Vehicle dynamic balance tensioning method and tightening device on chassis dynamometer in anechoic room

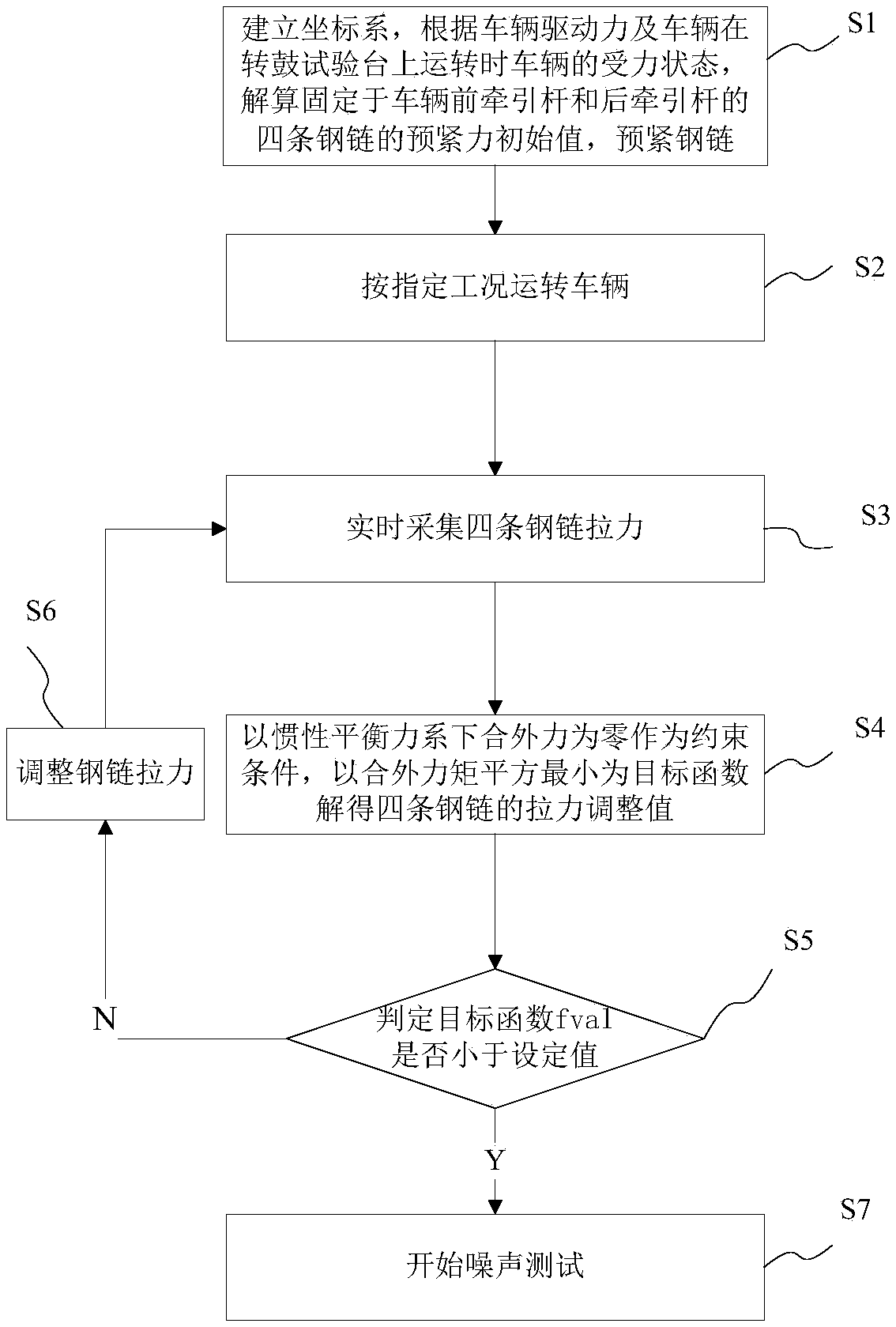

A dynamic balance, drum test technology, used in measurement devices, vehicle testing, machine/structural component testing, etc., to solve problems such as vehicle swing, tire noise, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0397] Taking four-wheel drive acceleration as an example, enter the following parameters in the solution formula:

[0398]

[0399] Substituting the static balance expression, the initial value of the pre-tightening force of the steel chain 3 can be obtained, and the initial value of the pre-tightening force is:

[0400] f 10 =98.8N; F 20 =854.1N; F 30 =3.7757e+03N; F 40 =2.4608e+03N.

[0401] During the vehicle 10 test, due to the influence of factors such as the elasticity of the steel chain 3, tire friction characteristics, and improper placement of the vehicle 10, its acceleration presents an oscillation characteristic, and the tension fluctuation amplitude is a time-varying function, which can be approximately expressed as:

[0402] a=a 0 +△a sin(ωt);

[0403] In the formula, a 0 is the acceleration of the specified working condition; △a is the tension fluctuation amplitude, usually a 0 5%, ω is the acceleration fluctuation angular frequency, ω=2πf, f=2~5Hz. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com