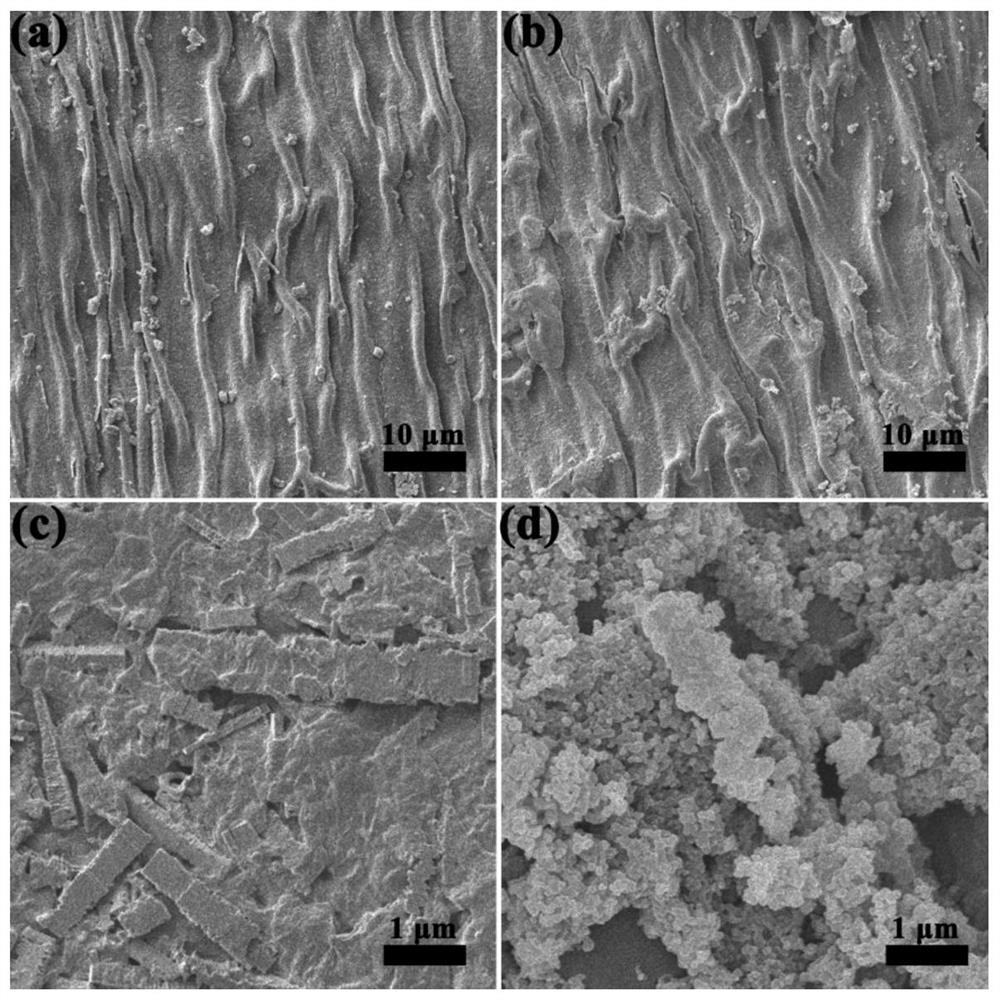

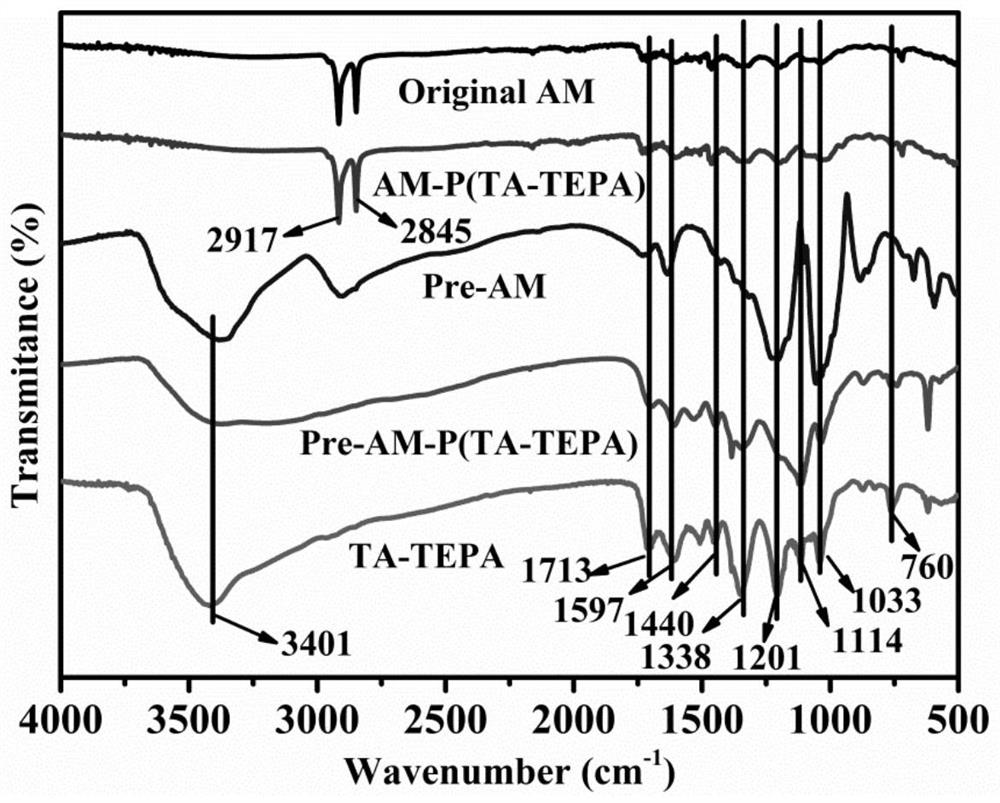

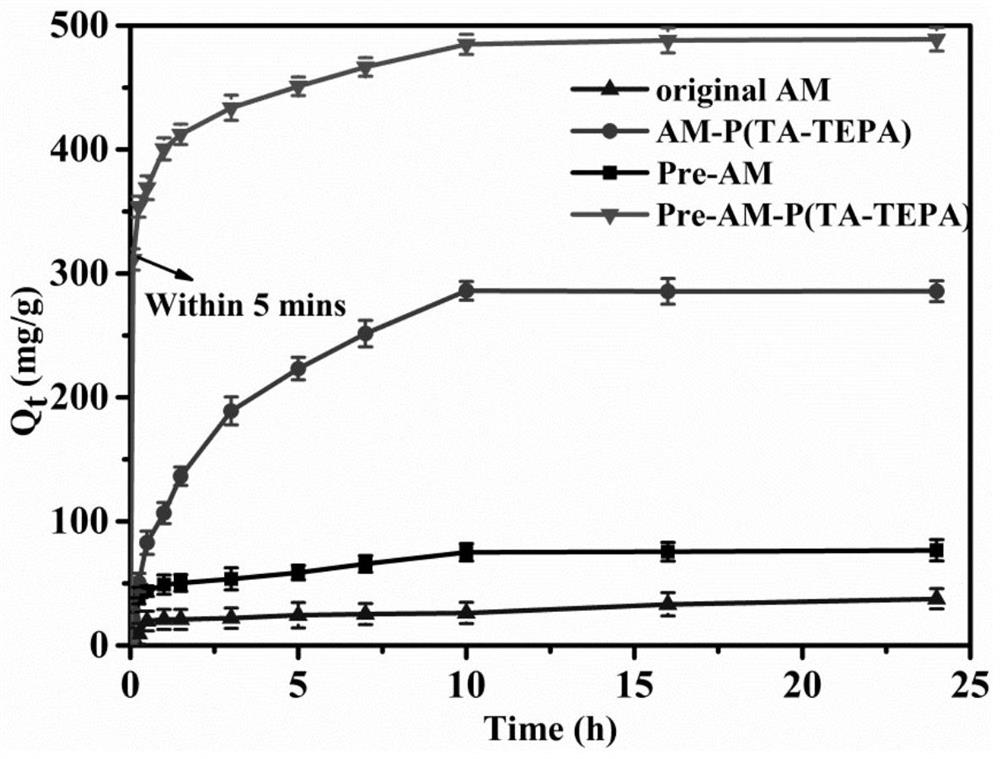

[0044] (1) Cut the calla lily plant into sections, freeze-dry it for later use, and obtain the Original AM;

[0045] (2) Pretreatment of calla lily: boil the freeze-dried calla lily (AM) in distilled water at 100°C for 12 hours to remove soluble organic matter, dry at 80°C for 12 hours to remove excess water, take the dried calla lily and add Stir in 100mL 10% NaOH solution, then place in 100mL 60% H 2 SO 4 Agitation in the solution removes hemicellulose and lignin, and exposes more surface functional groups. Rinse to neutrality with a large amount of distilled water, obtain pretreated calla lily (Pre-AM) after freeze-drying;

[0046] (3) Put 20mg of Pre-AM in tannic acid (TA) aqueous solution, the mass ratio of Pre-AM to TA is 1:1, and the concentration of TA is 4mg / mL. Tetraethylenepentamine (TEPA) was added dropwise under stirring, and the molar ratio of TA to TEPA was 1:3. Rinse with a large amount of distilled water after stirring at room temperature for 24 hours, and...

Embodiment 2

[0048] (1) cut the calla lily plant into sections, freeze-dry and set aside;

[0049] (2) Pretreatment of calla lily: boil the freeze-dried calla lily (AM) in distilled water at 100°C for 12 hours to remove soluble organic matter, dry at 80°C for 12 hours to remove excess water, take the dried calla lily and add Stir in 100mL 10% NaOH solution, then place in 100mL 60% H 2 SO 4 Agitation in the solution removes hemicellulose and lignin, and exposes more surface functional groups. Rinse to neutrality with a large amount of distilled water, obtain pretreated calla lily (Pre-AM) after freeze-drying;

[0050] (3) 20 mg of Pre-AM was placed in tannic acid (TA) aqueous solution, the mass ratio of Pre-AM to TA was 1:1, and the concentration of TA was 2 mg / mL. Tetraethylenepentamine (TEPA) was added dropwise under stirring, and the molar ratio of TA to TEPA was 1:3. Stir at room temperature for 24 hours, rinse with a large amount of distilled water, and freeze-dry to obtain Pre-AM-...

Embodiment 3

[0052] (1) cut the calla lily plant into sections, freeze-dry and set aside;

[0053] (2) Pretreatment of calla lily: boil the freeze-dried calla lily (AM) in distilled water at 100°C for 12 hours to remove soluble organic matter, dry at 80°C for 12 hours to remove excess water, take the dried calla lily and add Stir in 100mL 10% NaOH solution, then place in 100mL 60% H 2 SO 4 Agitation in the solution removes hemicellulose and lignin, and exposes more surface functional groups. Rinse to neutrality with a large amount of distilled water, obtain pretreated calla lily (Pre-AM) after freeze-drying;

[0054] (3) 20 mg of Pre-AM was placed in tannic acid (TA) aqueous solution, the mass ratio of Pre-AM to TA was 1:10 and the concentration of TA was 4 mg / mL. Tetraethylenepentamine (TEPA) was added dropwise under stirring, and the molar ratio of TA to TEPA was 1:1. Stir at room temperature for 24 hours, rinse with a large amount of distilled water, and freeze-dry to obtain Pre-AM-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com