Special additive for wear-resistant hydraulic oil with excellent thermal stability and preparation method thereof

A technology of anti-wear hydraulic oil and additives, which is applied in the field of hydraulic oil, can solve the problems of not meeting the requirements of thermal stability, failing to meet the requirements of hydraulic oil, and poor thermal stability of hydraulic oil, so as to improve thermal stability and reduce Post-waste treatment, thermal stability improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

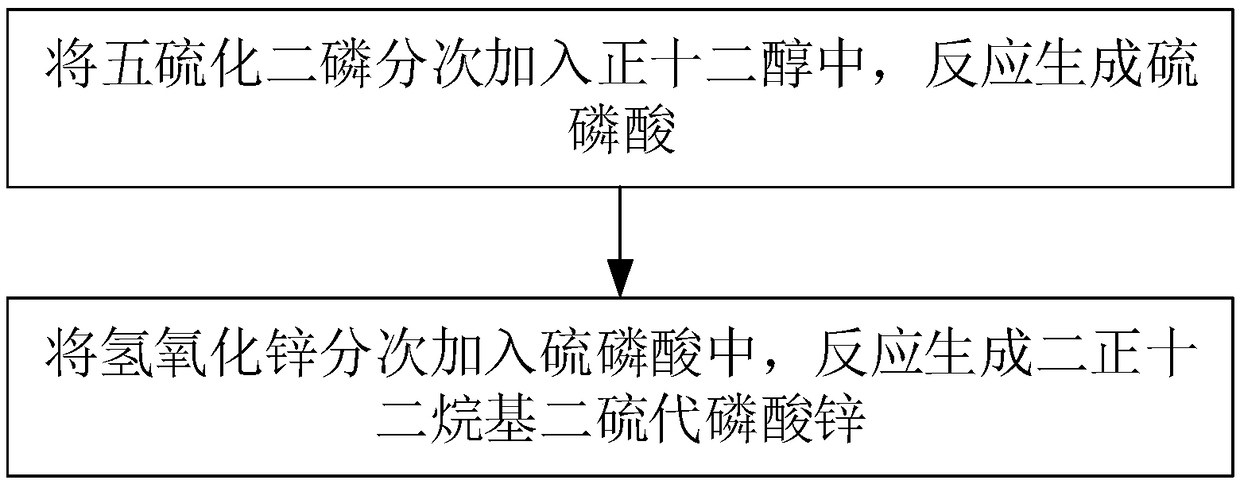

[0029] Such as figure 1 As shown, the present invention also provides a preparation method of a special additive for anti-wear hydraulic oil with excellent thermal stability, comprising:

[0030] Step 1, adding phosphorus pentasulfide in n-dodecyl alcohol in stages, and reacting to generate sulfuric acid:

[0031] Add the weighed n-dodecyl alcohol (n-dodecyl alcohol is added to the excess of 0.5% of the standard reaction mole to observe the stop time of the reaction) in the four-necked flask, and connect the tail gas treatment device, and heat up to 80 ° C to 90 ° C. ℃, preferably warming up to 85 ℃, with the weighed phosphorus pentasulfide, the P content of phosphorus pentasulfide is 28.11~28.2%, preferably the P content of phosphorus pentasulfide is 28.15~28.2%; The time interval for adding phosphorus pentasulfide is 15 minutes, and when adding phosphorus pentasulfide, ensure that the system temperature does not exceed 95°C. After adding phosphorus pentasulfide, raise the s...

Embodiment 1

[0035] Step 1, add weighed n-dodecyl alcohol (0.5% in excess) in the four-necked flask, and connect the tail gas treatment device, heat up to 85°C, weigh 122.0 g of phosphorus pentasulfide solids with a P content of 28.15%, and divide into 4 Add in n-dodecyl alcohol on average every time, the time interval for each addition of phosphorus pentasulfide is 15 minutes, and ensure that the system temperature does not exceed 95°C. After adding phosphorus pentasulfide, raise the system temperature to 110°C and keep it for 7 hours. Stop when the solid of phosphorus pentasulfide no longer decreases. Reaction, then suction filtration while hot, after the reaction finishes, detect qualified sulfuric acid phosphoric acid for subsequent use;

[0036] Step 2, add 230.0g phosphoric acid sulfuric acid in the four-necked flask that is equipped with condenser tube, be warming up to 75 ℃, 29.2g zinc hydroxide (excessive 20%) is added into phosphoric acid sulfuric acid in 4 times on average, the t...

Embodiment 2

[0038]It is 27.9-28.1% phosphorus pentasulfide (the P content of the phosphorus pentasulfide used in the lubricating oil additive industry is generally 27.9-28.1%) to change phosphorus pentasulfide into P content in embodiment 1, remaining part remains the same with embodiment 1, makes pale yellow The transparent finished product is recorded as: product 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com