Anti-aging starch ball can and preparation method thereof

An anti-aging and starch technology, applied in the field of food processing, can solve problems such as singleness, and achieve the effects of inhibiting aging, not easy to chew, and having great economic value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

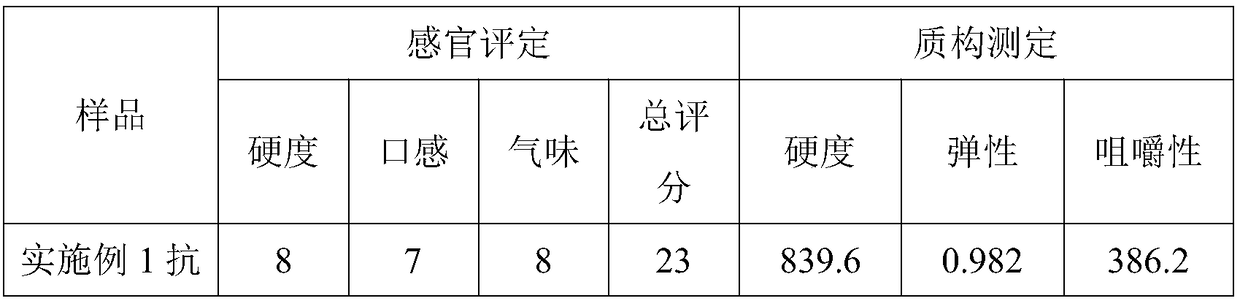

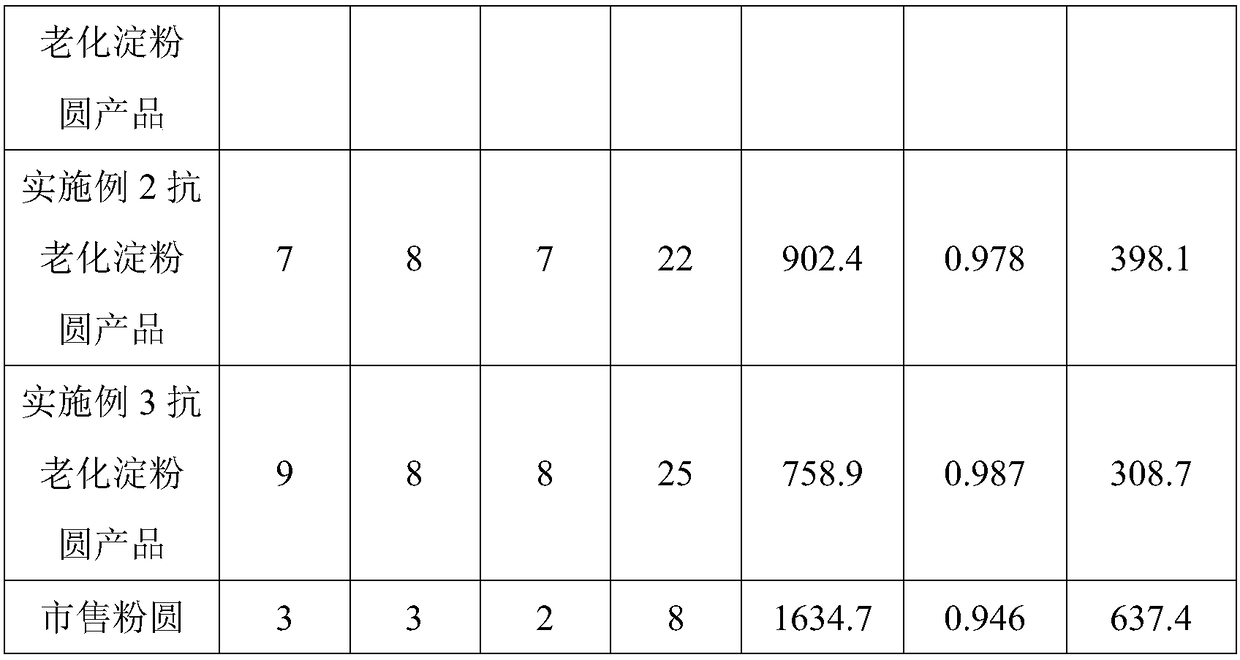

Examples

preparation example Construction

[0025] The preparation method of the anti-aging starch round can includes the following steps:

[0026] Step A. Preparation of raw materials: Weigh each raw material according to the amount of the formula, mix the pure grass powder, anhydrous dextrose, water, and tapioca starch evenly to form a nearly spherical mass;

[0027] Step B. Granulation: The pellets are processed into powder circles with a diameter of 6mm through the three processes of extrusion, rolling and pelletizing using pelletizing equipment;

[0028] Step C, hot blanching treatment: place the prepared dough balls in hot water containing 0.5% calcium chloride (maintained at 90°C) for 5 minutes, remove and drain;

[0029] Step D, canning sterilization: add 30% sugar water (heated to 80°C in advance) to the drained powder circle for hot filling, and sterilize after sealing the can, the sterilization temperature is 121°C, and the sterilization time is 30 minutes.

example 1

[0032] A preparation method of anti-aging starch round cans includes the following steps:

[0033] (1) Preparation of raw materials: first add 8 kg of pure grass powder to the preparation tank, pour 40 kg of water, and stir evenly; then add 5 kg of anhydrous dextrose and stir evenly; then add 55 kg of tapioca starch , Mix and stir to form approximately spherical agglomerates;

[0034] (2) Granulation: The pellets are processed into powder circles with a diameter of 6mm through the three processes of extrusion, rolling and pelletizing using pelletizing equipment;

[0035] (3) Hot blanching treatment: place the prepared dough balls in hot water containing 0.5% calcium chloride (maintained at 90°C) for 5 minutes, remove and drain;

[0036] (4) Canned sterilization: Add 30% sugar water (heated to 80°C in advance) to the drained powder circle for hot filling, and seal the can for sterilization.

example 2

[0038] A preparation method of anti-aging starch round cans includes the following steps:

[0039] (1) Preparation of raw materials: add 8 kg of pure grass powder, 5 kg of anhydrous dextrose, and 55 kg of tapioca starch into the mixer and mix thoroughly, then pour into the preparation tank, add 40 kg of water, and mix well , Made into approximately spherical agglomerates;

[0040] (2) Granulation: The pellets are processed into powder circles with a diameter of 6mm through the three processes of extrusion, rolling and pelletizing using pelletizing equipment;

[0041] (3) Hot blanching treatment: place the prepared dough balls in hot water containing 0.5% calcium chloride (maintained at 90°C) for 5 minutes, remove and drain;

[0042] (4) Canned sterilization: Add 30% sugar water (heated to 80°C in advance) to the drained powder circle for hot filling, and seal the can for sterilization.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com