Improved bamboo thread board and poplar skin composite floor

A composite floor and veneer technology, applied in the field of flooring, can solve the problems of delayed generation efficiency, not very beautiful appearance, waste of manpower, etc., and achieve the effect of reasonable overall structure setting, good moisture-proof and mute performance, and improved friction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

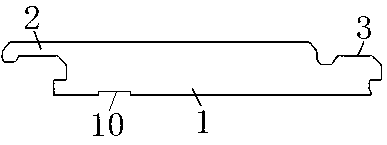

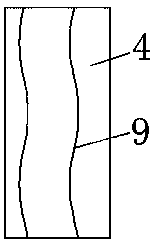

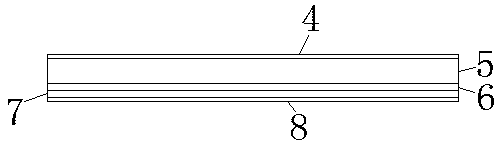

[0013] Such as figure 1 , figure 2 and image 3 As shown, an improved heavy bamboo poplar veneer composite floor according to the present invention includes a floor body 1, and a tongue and groove 2 and a tongue 3 are respectively provided on both sides of the floor body 1 in the width direction, and the floor body 1 sequentially includes wear-resistant anti-slip layer 4, heavy bamboo layer 5, poplar cortex I6, poplar cortex II7 and high-density flax fiber layer 8, the wear-resistant anti-slip layer 4, heavy bamboo layer 5, poplar cortex I6, poplar The thickness ratio of the veneer layer II 7 and the high-density flax fiber layer 8 is 1:9:2:2:1, and the wear-resistant and anti-slip layer 4 is provided with anti-slip lines 9; the wear-resistant and anti-slip layer 4 is made of di Aluminum wear-resistant layer; a ventilation slot 10 is provided at the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com