Tetramethyl ammonium hydroxide wastewater treatment device

A technology for tetramethylammonium hydroxide and waste water treatment, applied in the field of waste water treatment, can solve the problems of high treatment cost and outbound transportation cost, pollution of ecological water bodies, and high cost of flash evaporation, and achieves easy popularization and use, low cost, The effect of easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

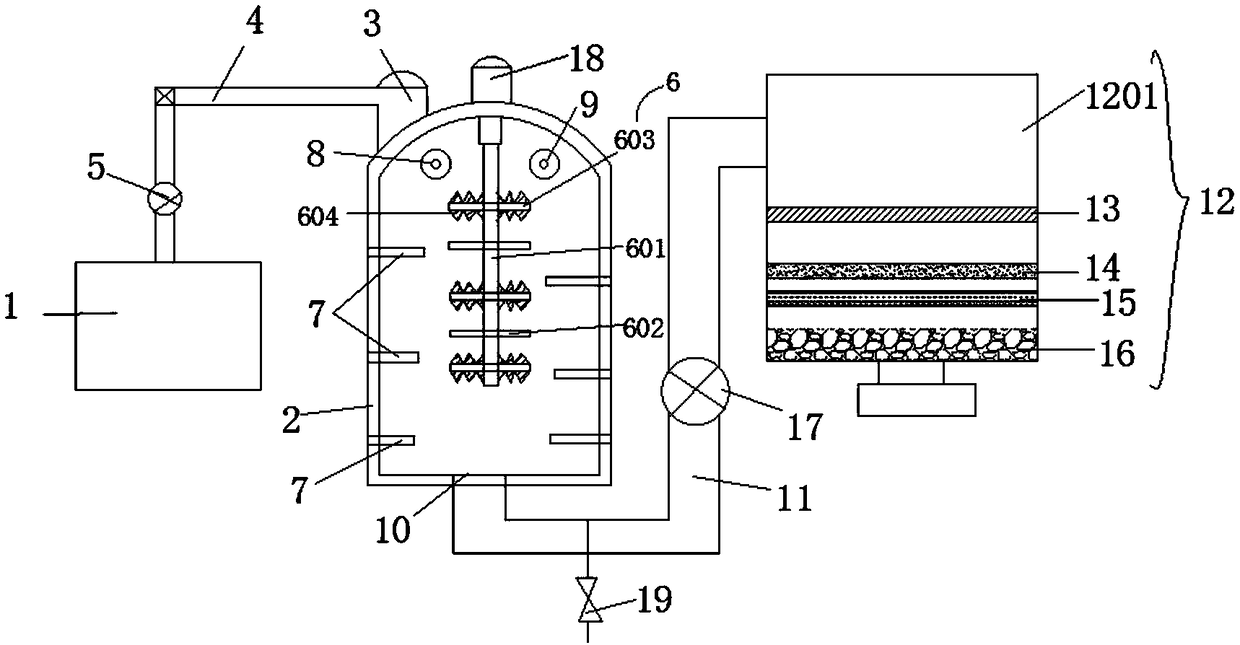

[0017] Example 1: see figure 1 Now, a tetramethylammonium hydroxide wastewater treatment device provided by the present invention will be described, including a reservoir 1, which is connected to the water inlet 3 of the neutralization reactor 2 through a water delivery pipe 4, and the delivery The pipe of the water pipe 4 is provided with a water delivery pump 5, and a stirring assembly 6 is installed inside the body of the neutralization reaction kettle 2. The stirring assembly 6 includes a stirring shaft 601, and the shaft body of the stirring shaft 601 is upward A number of stirring crossbars 602 and stirring spoiler rods 603 are sequentially installed underneath. The rod body of the stirring spoiler rod 603 is equipped with spoiler teeth 604, and the inner sides of the neutralization reactor 2 are equipped with baffles. 7. The upper end of the neutralization reactor 2 is provided with an acid inlet 8 and a lye inlet 9, and the lower end of the neutralization reactor 2 is p...

Embodiment 2

[0018] Example 2: see figure 1 As an improvement of the present invention, the filter medium 16 can be one of quartz sand, garnet, anthracite and activated carbon.

Embodiment 3

[0019] Example 3: See figure 1 As an improvement of the present invention, an upper water pump 17 is installed on the body of the upper water pipe 11.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com