Micro-perforated resonant cavity muffling structure and noise-reduction muffler for auxiliary power units (APU)

A resonant cavity and micro-perforation technology, applied in mufflers, machines/engines, engine components, etc., can solve the problems of reducing exhaust speed, equipment damage, complex structure, etc., to reduce noise intensity, improve production efficiency, and reduce processing. The effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

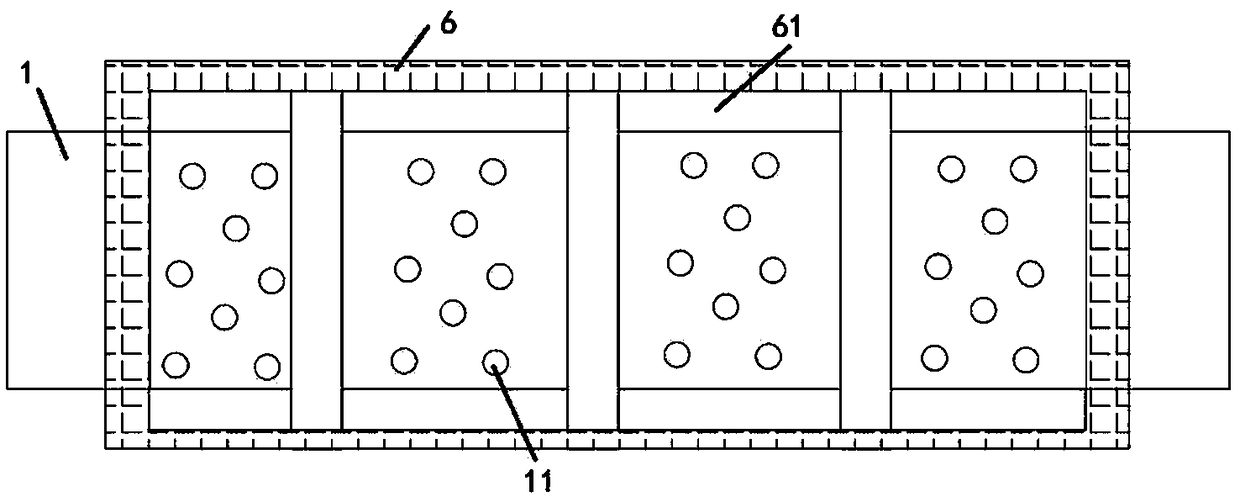

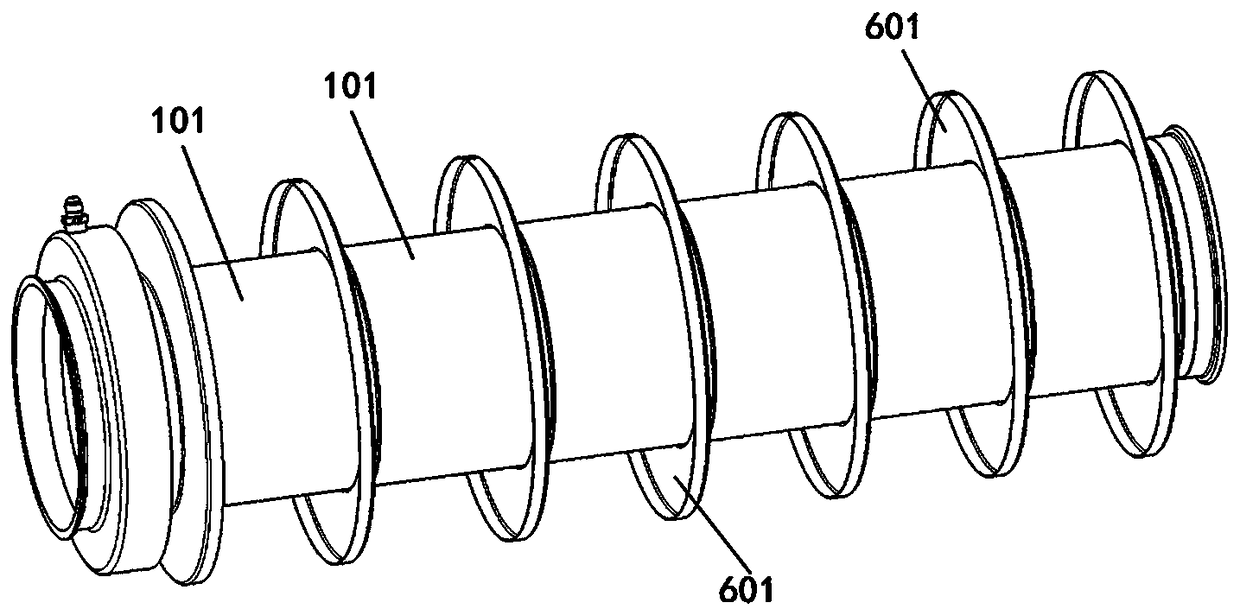

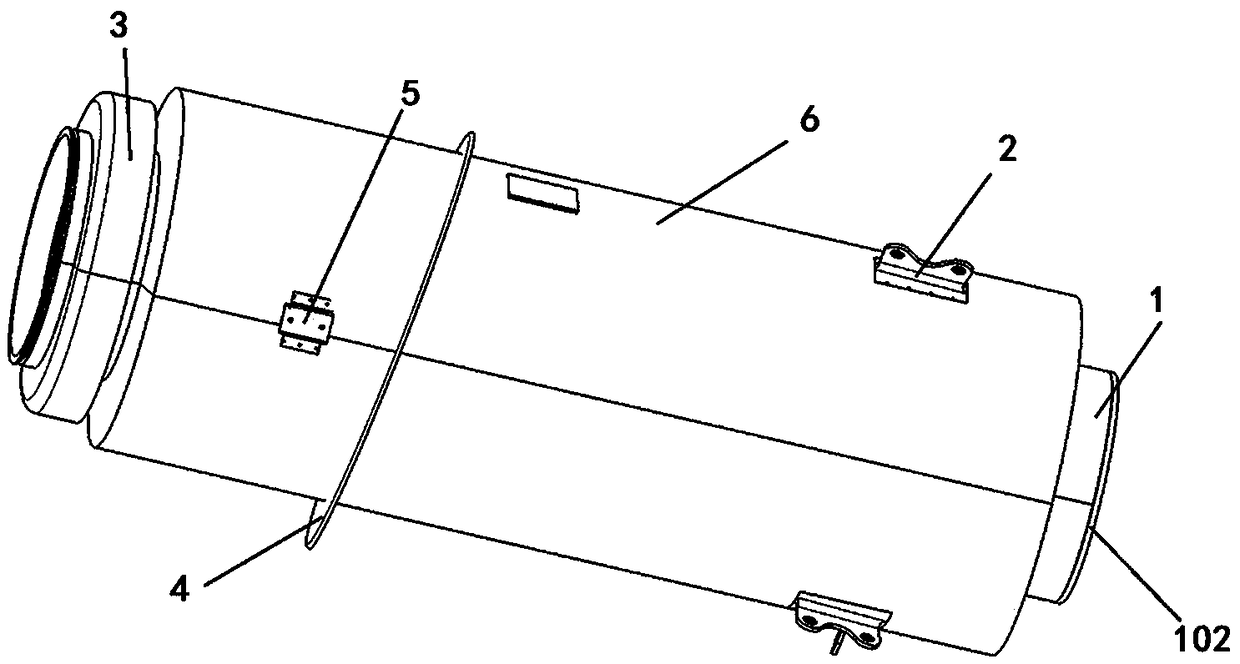

[0021] Please refer to figure 1 , a micro-perforated resonant cavity noise reduction structure provided by the present invention includes an inner cylinder assembly 1 and an outer cylinder 6. The outer cylinder 6 is a hollow cylinder with a cavity 61 inside, and openings at both ends for opening into it. Inner port; the inner cylinder assembly 1 passes through the outer cylinder 6 through the opening, and is fixedly connected with the inner cylinder assembly 1 through a number of muffler structures; a number of muffler through holes 11 are opened on the inner cylinder assembly 1, and the exhaust gas is discharged from the inner cylinder One end of the cylinder assembly 1 enters the inner cylinder assembly 1, and the sound wave enters the muffler cavity formed by the inner cylinder assembly 1, the outer cylinder 6 and the muffler structure through the mu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com