Preparation method of red-colored item beta-carotene preparation with high bioavailability

A carotene and utilization technology, applied in application, grain processing, food science, etc., can solve the problem of reducing the bioavailability and safety of β-carotene, failing to meet the requirements of natural red pigment, uncontrollable cis-trans isomerization, etc. problems, to achieve the effect of improving bioavailability and safety, broadening the scope of use, and benefiting food safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

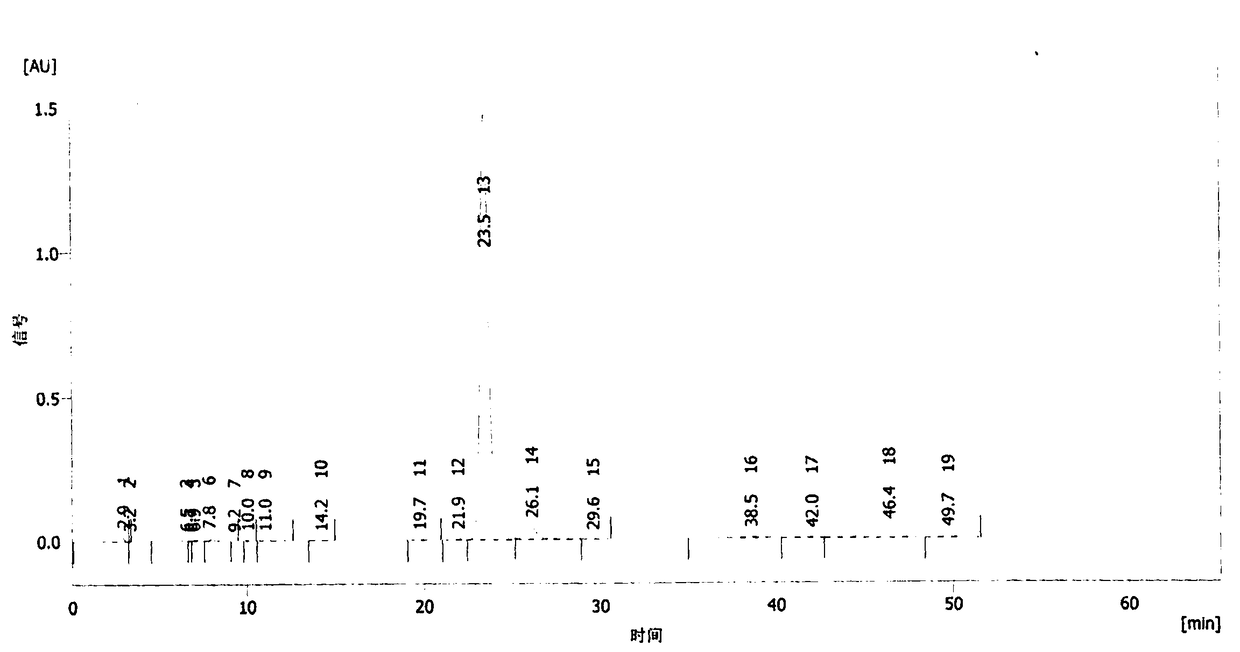

Image

Examples

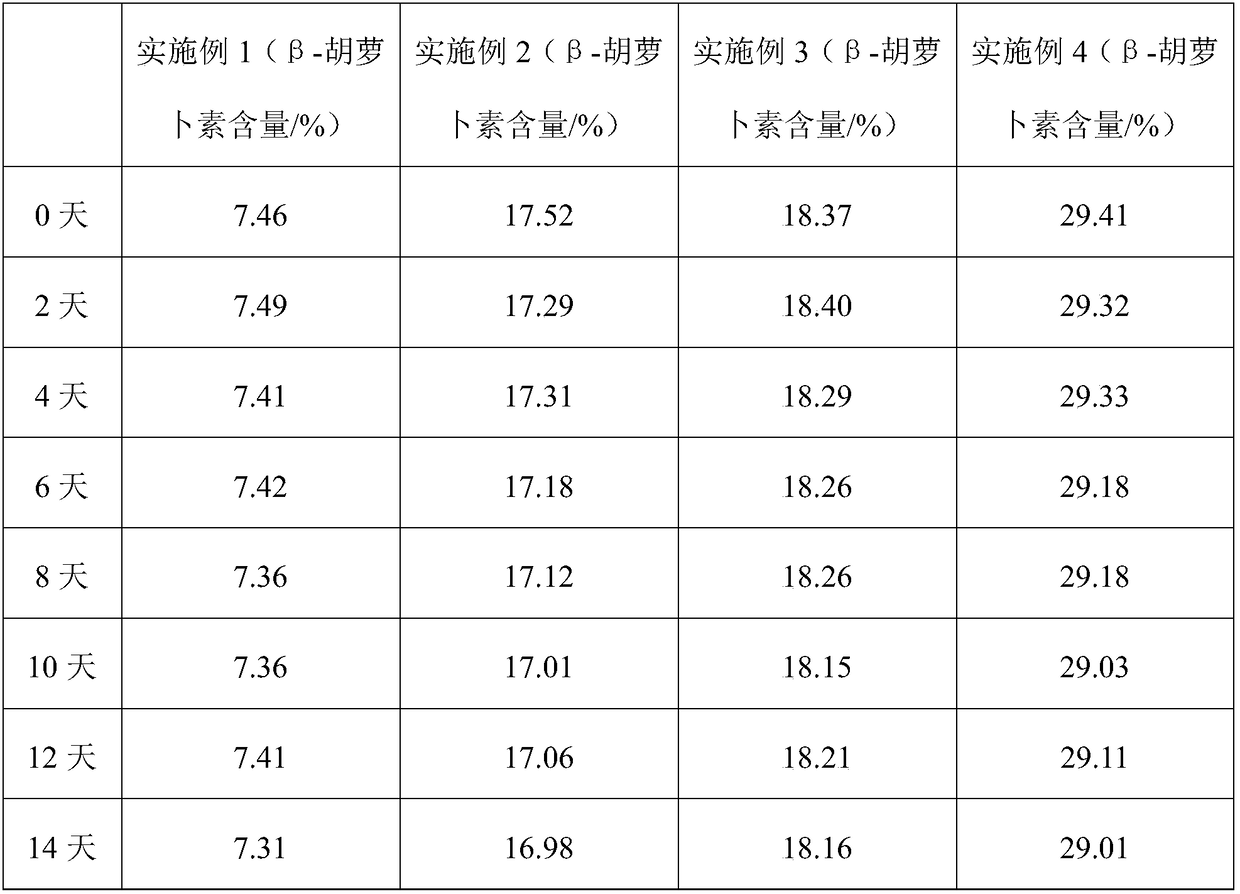

Embodiment 1

[0026] Take 50g of gum arabic, 2g of vitamin C, and 10g of maltodextrin in 1000ml of water, heat up to 50-60°C, stir until the materials are completely dissolved and form a water-soluble colloid; after the materials are completely dissolved, cool the materials to 30-32°C , put it aside. Take 5 g of β-carotene crystals (its all-trans content is 98.1%) and slowly add to the prepared water-soluble colloid, mix and homogenize online with a pipeline shearer, and control the shear rate within the range of 5000 to 6000 rpm. Obtain β-carotene suspension with uniform particle size. The β-carotene suspension is circularly ground by a nano-scale sand mill, and the grinding conditions are controlled at a pressure of 0.8-1.0MPa, a speed of 1500-2000rpm, and a temperature of 30-35°C until the particle size of the suspension reaches 100nm ~300nm to form a nanosuspension. The obtained nano-suspension was spray-dried and granulated into β-carotene microcapsule powder. The microcapsule powder...

Embodiment 2

[0028] Take 50g of modified starch, 7g of synthetic tocopherol, and 35g of syrup in 1000ml of water, heat up to 65-75°C, stir until the material is completely dissolved and form a water-soluble colloid; after the material is completely dissolved, cool the material to 35-40°C , put it aside. Take 17.5 g of β-carotene crystals (its all-trans content is 98.3%) and slowly add to the prepared water-soluble colloid, mix and homogenize online with a pipeline shearer, and control the shear rate within the range of 10,000 to 12,000 rpm , to obtain β-carotene suspension with uniform particle size. The β-carotene suspension is circularly ground by a nano-scale sand mill, and the grinding conditions are controlled at a pressure of 1.0-1.2MPa, a speed of 2000-2500rpm, and a temperature of 35-40°C until the particle size of the suspension reaches 100nm ~300nm to form a nanosuspension. The obtained nano-suspension was spray-dried and granulated into β-carotene microcapsule powder. The micr...

Embodiment 3

[0030]Take 50g of hydrolyzed soybean protein, 7g of mixed tocopherols, and 50g of maltooligosaccharide in 1000ml of water, heat up to 75-80°C, and stir until the materials are completely dissolved to form a water-soluble colloid; after the materials are completely dissolved, cool the materials to 40-80°C. 45°C, put it aside. Take 25.0 g of β-carotene crystals (its all-trans content is 98.6%) and slowly add to the prepared water-soluble colloid, mix and homogenize online with a pipeline shearer, and control the shear rate within the range of 20,000 to 25,000 rpm , to obtain β-carotene suspension with uniform particle size. The β-carotene suspension is circularly ground by a nano-scale sand mill, and the grinding conditions are controlled at a pressure of 1.2-1.5MPa, a speed of 2500-3000rpm, and a temperature of 40-45°C until the particle size of the suspension reaches 100nm ~300nm to form a nanosuspension. The obtained nano-suspension was spray-dried and granulated into β-car...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com