Technological method for regenerative recycling treatment of waste mineral oil

A technology of waste mineral oil and renewable resources, applied in the direction of lubricating compositions, etc., can solve the problems affecting the continuous and stable operation of the system, the ceramic filter is easy to block, and cannot be fully utilized, so as to reduce the amount of residue generated and prevent leachate The precipitation and the effect of reducing the amount of waste residue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

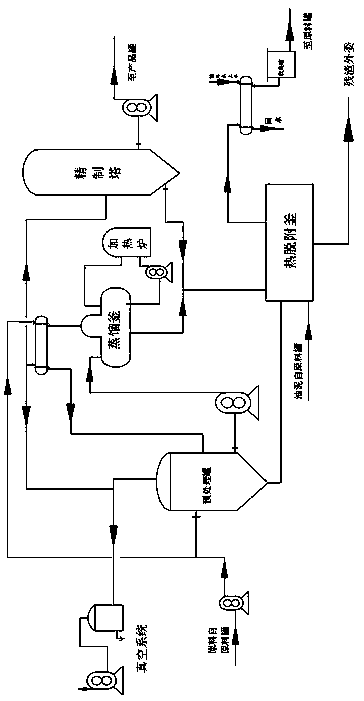

Image

Examples

Embodiment 1

[0025] A process method for recycling waste mineral oil, the steps are as follows:

[0026] Taking the waste oil and sludge produced by a refinery as an example, the basic composition of the waste oil is 5-8% moisture, 0.3-0.6% ash, 1.1-2% mechanical impurities, and a density of 0.89kg / cm 3 ; The oil sludge is the bottom sludge of the refinery tank, with an oil content of 20-30%, and the rest is water and mechanical impurities. The specific disposal process is as follows:

[0027] 1. Pump the waste lubricating oil in the raw material tank to the pretreatment tank, settle and dehydrate it, and set up a vacuum system on the top of the pretreatment tank. The vacuum degree is 50 kPa, and the temperature at the top of the tower is 75 ° C. Moisture;

[0028] 2. The pretreated raw materials are discharged from the middle and lower part, and then sent to the distillation tower through the pump and the double-tube filter in turn. The filtration accuracy of the double-tube filter is b...

Embodiment 2

[0034] A process method for recycling waste mineral oil, the steps are as follows:

[0035] Taking the waste oil and sludge produced by a refinery as an example, the basic composition of the waste oil is 5-8% moisture, 0.3-0.6% ash, 1.1-2% mechanical impurities, and a density of 0.89kg / cm 3 ; The oil sludge is the bottom sludge of the refinery tank, with an oil content of 20-30%, and the rest is water and mechanical impurities. The specific disposal process is as follows:

[0036] (1) Pump the waste lubricating oil in the raw material tank to the pretreatment tank, settle and dehydrate it, set up a vacuum system on the top of the pretreatment tank, the vacuum degree is 20 kPa, the temperature at the top of the tower is 60 ℃, and the low boiling matter is separated and moisture;

[0037] (2) The pretreated raw materials are discharged from the middle and lower parts, and then sent to the distillation tower through the pump and the double-cylinder filter in turn. The filtratio...

Embodiment 3

[0041] A process method for recycling waste mineral oil, the steps are as follows:

[0042] Taking the waste oil and sludge produced by a refinery as an example, the basic composition of the waste oil is 5-8% moisture, 0.3-0.6% ash, 1.1-2% mechanical impurities, and a density of 0.89kg / cm 3; The oil sludge is the bottom sludge of the refinery tank, with an oil content of 20-30%, and the rest is water and mechanical impurities. The specific disposal process is as follows:

[0043] (1) Pump the waste lubricating oil in the raw material tank to the pretreatment tank, settle and dehydrate it, set up a vacuum system on the top of the pretreatment tank, the vacuum degree is 100 kPa, the temperature at the top of the tower is 90 ℃, and the low boiling matter is separated and moisture;

[0044] (2) The pretreated raw materials are discharged from the middle and lower parts, and then sent to the distillation tower through the pump and the double-cylinder filter in turn. The filtratio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com