Mobile phone shell assembly, mobile phone, and mobile phone production method

A mobile phone shell and component technology, applied in electrical components, telephone structure, telephone communication, etc., can solve problems such as hand scraping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

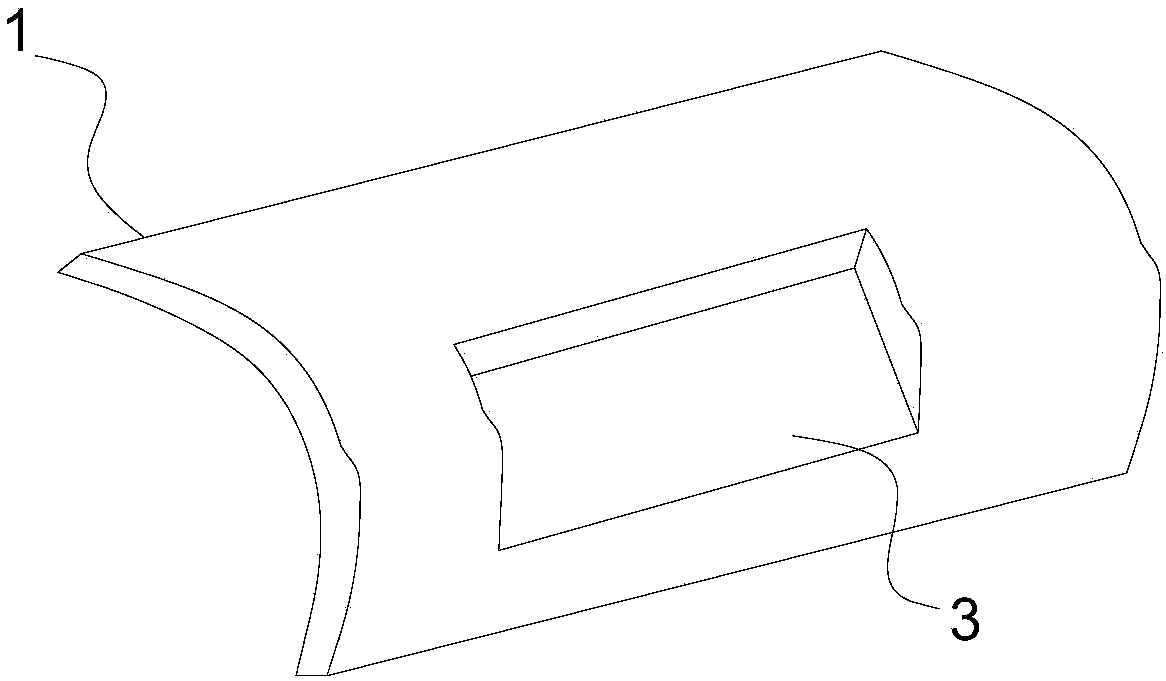

[0030] combined with Figure 1-3 As shown, this embodiment provides a mobile phone case assembly, including a battery cover and a card tray, such as figure 1 As shown, the battery cover of this embodiment includes a back cover (not shown in the figure) and four side walls connected around the back cover (the accompanying drawings of this embodiment only show one side wall), the four side walls One of the side walls (that is, the side wall in the figure) is provided with a through hole into which the card tray can be inserted. It can be seen from the figure that the cross section of the side wall is arc-shaped.

[0031] The back cover described in this embodiment is the back shell of the mobile phone, and the four side walls are also the four outer shells of the mobile phone. The back cover and the side walls can be integrally connected or have a split structure. Of course, the battery cover of the mobile phone Specific features such as specific structures and materials are co...

Embodiment 2

[0038] The second object of the present invention is to provide a mobile phone (not shown in the figure), which has the mobile phone case assembly as described in the first embodiment.

Embodiment 3

[0040] This embodiment provides a production method of a mobile phone, specifically the processing steps in the production of the battery cover and the tray.

[0041] Specifically, the method includes:

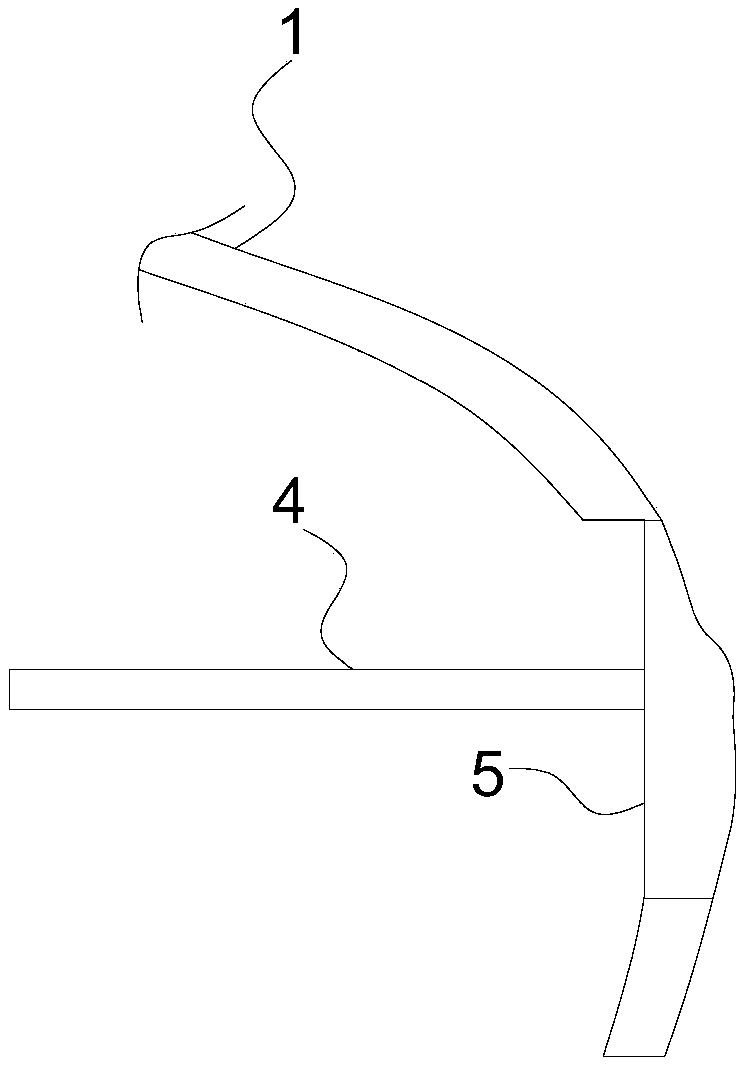

[0042] Processing of the battery cover: IMT process is performed on the outer surface of the battery cover to form such as Figure 4 The side wall structure shown; then the film on the battery cover after treatment is torn off, and the outer surface of one of the side walls of the battery cover after the film is torn off forms a first area and a second area with a height difference, and The junction of the first area and the second area is arranged along the length direction of the side wall, forming such as Figure 5 The structure shown, and then grind the junction of the first area and the second area to form a Figure 6 structure shown.

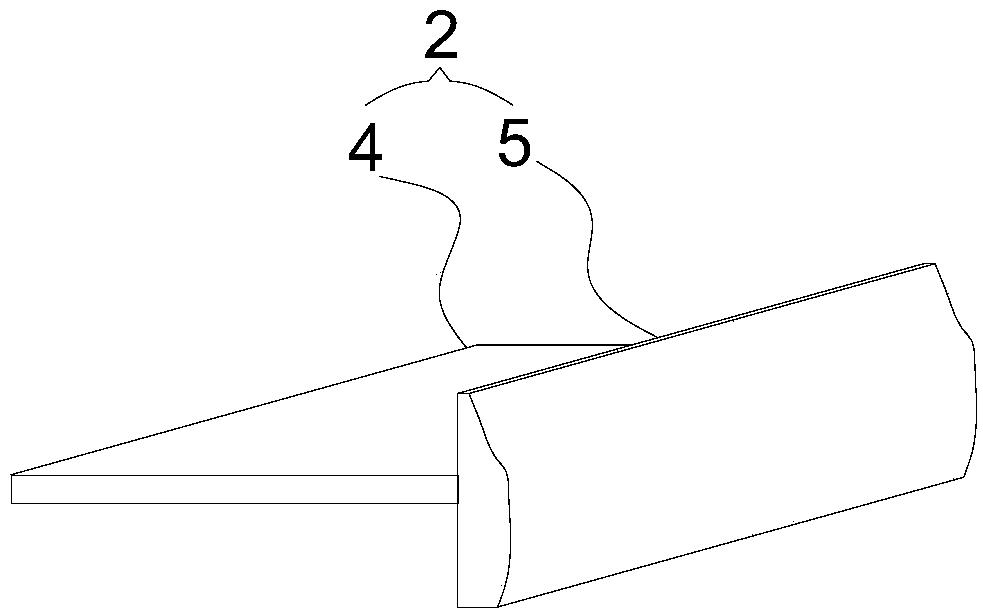

[0043] Processing of Cato: The outer surface of the end cover of Cato is pre-processed into a third area and a fourth area with a heig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com