Integral cavity division partition plate and carbon tank thereof

An integral, sub-chamber technology, applied in the direction of adding non-fuel materials, engine components, machines/engines, etc. Achieve the effects of increasing adsorption and desorption efficiency, reducing airflow temperature, and prolonging the passing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1 A kind of integral compartment partition

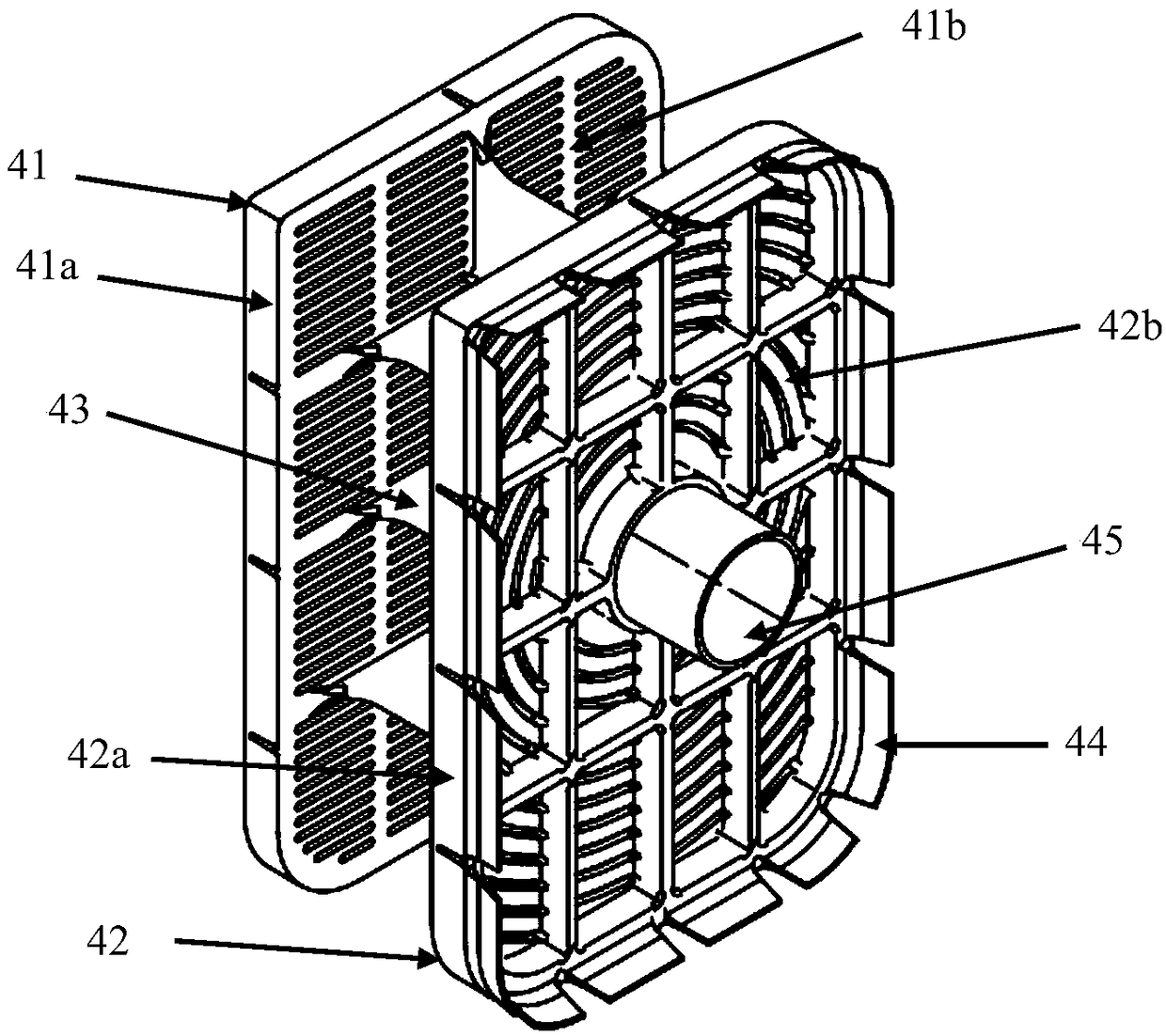

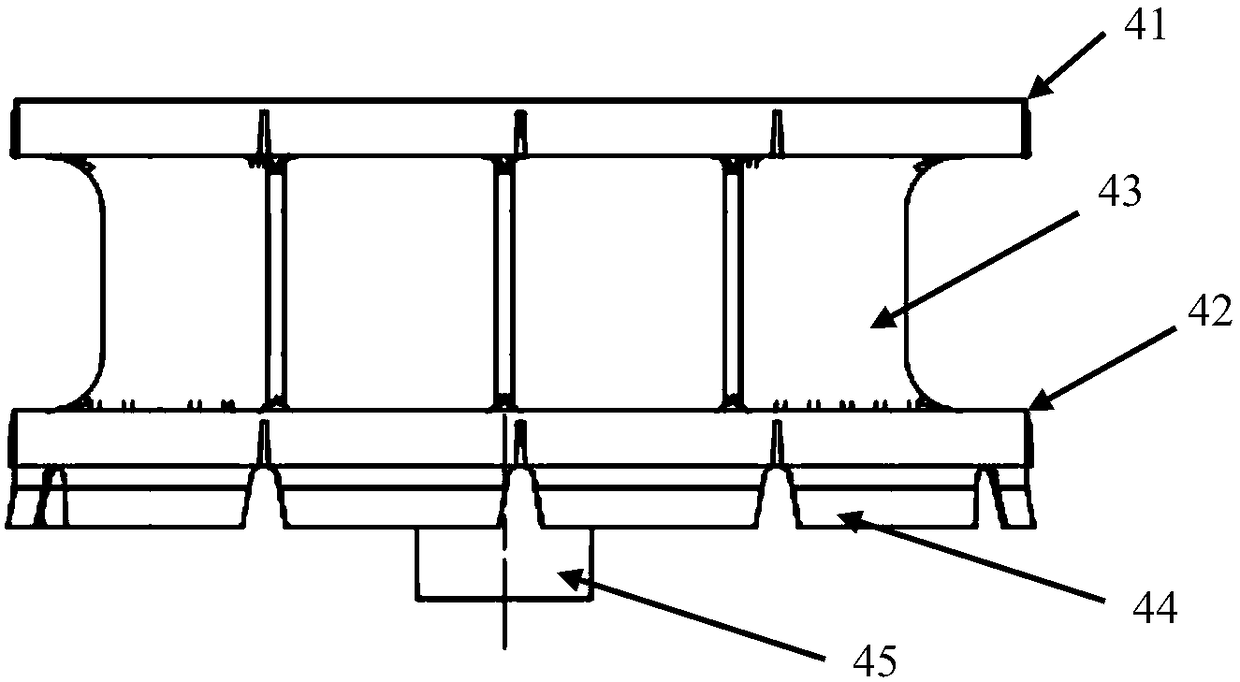

[0029] Such as Figure 1-3 The one-piece compartment partition shown is made of engineering plastics through one-time injection molding, and it includes an upper support plate 41 and a lower support plate 42, as well as four reinforcing rib plates between the upper support plate 41 and the lower support plate 42 43. The four reinforcing rib plates 43 are all "I" character plates, interlaced to form a "Feng" character structure.

[0030] The upper support plate 41 is made up of an upper base plate 41a and an upper surface layer 41b, the upper base plate 41a is a grid plate, the thickness of the grid plate is about 2mm, and the side of the grid plate facing the lower support plate 42 is provided with a thickness of about The upper surface layer 41b is 1.5mm, and the upper surface layer 41b is provided with a plurality of strip-shaped slits arranged in a matrix, and the slit width of each strip-shaped slit is about...

Embodiment 2

[0034] Embodiment 2 A kind of charcoal canister comprising an integral compartment partition

[0035] Such as Figure 4 As shown, this embodiment is a typical carbon canister of three different types and volumes of carbon powder. The upper end cover 140 and the canister shell 10 are welded together to form a liquid collection chamber, which can accommodate a certain volume of liquid fuel overflowing from the fuel tank, so as to prevent the fuel from directly entering into the carbon powder C 110 to cause functional failure.

[0036]The interior of the canister shell 10 is provided with a vertical partition, which divides the space in the shell 10 into chamber I and chamber II which are arranged side by side. The top of the chamber I is connected with an adsorption port T and a desorption port P, and carbon powder C 110 is housed inside; the top of the chamber II is connected with an air port A, and an integral compartment partition 40 is installed inside, Carbon powder A 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com