Method for preparing hexavalent chromium ion adsorbent from alocasia macrorrhiza as raw material

A hexavalent chromium ion and adsorbent technology, which is applied in chemical instruments and methods, adsorption water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problem of low adsorption capacity of hexavalent chromium ions and achieve production costs Low, high-efficiency removal effect, the effect of less processing steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

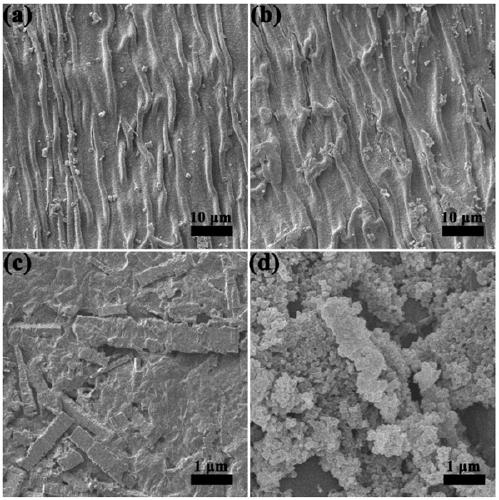

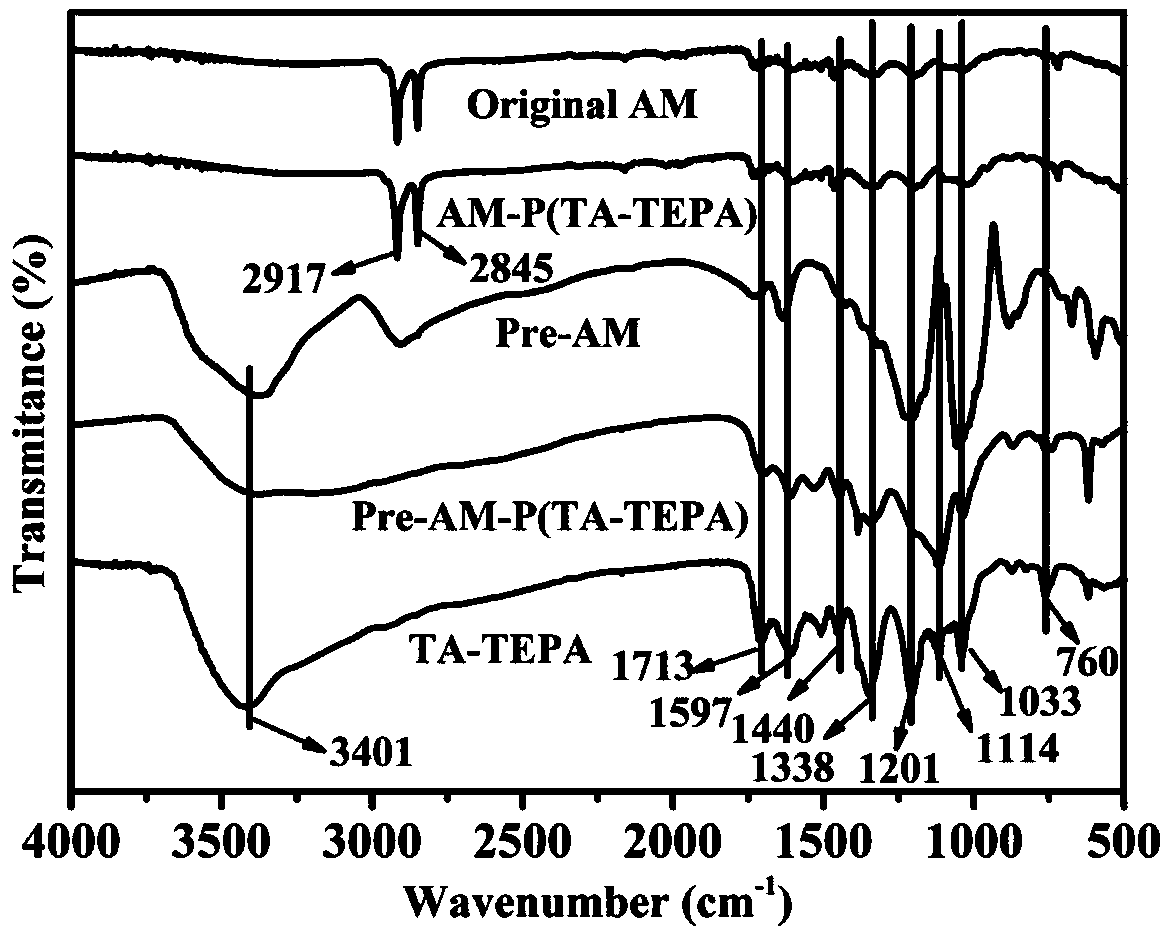

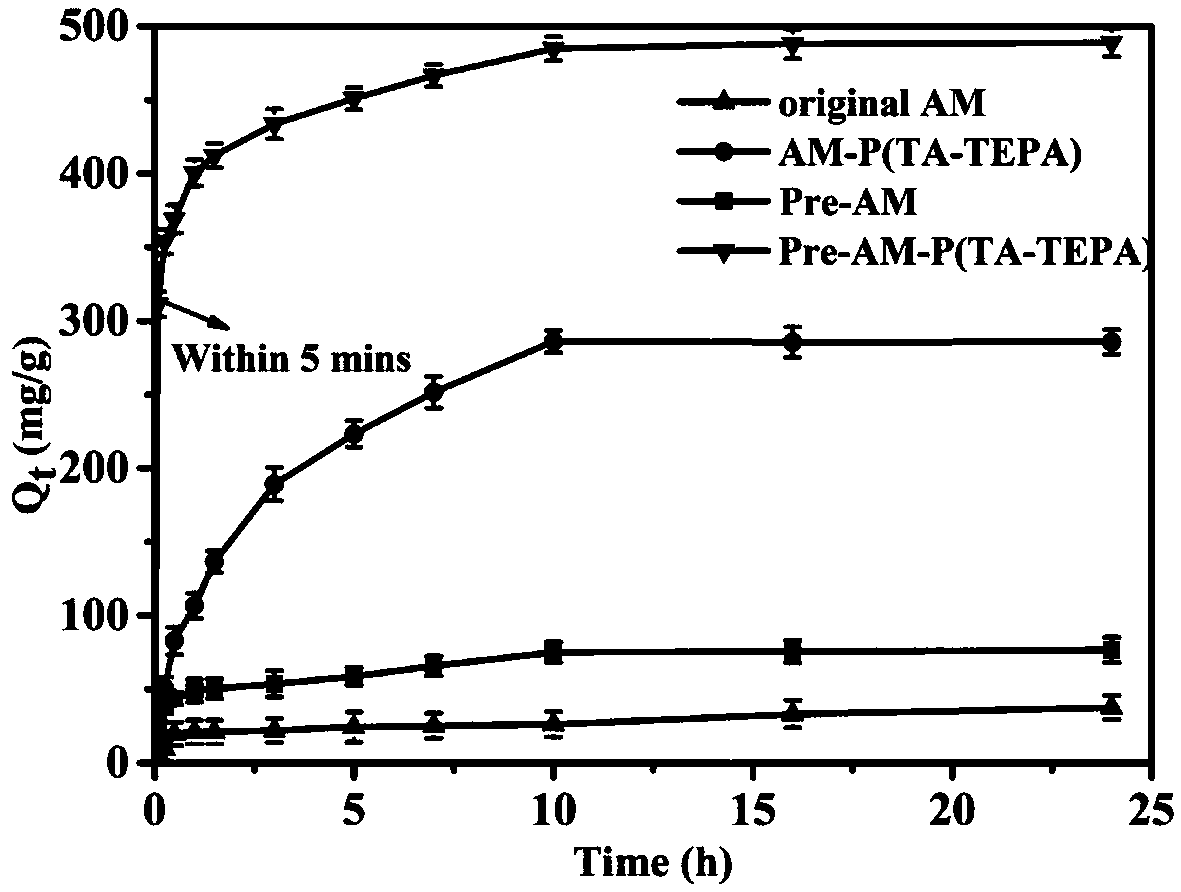

[0044] (1) Cut the calla lily plant into sections, freeze-dry it for later use, and obtain the Original AM;

[0045] (2) Pretreatment of calla lily: boil the freeze-dried calla lily (AM) in distilled water at 100°C for 12 hours to remove soluble organic matter, dry at 80°C for 12 hours to remove excess water, take the dried calla lily and add Stir in 100mL 10% NaOH solution, then place in 100mL 60% H 2 SO 4 Agitation in the solution removes hemicellulose and lignin, and exposes more surface functional groups. Rinse to neutrality with a large amount of distilled water, obtain pretreated calla lily (Pre-AM) after freeze-drying;

[0046] (3) 20 mg of Pre-AM was placed in tannic acid (TA) aqueous solution, the mass ratio of Pre-AM to TA was 1:1, and the concentration of TA was 4 mg / mL. Tetraethylenepentamine (TEPA) was added dropwise under stirring, and the molar ratio of TA to TEPA was 1:3. Rinse with a large amount of distilled water after stirring at room temperature for 24...

Embodiment 2

[0048] (1) cut the calla lily plant into sections, freeze-dry and set aside;

[0049] (2) Pretreatment of calla lily: boil the freeze-dried calla lily (AM) in distilled water at 100°C for 12 hours to remove soluble organic matter, dry at 80°C for 12 hours to remove excess water, take the dried calla lily and add Stir in 100mL 10% NaOH solution, then place in 100mL 60% H 2 SO 4 Agitation in the solution removes hemicellulose and lignin, and exposes more surface functional groups. Rinse to neutrality with a large amount of distilled water, obtain pretreated calla lily (Pre-AM) after freeze-drying;

[0050] (3) 20 mg of Pre-AM was placed in tannic acid (TA) aqueous solution, the mass ratio of Pre-AM to TA was 1:1, and the concentration of TA was 2 mg / mL. Tetraethylenepentamine (TEPA) was added dropwise under stirring, and the molar ratio of TA to TEPA was 1:3. Stir at room temperature for 24 hours, rinse with a large amount of distilled water, and freeze-dry to obtain Pre-AM-...

Embodiment 3

[0052] (1) cut the calla lily plant into sections, freeze-dry and set aside;

[0053] (2) Pretreatment of calla lily: boil the freeze-dried calla lily (AM) in distilled water at 100°C for 12 hours to remove soluble organic matter, dry at 80°C for 12 hours to remove excess water, take the dried calla lily and add Stir in 100mL 10% NaOH solution, then place in 100mL 60% H 2 SO 4 Agitation in the solution removes hemicellulose and lignin, and exposes more surface functional groups. Rinse to neutrality with a large amount of distilled water, obtain pretreated calla lily (Pre-AM) after freeze-drying;

[0054] (3) 20 mg of Pre-AM was placed in tannic acid (TA) aqueous solution, the mass ratio of Pre-AM to TA was 1:10 and the concentration of TA was 4 mg / mL. Tetraethylenepentamine (TEPA) was added dropwise under stirring, and the molar ratio of TA to TEPA was 1:1. Stir at room temperature for 24 hours, rinse with a large amount of distilled water, and freeze-dry to obtain Pre-AM-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com