A kind of sulfonate type fluorosilicon anionic surfactant and preparation method thereof

A surfactant and sulfonate-type technology, applied in the field of sulfonate-type fluorosilicon anionic surfactants and their preparation, can solve environmental and human health hazards, perfluorooctane sulfonic acid and perfluorooctanoic acid are difficult to hydrolyze, light Solution or microbial degradation and other problems, to achieve the effect of expanding the application range, good water solubility and biodegradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

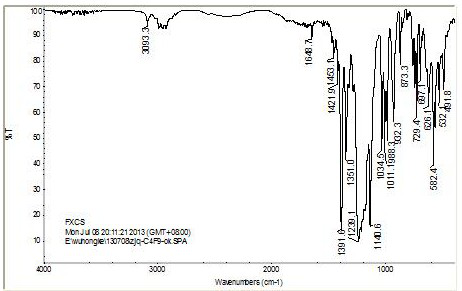

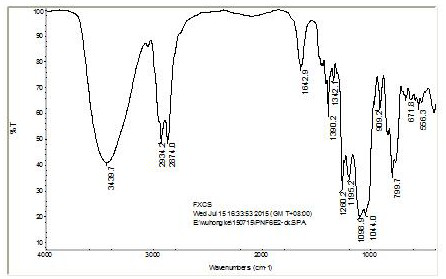

[0030] A kind of preparation method of sulfonate type fluorosilicon anionic surfactant, such as Figure 1-4 Shown, this preparation method comprises the following steps:

[0031](1) add 20mL ethyl acetate and 1.78gN-methallylamine in the 50mL four-neck flask that agitator, thermometer, dropping funnel and reflux condenser are housed, described reflux condenser is equipped with anhydrous CaCl Drying tube , the concentration of the 1.78g N-methylallylamine is 0.025mol, and 4.02g perfluorohexylsulfonyl fluoride is gradually added dropwise at room temperature, the concentration of the 4.02g perfluorohexylsulfonyl fluoride is 0.01mol, and it is controlled to drip for 30 minutes After the addition is complete, continue to stir and react at 40°C for 2 h; after stopping the reaction, pour the reaction solution into 100 mL of water, remove the light yellow liquid in the lower layer after layering, and wash with 50 mL of 5% HCl aqueous solution, 30 mL of saturated NaCO 3 aqueous soluti...

Embodiment 1

[0038] A kind of preparation method based on sulfonate type fluorosilicon anionic surfactant of the present embodiment comprises the following steps:

[0039] (1)C 6 f 13 SO 2 N(CH 3 )CH 2 CH=CH 2 Synthesis

[0040] Add 20 mL of ethyl acetate and 1.78 g (0.025 mol) of N-methallylamine to a 50 mL four-necked flask equipped with a stirrer, a thermometer, a dropping funnel, and a reflux condenser (an anhydrous CaCl2 drying tube is installed on the top), at room temperature Gradually add 4.02g (0.01mol) of perfluorohexylsulfonyl fluoride dropwise, control the dropwise addition for about 30min, and continue to stir and react at 40°C for 2h. After stopping the reaction, pour the reaction solution into 100mL water, remove the light yellow liquid in the lower layer after layering, and wash with 50mL 5% HCl aqueous solution, 30mL saturated NaCO 3 The aqueous solution was washed with 2×30 mL of water, and dried over anhydrous sodium sulfate to obtain a light yellow transparent li...

Embodiment 2

[0064] This embodiment is the same as Embodiment 1, the difference is:

[0065] (2) Synthesis of hydrosilylation products

[0066] Mix 2.5g high hydrogen silicone oil, 1.08g C 6 f 13 SO 2 N(CH 3 )CH 2 CH=CH 2 Add 20mL of toluene into a 100mL three-necked round-bottomed flask, then add Karstedt catalyst with a concentration of 16.123g / L, connect a condensing device and a thermometer, stir magnetically, and heat the oil bath to 90°C; when the hydrosilylation conversion rate reaches 6% When, add 4.40g allyl glycidyl ether, continue to react until the hydrosilylation reaction conversion rate is substantially constant.

[0067] The amount of silicon hydrogen substance in the high hydrogen-containing silicone oil in the reaction system is 40.85mmol, C 6 f 13 SO 2 N(CH 3 )CH 2 CH=CH 2 The amount of carbon-carbon double bond in allyl glycidyl ether is 2.45mmol and 38.40mmol respectively, and the ratio of the amount of the three substances is 10:0.6:9.4. It can be seen fro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

| critical micelle concentration (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com