Grooving-chamfering machining process for automobile brake pad, and special grooving-chamfering combined machine

A processing technology and a technology for brake pads, applied in the field of slotting and chamfering combined machines, can solve the problems of low automation level, inconvenient first installation, easy to shake, etc. Position controllable and precise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with accompanying drawing:

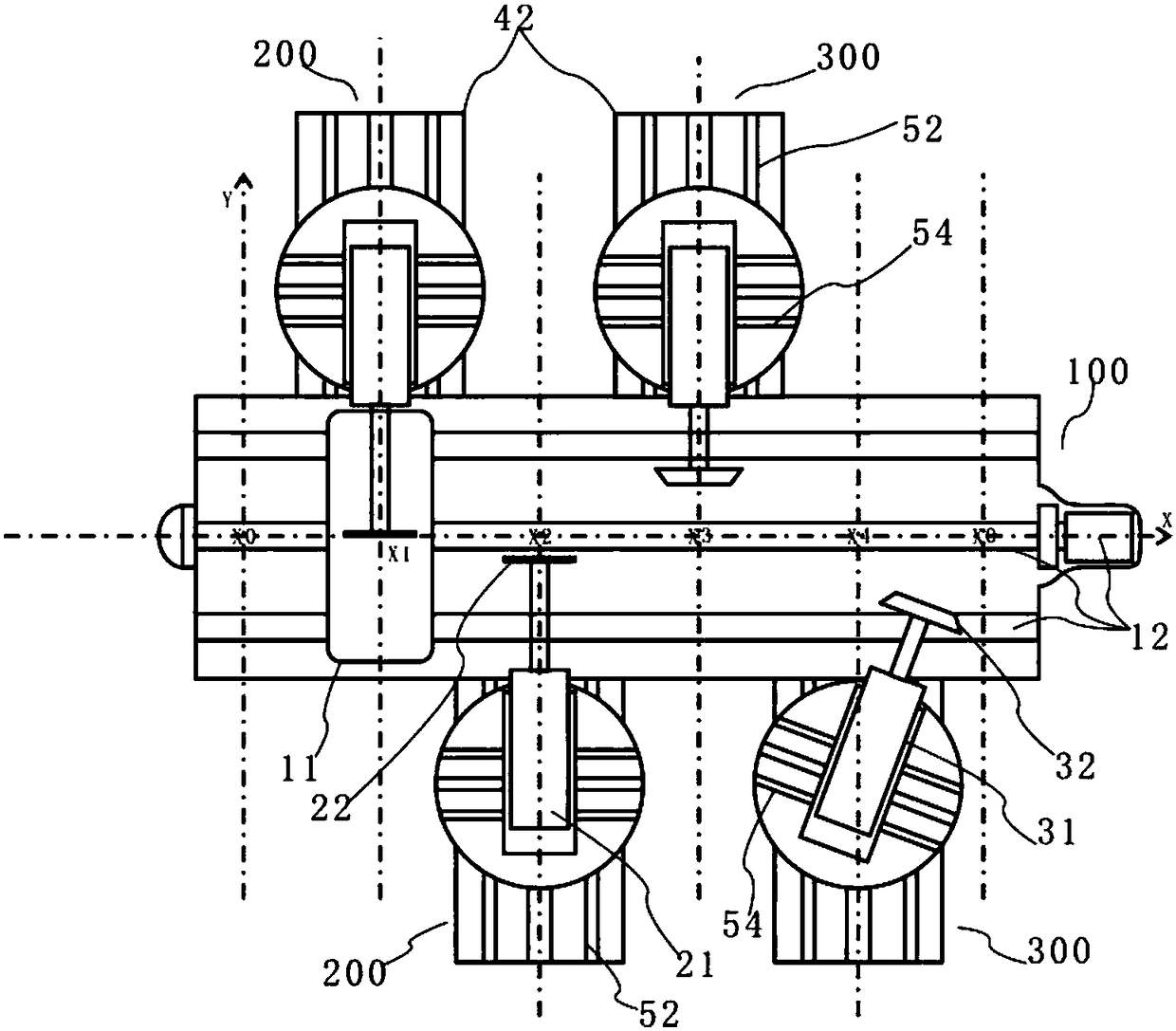

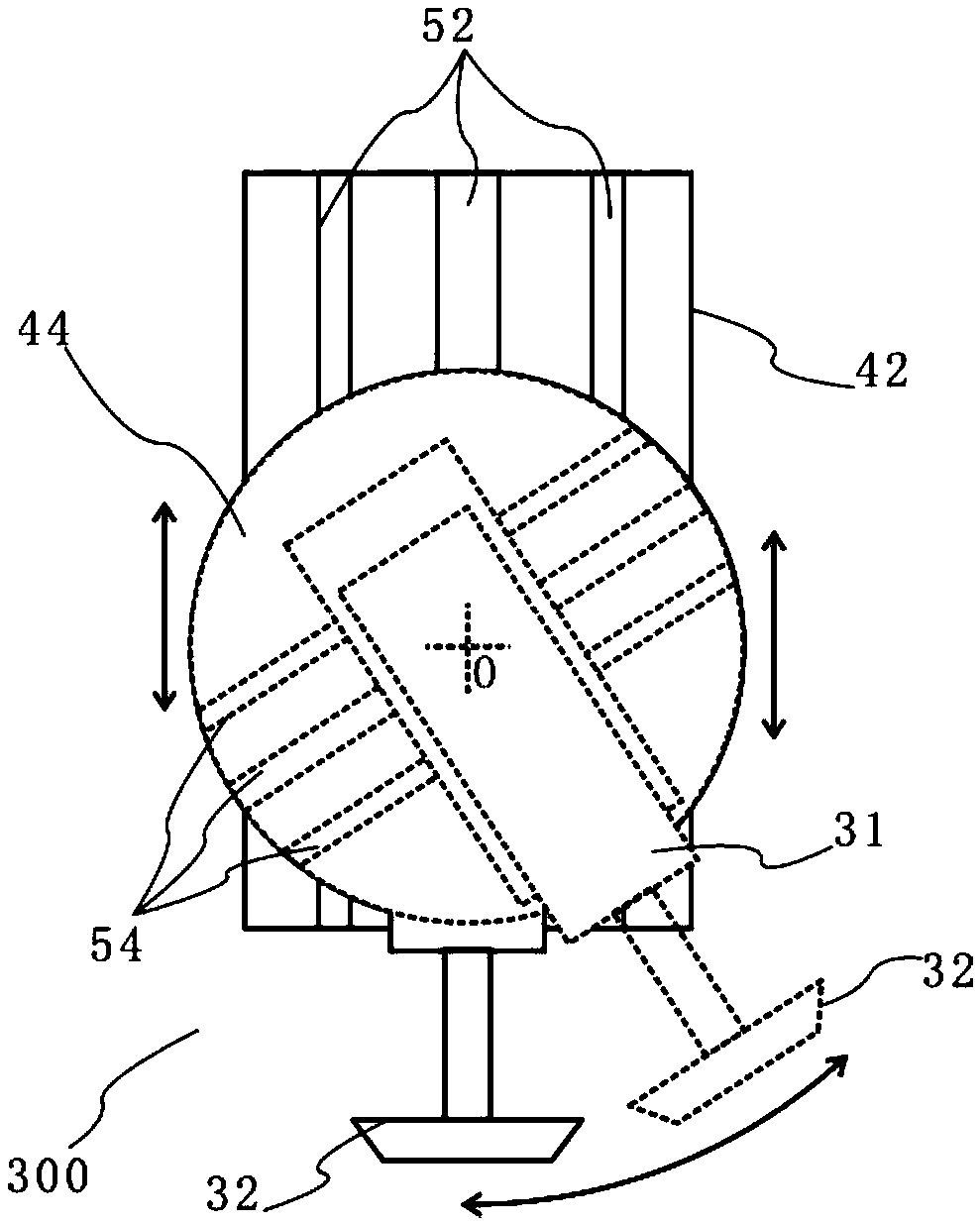

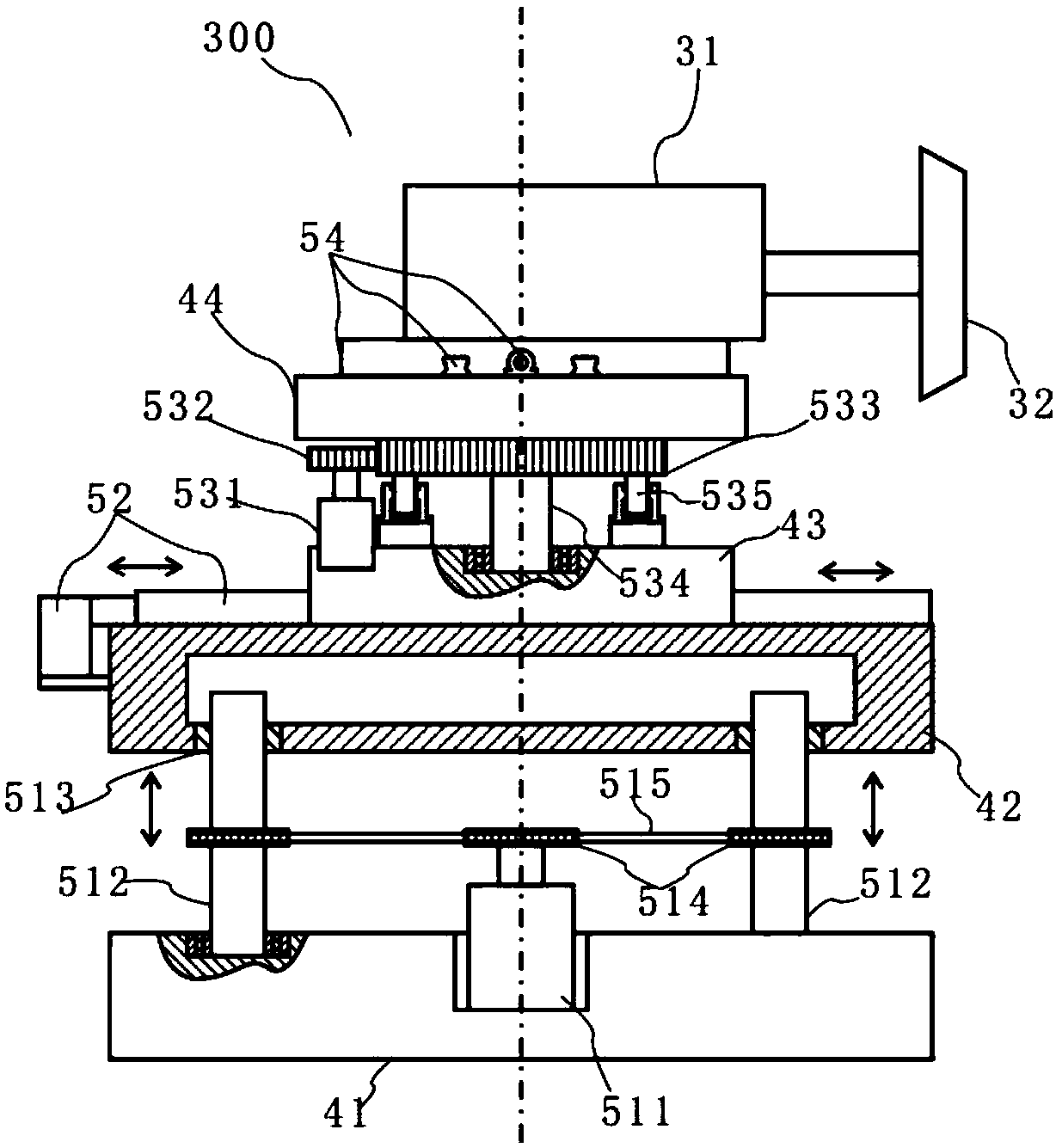

[0036] Such as Figure 1-5As shown, the present embodiment provides a slotting and chamfering combination machine for automobile brake pads, including a feeder mechanism 100 and functional units respectively arranged on both sides of the feeder mechanism 100 perpendicular to the feeder direction. The functional units described above include a slotting unit 200 and a chamfering unit 300. The slotting and chamfering combination machine is used for slotting and chamfering processing of automobile brake pads, wherein the slotting form includes but is not limited to Straight grooves parallel to the central axis of X and inclined grooves whose axis is inclined relative to the X central axis of the automobile brake pad. The chamfering of the hypotenuse with an included angle with respect to the X central axis of the automobile brake pad.

[0037] In this embodiment, the delivery...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com