Cooling and vibration reduction tool bar applied to machining for large-pitch screw rod

A technology with a large pitch and a shank, which is applied to tools for lathes, metal processing equipment, tool holders, etc., and can solve the problems of poor cooling effect in multi-blade cutting, poor cooling effect in multi-blade cutting, and large instantaneous vibration amplitude. , to achieve the effect of compact structure, reduced stiffness and efficient cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

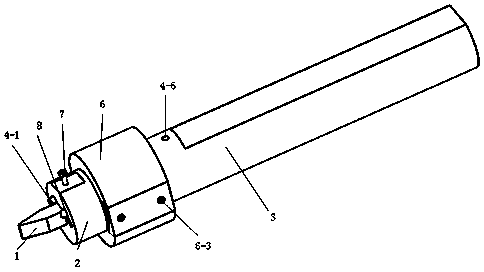

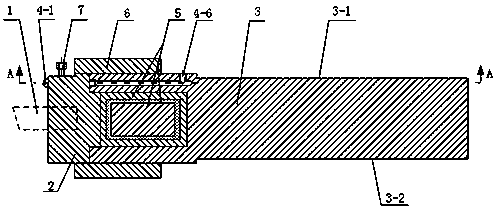

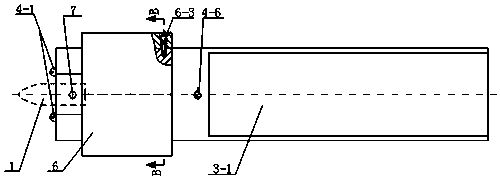

[0025] Embodiment 1, combining figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 and Figure 7This embodiment is described. In this embodiment, the present invention relates to a cooling and damping cutter bar applied to large-pitch screw processing, and a cooling and vibration-damping cutter rod applied to large-pitch screw processing. It is characterized in that, It comprises a turning tool 1, a tool holder head 2, a cutter holder body 3, a cooling unit 4, a damping unit 5 and a protective ring 6, the turning tool 1 is fixed on one end of the cutter holder head 2, and the other end of the cutter holder head 2 One end is provided with a protrusion, and one end of the cutter body 3 is provided with a groove. The damping unit 5 is located in the groove of the cutter body 3 and is a transition fit. The protrusion of the cutter head 2 and the cutter body 3 matched with the groove, used to fix the damping unit 5, the protective ring 6 is fastened on the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com