Repairing method and repairing device

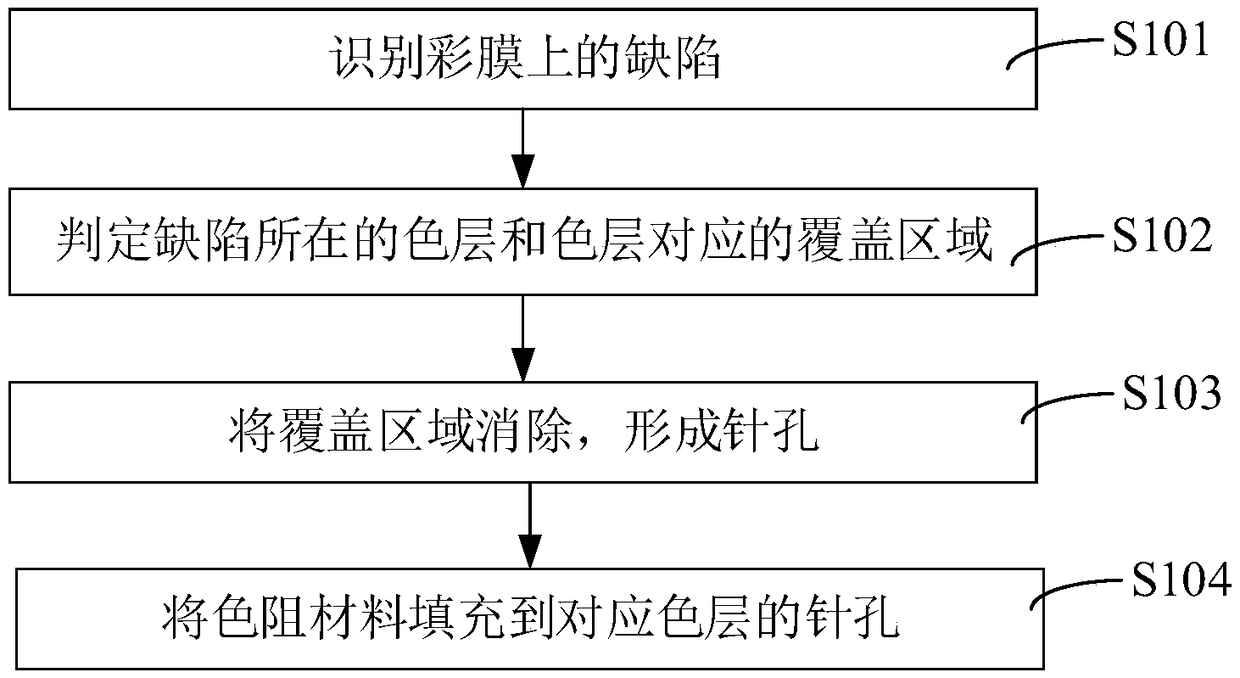

A defect and color layer technology, applied in the field of repair methods and devices, can solve the problems of large influence of human factors, many operators, low repair speed and repair quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

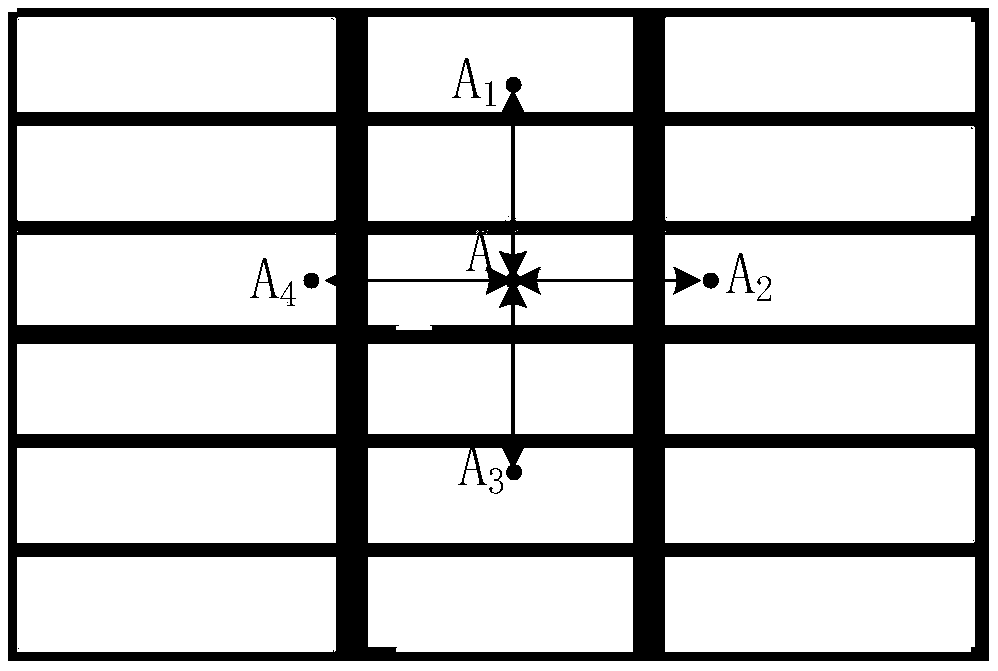

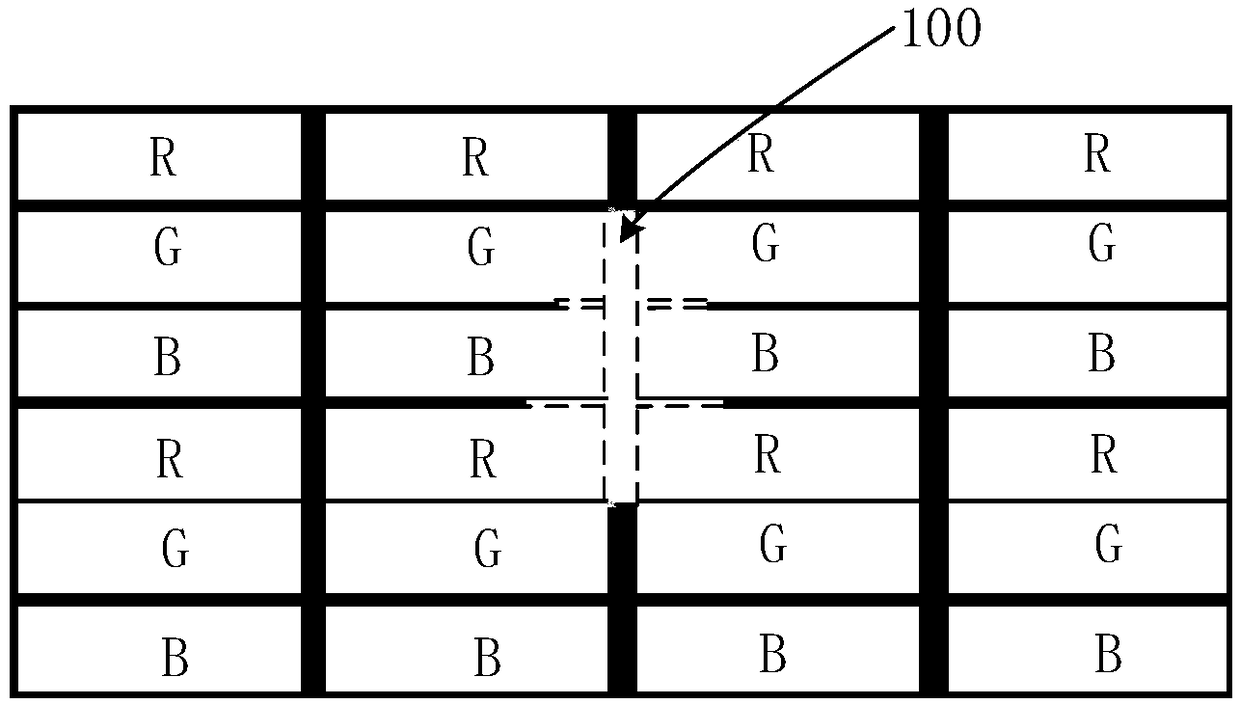

[0075] Example 1, see image 3 ( image 3 The dotted line area is the defect) and Figure 4 ( Figure 4 The middle shadow part is the black matrix, and the transparent part is the color layer).

[0076] Step S1011: Identify defects on the color filter.

[0077] Step S1012: It is determined that the defect is on the black matrix, and the coverage area corresponding to the defect on the black matrix is identified as area 100 through border rectangleization.

[0078] Step S1013: Laser etching the region 100 by laser to form pinholes.

[0079] Step S1014: Fill the pinholes with black photoresist material to complete defect repair (see Figure 4 ).

Embodiment 2

[0080] Example 2, see Figure 5 ( Figure 5 The shaded area of the irregular pattern in includes black matrix and black defect, where the black defect is caused by overfilling of black photoresist material) and Image 6 ( Image 6 The middle shadow part is the black matrix, and the transparent part is the color layer).

[0081] Step S1011: Identify defects on the color filter.

[0082] Step S1012: Determine that the defects are located on the R color layer, G color layer, and B color layer, identify the boundaries of the sub-defects on each color layer, and rectangularize the boundaries to obtain a defect area 100, wherein the rectangular coverage area of the R color layer is area 101 , the rectangular coverage area of the G color layer is the area 102 and the rectangular coverage area of the B color layer is the area 103 .

[0083] Step S1013 : laser etching the region 101 , the region 102 and the region 103 to form pinholes.

[0084] Step S1014: Fill the red col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com