Construction method for fabricated lined tunnel resistant to active fault movement

An active fault and assembled technology, applied in the direction of tunnel, wellbore lining, tunnel lining, etc., can solve the problems that it is difficult to take thickening and reinforcement measures, and it is difficult to resist the dislocation and vibration damage of active faults, so as to achieve convenient secondary Reinforce maintenance, enhance the overall anti-mistake performance, and avoid impact effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

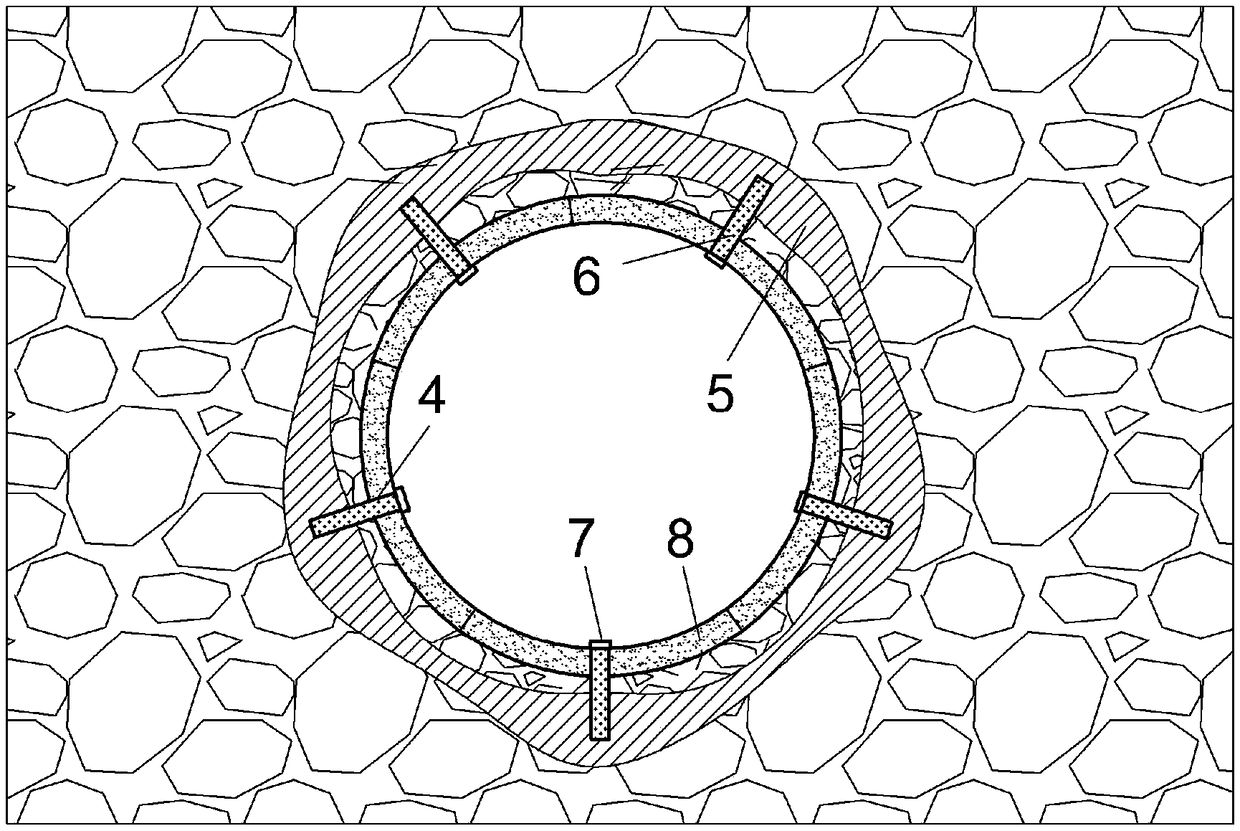

[0027] figure 1 , figure 2 It is shown that a specific embodiment of the present invention is a method for constructing a prefabricated lining tunnel against active fault dislocation, the steps of which are:

[0028] A. to dig a tunnel

[0029] After excavation and entry into the active fault crossing area, blasting and excavation are carried out in the active fault crossing area to complete the installation of segment 8 and synchronous grouting of the prefabricated lining tunnel;

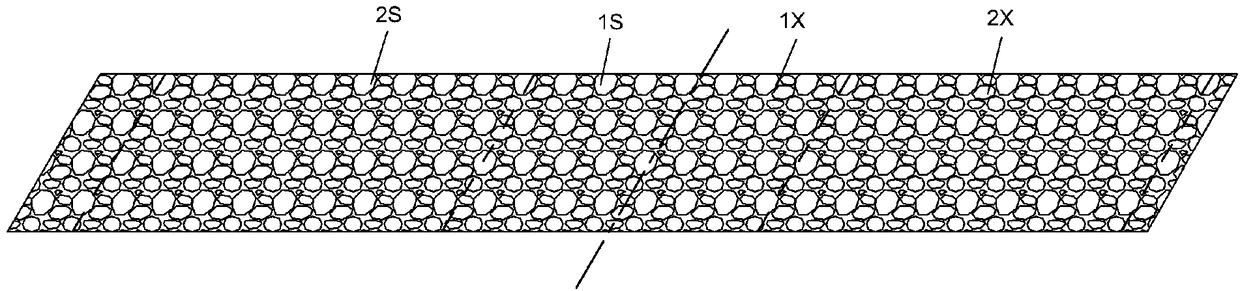

[0030] The active fault crossing area is composed of the hanging wall 1S of the active fault zone, the footwall 1X of the broken zone, the hanging wall transition section 2S adjacent to the hanging wall 1S of the broken zone, and the footwall transition section 2X adjacent to the footwall 1X of the broken zone; Among them, the length range of the upper wall transition section 2S and the lower wall transition section 2X is obtained from the following table:

[0031]

Upper wall tran...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com