Combined-type loose-proof nut

A locknut and composite technology, applied in the direction of nuts, screws, bolts, etc., can solve the problems of low work efficiency, high production cost, low yield, etc., to improve the connection tightness, improve the smoothness of the connection, and smooth the thread delayed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

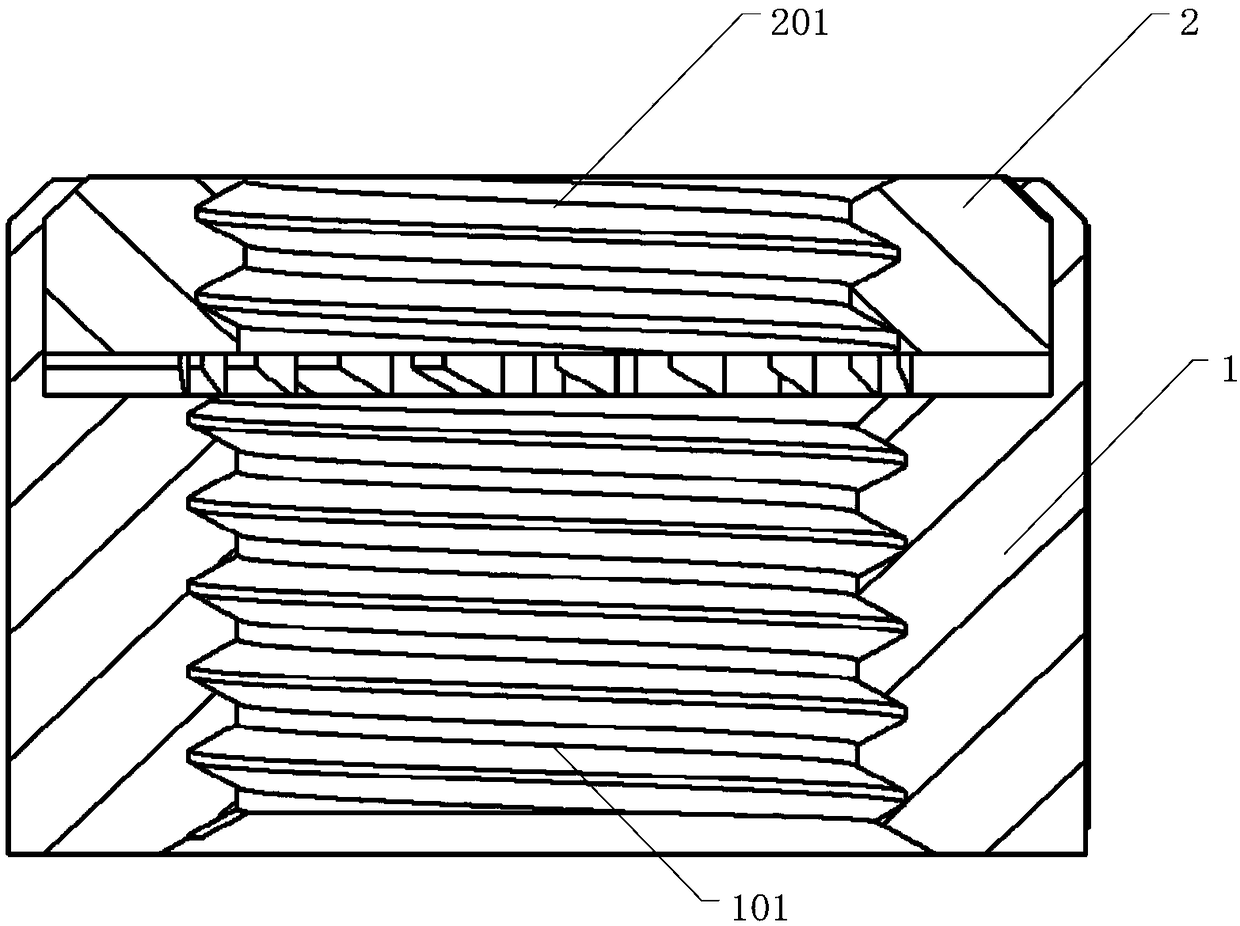

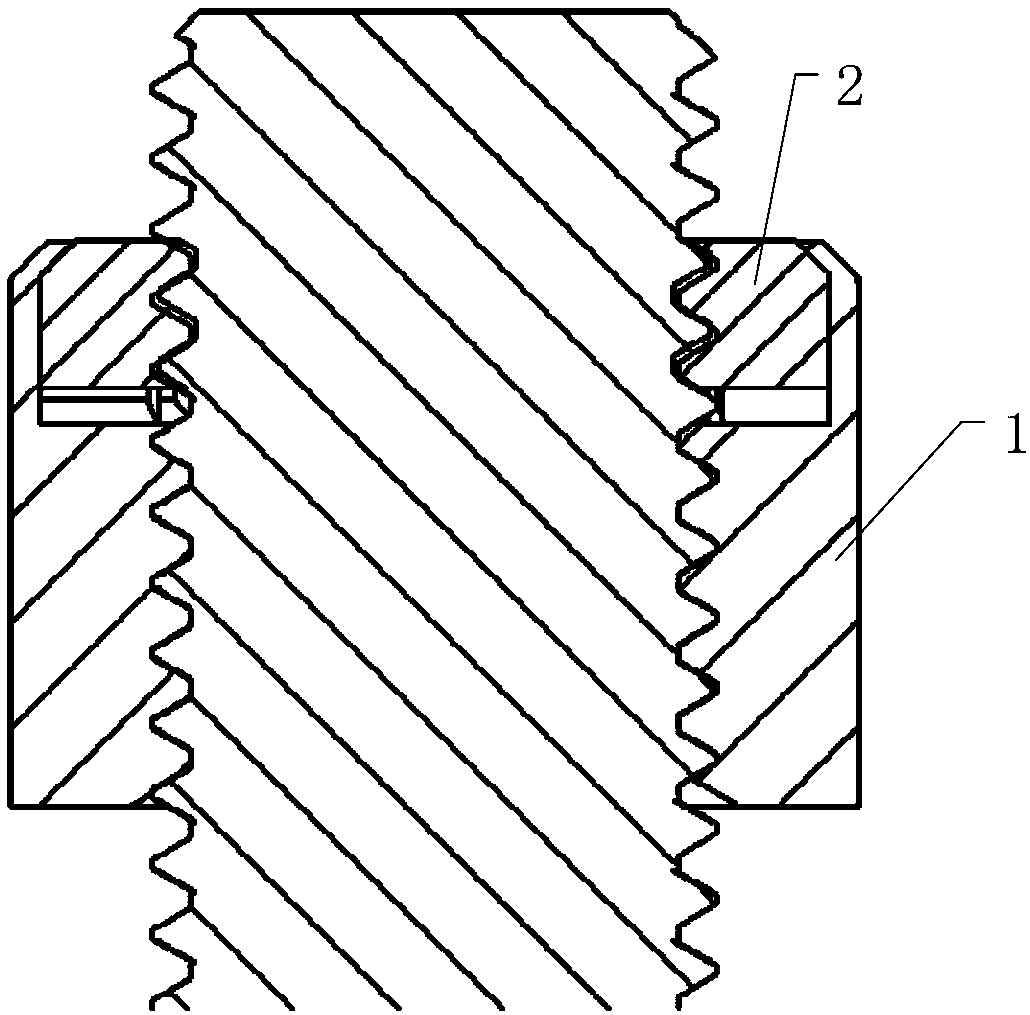

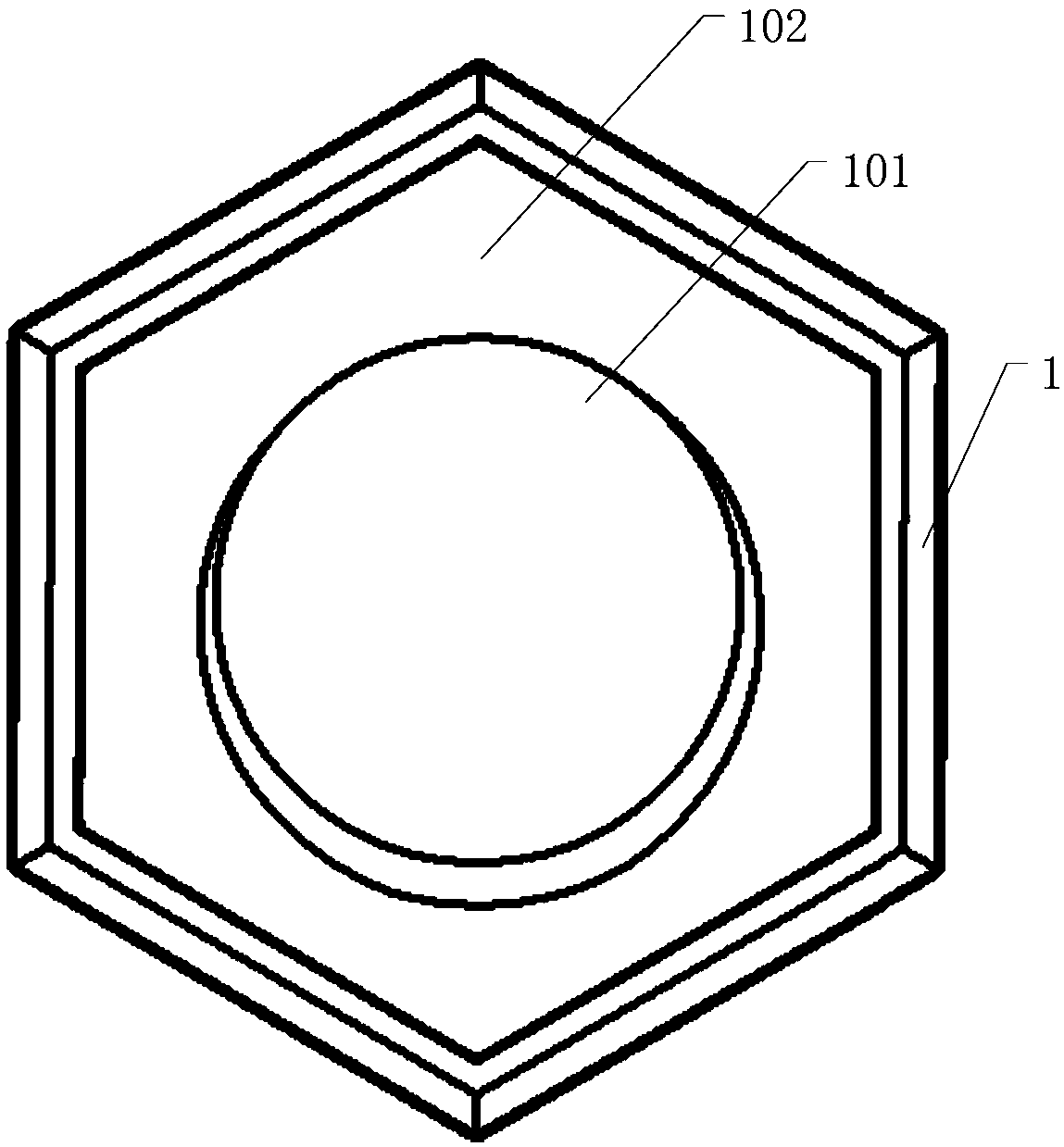

[0036] Such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 7 As shown, this embodiment discloses a composite anti-loosening nut, including a nut body 1 and an elastic anti-loosening member 2 arranged on the nut body. Specifically, one end face of the nut body is provided with a countersunk hole 102 in the axial direction, and the elastic anti-loosening part is fixedly arranged in the countersunk hole and the elastic anti-loosening part is provided with a threaded hole 201, and the threaded hole It is coaxial with the central threaded hole 101 of the nut body; the lower end surface of the elastic anti-loosening part is evenly provided with an elastic part 202 according to the circumference, and the elastic part and the elastic anti-loosening part are integrally formed and the lower end of the elastic part contacts the bottom of the counterbore.

[0037] The role of the elastic anti-loosening part is to use plastic deformation to hold the bolt or screw tightly, a...

Embodiment 2

[0046] This embodiment discloses a composite anti-loosening nut, which includes a nut body and an elastic anti-loosening part arranged on the nut body. Specifically, one end face of the nut body is axially provided with a counterbore, the elastic anti-loosening part is fixedly arranged in the counterbore, and the elastic anti-loosening part is provided with a threaded hole, the threaded hole and the nut The central threaded hole of the body is coaxial; the lower end surface of the elastic anti-loosening part is uniformly provided with elastic parts according to the circumference, and the elastic part and the elastic anti-loosening part are integrally formed and the lower end of the elastic part contacts the bottom of the countersunk hole; the countersunk hole A limit structure is provided at the orifice, and the limit structure is in contact with the upper end surface of the elastic anti-loosening part.

[0047] The difference between this embodiment and embodiment 1 is:

[0...

Embodiment 3

[0051] This embodiment discloses a composite anti-loosening nut, which includes a nut body and an elastic anti-loosening part arranged on the nut body. Specifically, one end face of the nut body is axially provided with a counterbore, the elastic anti-loosening part is fixedly arranged in the counterbore, and the elastic anti-loosening part is provided with a threaded hole, the threaded hole and the nut The central threaded hole of the body is coaxial; the lower end surface of the elastic anti-loosening part is uniformly provided with elastic parts according to the circumference, and the elastic part and the elastic anti-loosening part are integrally formed and the lower end of the elastic part contacts the bottom of the countersunk hole; the countersunk hole A limit structure is provided at the orifice, and the limit structure is in contact with the upper end surface of the elastic anti-loosening part.

[0052] The difference between this embodiment and embodiment 2 is:

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com