A kind of mo/ni/co/p/c composite material and its preparation method and application

A composite material and mixed solution technology, applied in chemical instruments and methods, water/sludge/sewage treatment, biological water/sewage treatment, etc., can solve problems such as inability to ensure hydrogen production effect, cumbersome domestication operation, and complicated operation process. , to achieve the effect of low price of raw materials, easy to be widely used and popularized, and simple operation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A Mo / Ni / Co / P / C composite material is prepared by the following method: in a three-electrode system, a carbon-based substrate is used as a working electrode, a platinum mesh is used as an auxiliary electrode, and Ag / AgCl is used as a reference electrode. The electrochemical workstation is connected, and the concentration is a mixed solution of 30g / L nickel sulfate, 20g / L sodium hypophosphite, 10g / L nickel chloride, 30g / L boric acid, 30g / L cobalt chloride and 40g / L sodium molybdate The constant potential deposition is carried out in the deposition process, and the magnetic stirring is always carried out during the deposition process. The initial potential of the electroplating is set to -1.5V on the working electrode, the electroplating time is 5min, and the electroplating temperature is set to 25 ° C. Finally, the power is turned off, and the Mo is obtained. / Ni / Co / P / C composite material.

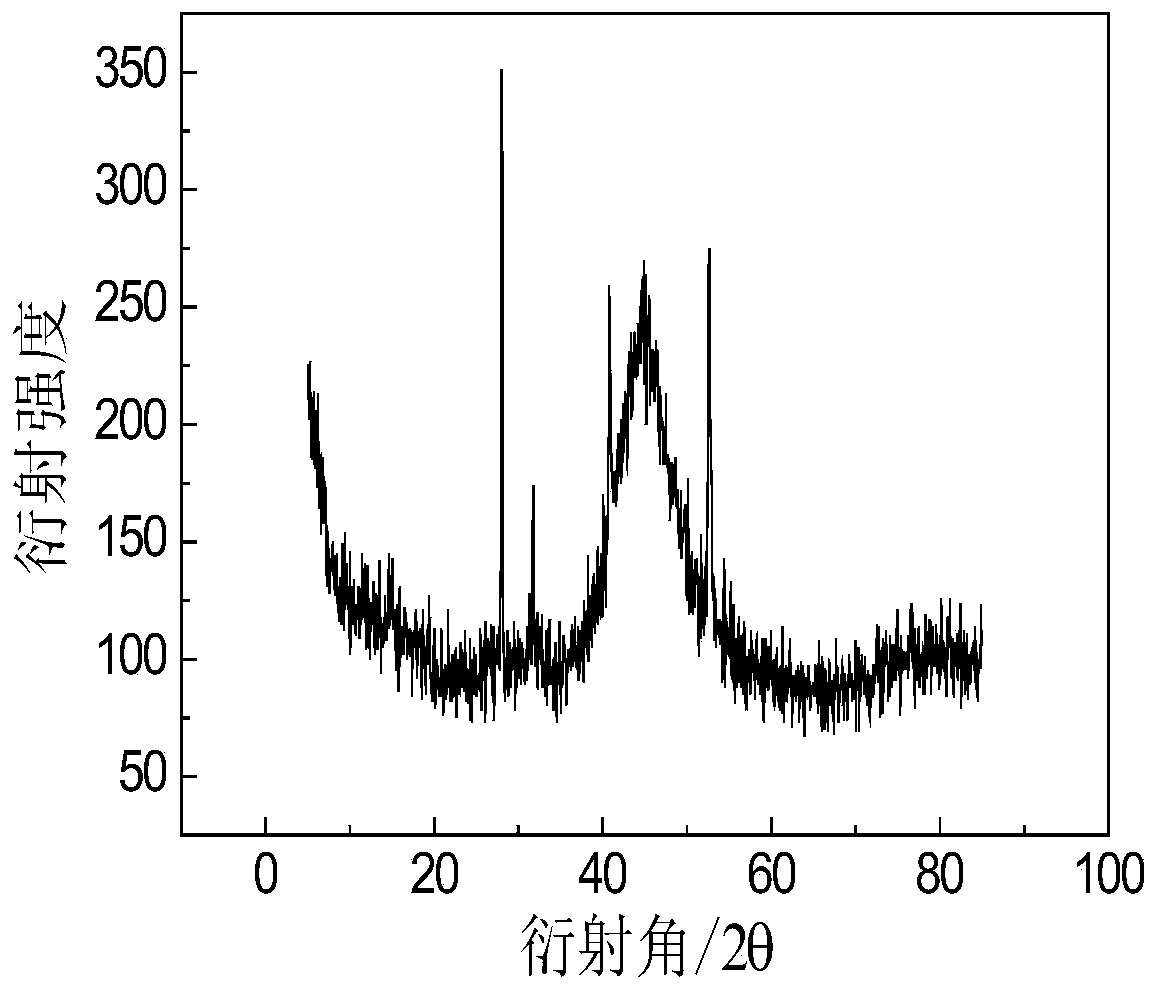

[0045] For further characterizing the Mo / Ni / Co / P composite material in the presen...

Embodiment 2

[0055] A Mo / Ni / Co / P / C composite material is prepared by the following method: in a three-electrode system, a carbon-based substrate is used as a working electrode, a platinum mesh is used as an auxiliary electrode, and Ag / AgCl is used as a reference electrode. The electrochemical workstation is connected, and the concentration is a mixed solution of 50g / L nickel sulfate, 30g / L sodium hypophosphite, 15g / L nickel chloride, 33g / L boric acid, 40g / L cobalt chloride and 45g / L sodium molybdate The constant potential deposition is carried out in the deposition process, and the magnetic stirring is always carried out during the deposition process. The initial potential of the electroplating is set to -1.2V on the working electrode, the electroplating time is 20min, and the electroplating temperature is set to 30°C. Finally, the power is turned off, and the Mo is obtained. / Ni / Co / P / C composites.

[0056] Described carbon nanotube is through following pretreatment:

[0057] The first st...

Embodiment 3

[0065] A Mo / Ni / Co / P / C composite material is prepared by the following method: in a three-electrode system, a carbon-based substrate is used as a working electrode, a platinum mesh is used as an auxiliary electrode, and Ag / AgCl is used as a reference electrode. The electrochemical workstation is connected, and the concentration is a mixed solution of 70g / L nickel sulfate, 40g / L sodium hypophosphite, 20g / L nickel chloride, 35g / L boric acid, 50g / L cobalt chloride and 50g / L sodium molybdate The constant potential deposition is carried out in the deposition process, and the magnetic stirring is always carried out during the deposition process. The initial potential of the electroplating is set to -1V on the working electrode, the electroplating time is 30min, and the electroplating temperature is set to 35 ° C. Finally, the power is turned off, and the Mo / Ni / Co / P / C composite material.

[0066] Described natural graphite is through following pretreatment:

[0067] The first step i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com