Anti-separation ring rolling mechanism used for communication cable machining and production

A technology of communication optical cable and winding mechanism, which is applied in the directions of conveying filamentous materials, thin material processing, transportation and packaging, etc., can solve the problems of bending and twisting of communication optical cables, rise of communication cables, waste of resources, etc., and save production. resources, improve product quality, and ensure the effect of aesthetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

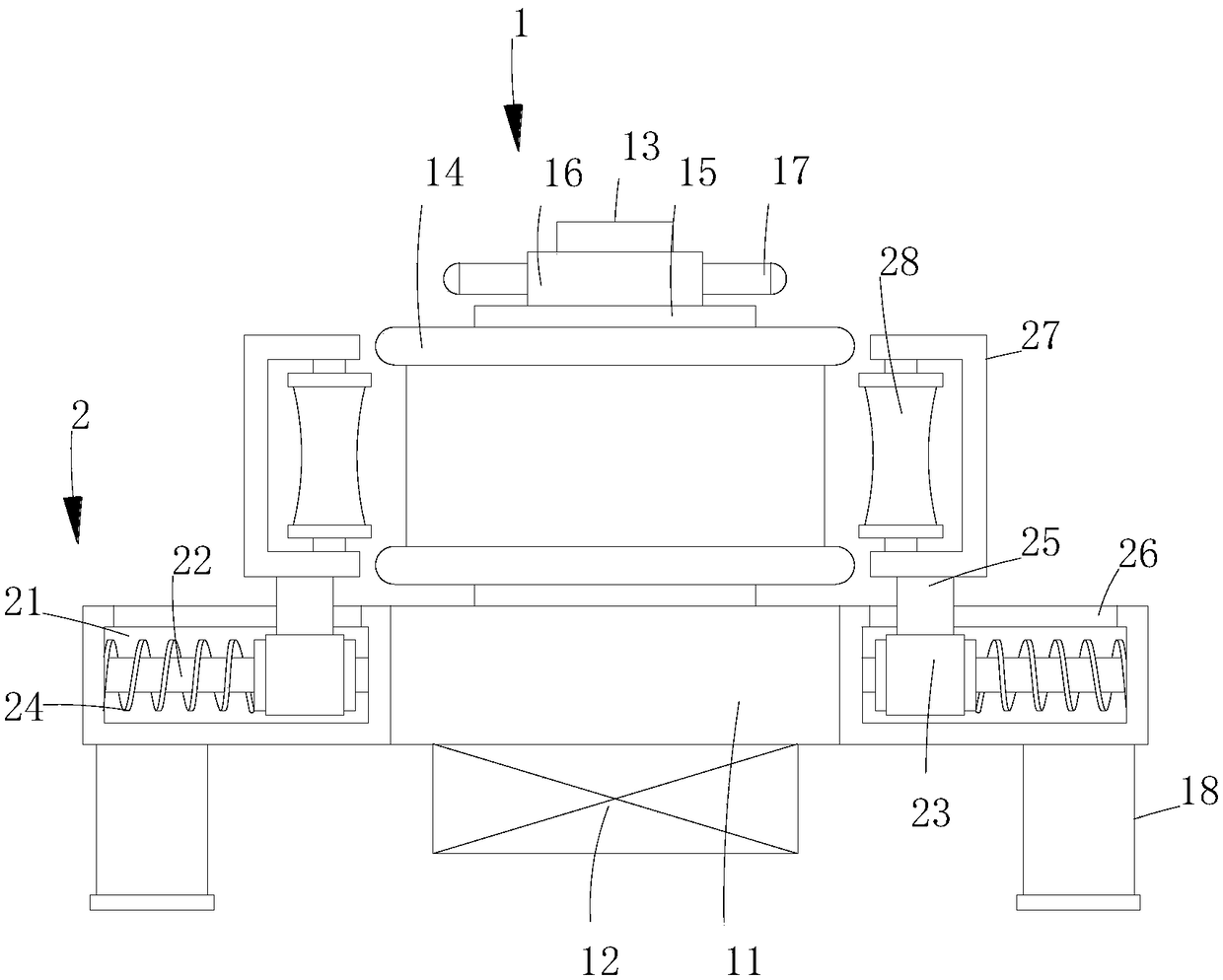

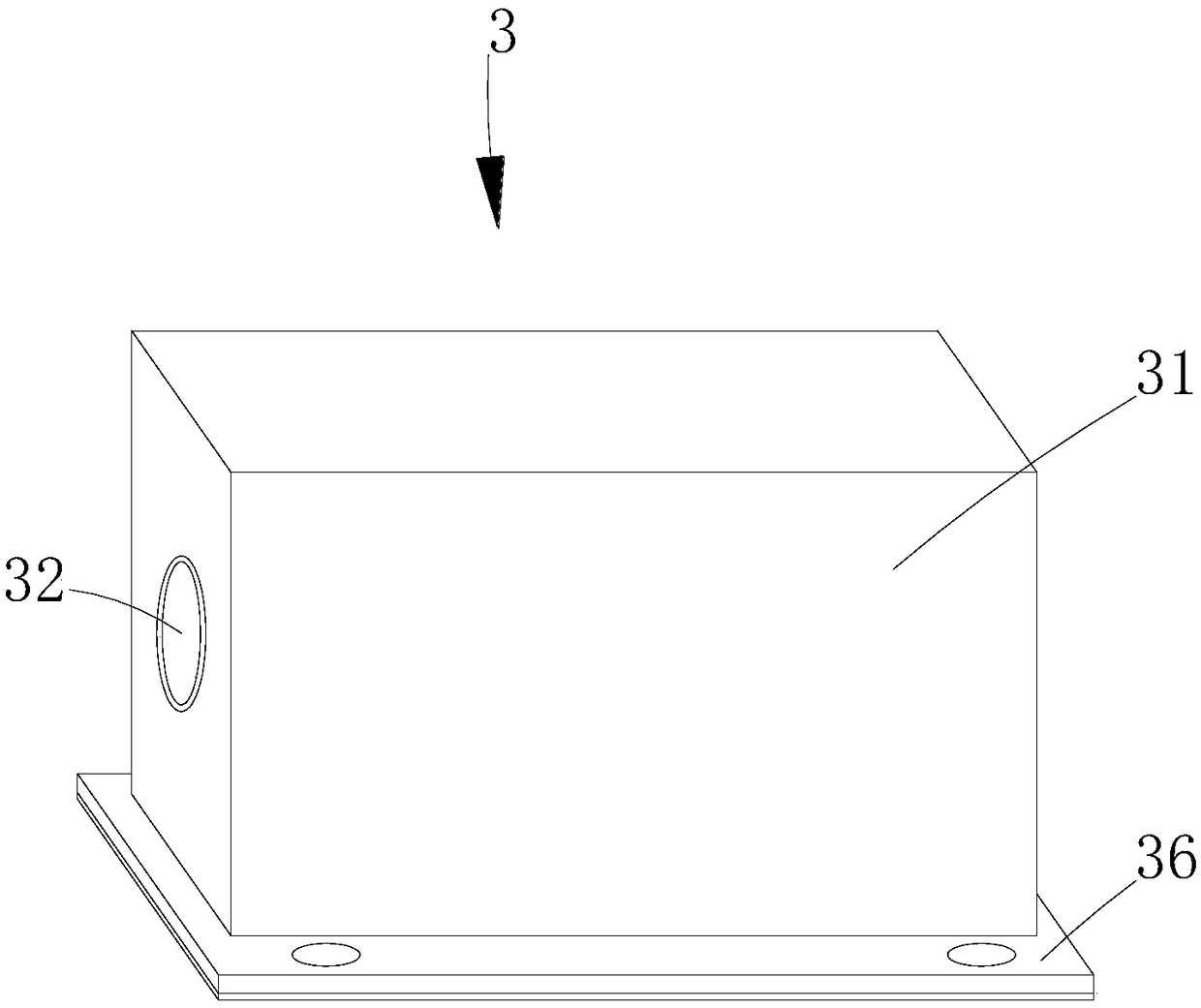

[0023] Such as Figure 1-4 As shown, the present invention provides a technical solution: an anti-off-coil winding mechanism for the processing and production of communication optical cables, including a winding device 1, an anti-coil device 2, and a cleaning device 3, and the anti-coil device 2 is located at the On both sides of the roll device 1, the cleaning device 3 is located on the back of the roll device 1, the roll device 1 includes a mounting plate 11, the bottom of the mounting plate 11 is fixedly connected with a support leg 18, and the bottom of the support leg 18 is fixedly connected with a non-slip pad , the middle position of the bottom of the mounting plate 11 is fixedly connected with a rotating motor 12, the output end of the rotating motor 12 is fixedly connected with a threaded rod 13, and the top of the threaded rod 13 runs through the top of the mounting plate 11 and extends to the top thereof, the threaded rod 13 The outer surface is sleeved with a reel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com