Solvent-free two-component polyurethane waterproof coating with flame retarding and smoke inhibiting effects

A two-component polyurethane and waterproof coating technology, used in polyurea/polyurethane coatings, fire-retardant coatings, coatings, etc., can solve problems such as life safety hazards and hinder escape, and achieve excellent workability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

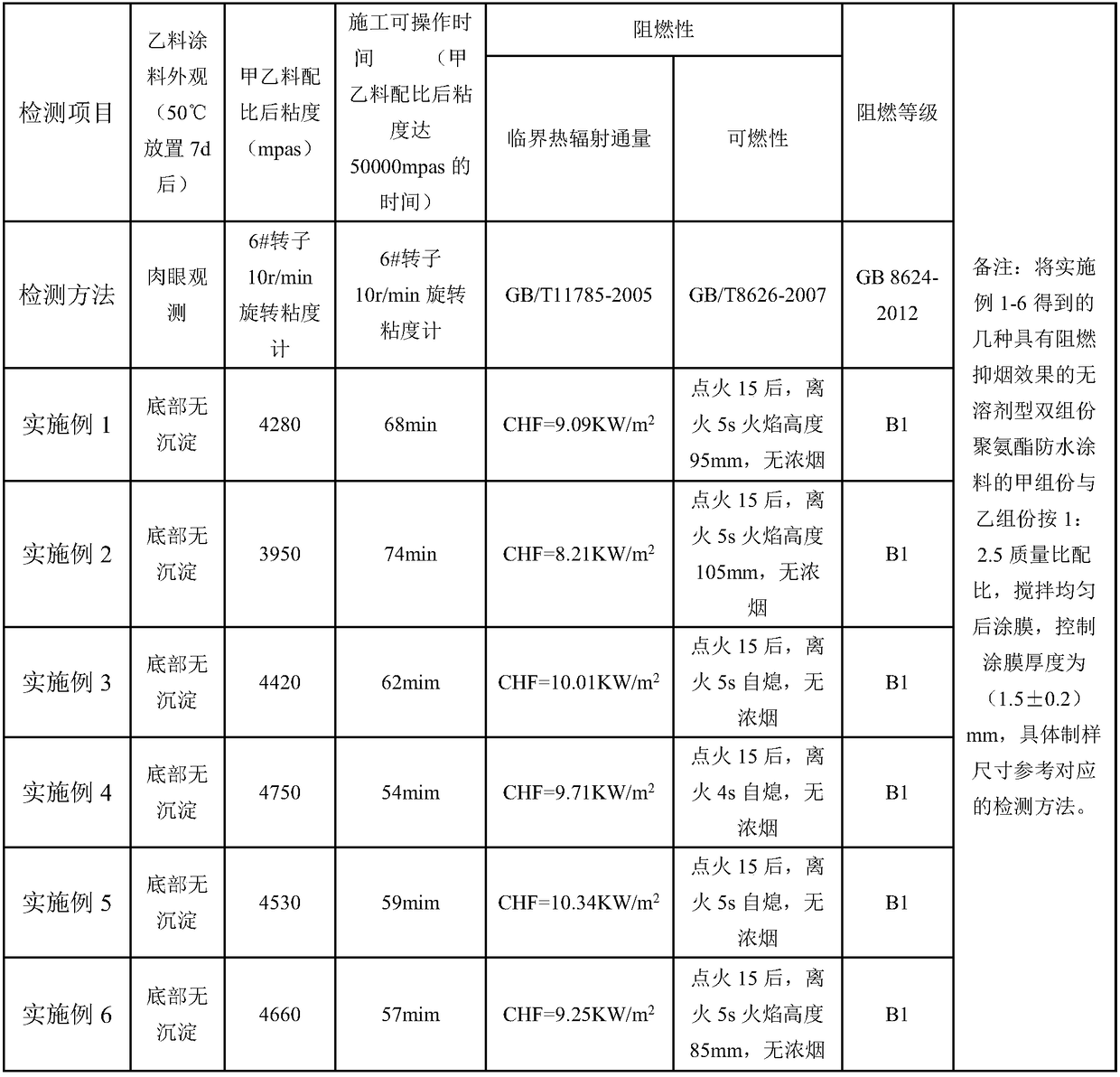

Examples

Embodiment 1

[0022] The preparation of component A of this example 1 (by mass parts) is as follows: mix 63 parts of polyether N220 and 18 parts of polyether N330 evenly, heat up to 90-100°C while stirring, and maintain a vacuum degree of -0.08-0.09MPa Dehydrate for 1 hour, use a Karl Fischer moisture analyzer to detect that the moisture content is less than 0.05%, and then cool down to 70-75°C (if the moisture content is not less than 0.05%, continue dehydration until the moisture content is less than 0.05%, then proceed to the next step), slowly add 24 After reacting at 80-85°C for 2-3 hours, add 20 parts of chlorinated paraffin 52 whose moisture content has been detected to be less than 0.05%, stir for 0.5h, cool down to 60°C and discharge to obtain component A ;

[0023] The preparation of component B of Example 1 (by mass) is as follows: add 90 parts of polyether 330N, 80 parts of chlorinated paraffin 52, 45 parts of rubber filler oil, and 3.8 parts of DISPERBYK108 into a multifunction...

Embodiment 2

[0025] The preparation of component A of this Example 2 (by mass parts) is as follows: Mix 63 parts of polyether N220 and 18 parts of polyether N330 evenly, heat up to 90-100°C while stirring, and maintain a vacuum of -0.08-0.09MPa Dehydrate for 1 hour, use a Karl Fischer moisture analyzer to detect that the moisture content is less than 0.05%, and then cool down to 70-75°C (if the moisture content is not less than 0.05%, continue dehydration until the moisture content is less than 0.05%, then proceed to the next step), slowly add 24 After reacting at 80-85°C for 2-3 hours, add 20 parts of chlorinated paraffin 52 whose moisture content has been detected to be less than 0.05%, stir for 0.5h, cool down to 60°C and discharge to obtain component A ;

[0026]The preparation of component B in Example 2 (in parts by mass) is as follows: add 90 parts of polyether 330N, 90 parts of naphthenic oil, 50 parts of aromatic oil, and 4.5 parts of DISPERBYK107 into a multifunctional powerful d...

Embodiment 3

[0028] The preparation of component A of Example 3 (in parts by mass) is as follows: mix 63 parts of polyether N220 and 18 parts of polyether N330 evenly, heat up to 90-100°C while stirring, and maintain a vacuum of -0.08-0.09MPa Dehydrate for 1 hour, use a Karl Fischer moisture analyzer to detect that the moisture content is less than 0.05%, then cool down to 70-75°C (if the moisture content is not less than 0.05%, continue dehydration until the moisture content is less than 0.05%, and then proceed to the next step), slowly add 24 After reacting at 80-85°C for 2-3 hours, add 20 parts of chlorinated paraffin 52 whose moisture content has been detected to be less than 0.05%, stir for 0.5h, cool down to 60°C and discharge to obtain component A ;

[0029] The preparation of component B of Example 3 (by mass parts) is as follows: add 90 parts of polyether 330N, 85 parts of epoxy soybean oil, 50 parts of rubber filler oil, and 4.3 parts of DISPERBYK111 into a multifunctional powerf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com