Prefabricated assembly device for rapidly increasing culvert bearing capacity and method for strengthening culvert

A prefabricated assembly and bearing capacity technology, applied in the field of culvert reinforcement, can solve the problems of difficult construction work, narrow culvert space, water accumulation in sewer pipes, etc., and achieve the effect of accelerating reinforcement efficiency, avoiding construction environment, and improving bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

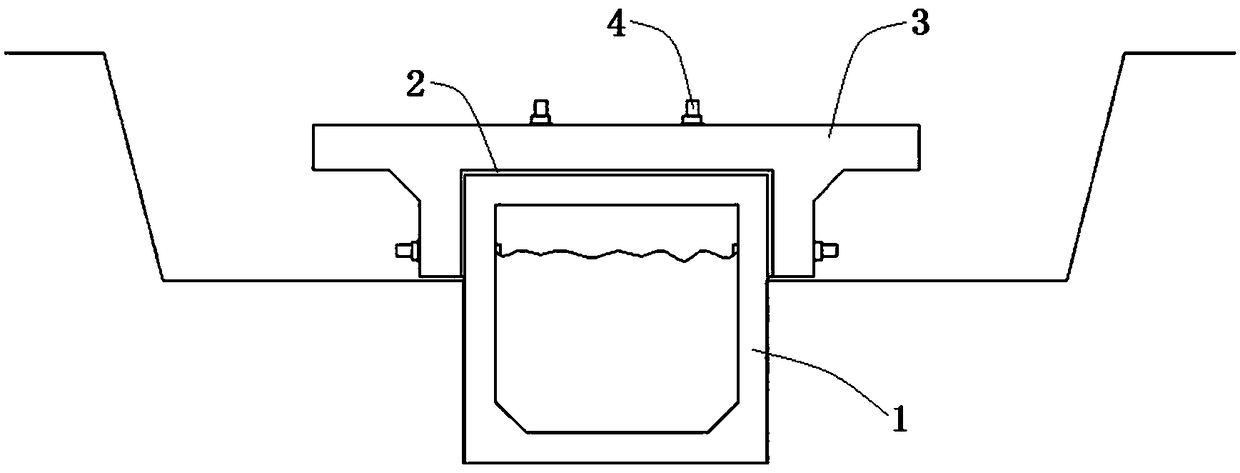

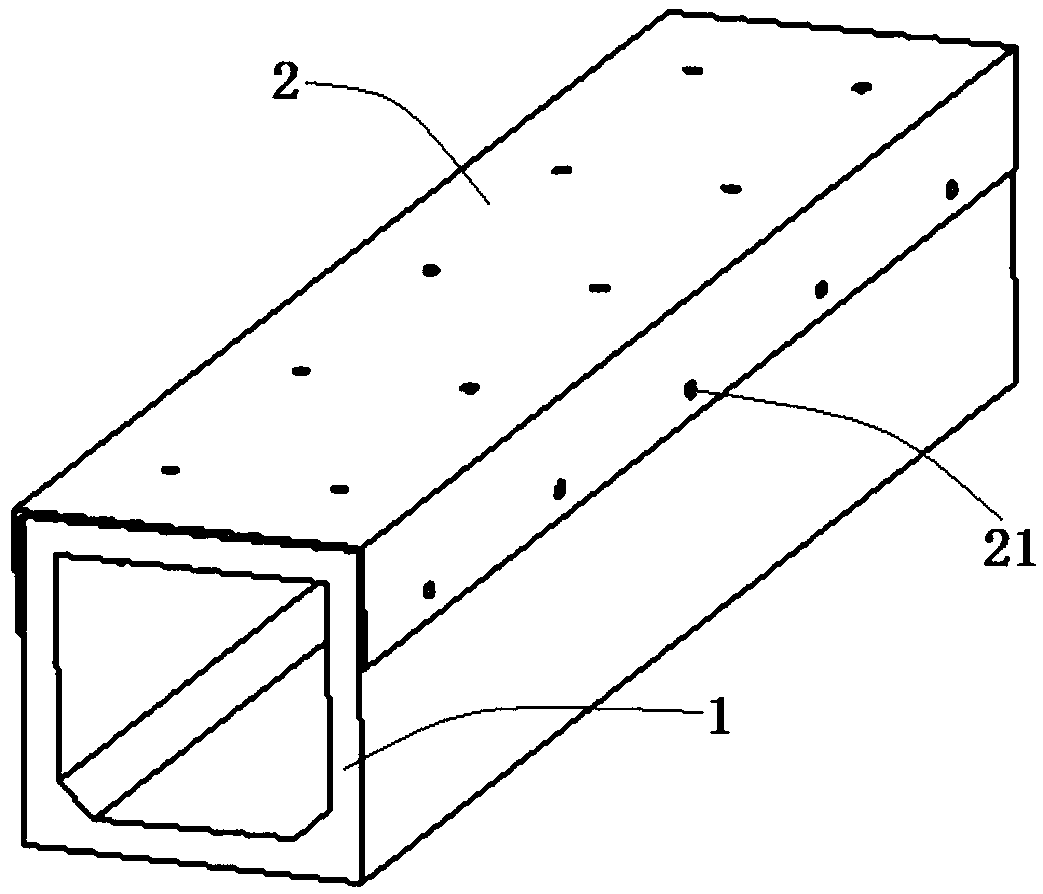

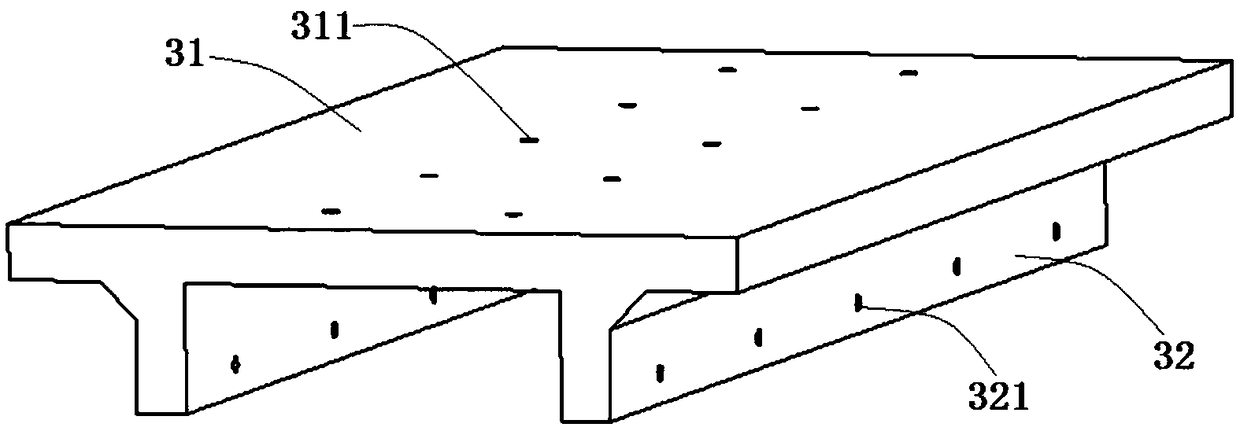

[0032] This specific embodiment discloses a prefabricated assembly device for quickly improving the bearing capacity of a culvert, such as image 3 As shown, it includes a top plate 31 and flanges 32 on both sides of the top plate. The top plate 31 is used to be installed on the top of the culvert 1, and the flange 32 is used to be installed on both sides of the culvert 1. The dimensions of the top plate 31 and the flanges 32 are based on the size of the culvert 1. The size is prefabricated, the thickness of the top plate 31 can be designed according to the stiffness according to the increase of the design load, and the height of the flange 32 is mainly a fixing device to prevent the top plate 31 from torsion. Such as figure 2 As shown, the prefabricated assembly device 3 also includes a cushion 2 , wherein a part of the cushion is installed between the roof 31 and the culvert 1 , and the remaining cushion is installed between the flange 32 and the culvert 1 . This can buffe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com